Powder thixoforming preparation method of Al3Tip/Al-based in-situ composite material

A composite material and thixotropic forming technology, which is applied in the field of preparation and molding of metal matrix composite materials, can solve the problems of long process flow, high reaction temperature, poor tissue compactness, etc., and achieve simple process, low material cost, reinforced good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0007] The invention is Al 3 Ti p / Al-based self-generated composite material powder thixomorphing preparation method, the steps are: mix pure titanium powder and aluminum alloy powder evenly by ball milling, cold press in a press to form a preform, and put the preform into a vacuum furnace. The alloy is heated in the semi-solid temperature range until the reaction is completed, and after the reaction is completed, it is taken out and placed in a preheated mold for thixotropic deformation, that is, the Al alloy is prepared. 3 Ti p / Al-based composites.

[0008] According to the above-mentioned preparation method, the mixing ball milling time of pure titanium powder and aluminum alloy powder is 0.5h-1h, the ball-material ratio is 5:1, and the rotation speed is 100r / min.

[0009] According to the above-mentioned preparation method, the pressure range for pressing the preform is 144MPa-224MPa.

[0010] According to the above-mentioned preparation method, the semi-solid temper...

Embodiment 1

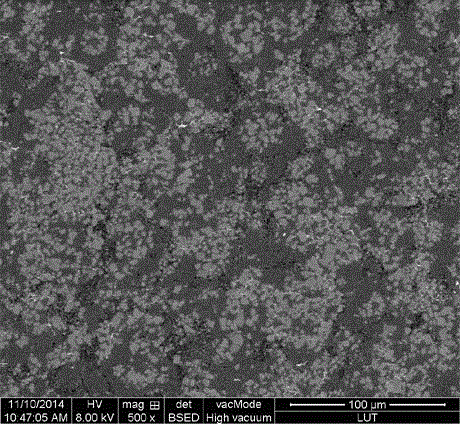

[0016] This example uses Ti powder with a particle size of 0-20um and 2024Al alloy powder with a particle size of 10-20um as raw materials to prepare Al with a volume fraction of 10%. 3 Ti p Reinforced 2024Al-based autogenous composites. Through conversion, Al with a volume fraction of 10% is generated 3 For Ti, the weight ratio of Ti powder to 2024 aluminum alloy powder is 1:22. According to this ratio, the raw material powder is weighed, ball milled in a ball mill for 40 minutes (ball-to-material ratio 5:1), and then put into a press to press with a pressure of 192MPa. To form a Φ50×30mm preform, heat the preform in a vacuum furnace at 655°C for 8h, take it out and put it into a mold at a temperature of 300°C for thixotropic deformation. its organized as figure 1 , 2 shown.

Embodiment 2

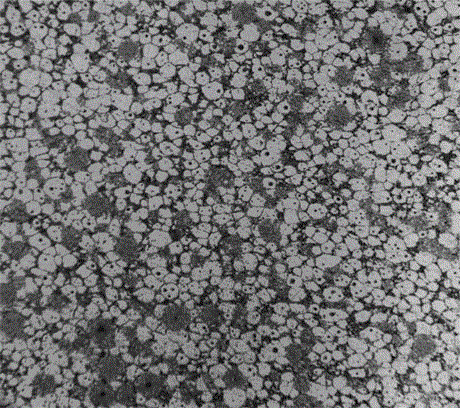

[0018] Use Ti powder with a particle size of 0-20um and 2024Al alloy powder with a particle size of 10-20um as raw materials to prepare Al with a volume fraction of 10% 3 Ti p Reinforced 2024Al-based autogenous composites. Through conversion, Al with a volume fraction of 10% is generated 3 For Ti, the weight ratio of Ti powder to 2024 aluminum alloy powder is 1:22. According to this ratio, the raw material powder is weighed, ball milled in a ball mill for 40 minutes (ball-to-material ratio 5:1), and then put into a press to press with a pressure of 192MPa. To form a Φ50×30mm preform, heat the preform in a vacuum furnace at 645°C for 9 hours, take it out and put it into a mold at a temperature of 300°C for thixotropic deformation. its organized as image 3 , 4 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap