Circumferential-winding-type automobile generator stator winding arrangement method with high heat dissipation rate

A technology for automotive generators and layout methods, applied to electromechanical devices, shape/style/structure of winding insulation, shape/style/structure of winding conductors, etc., can solve the problem of reduced efficiency of magnetic field waveform distortion, limited slot fullness, and coil Loose and other problems, to achieve the effect of reducing the cost of assembly process, reducing the DC resistance, and reducing the length of the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

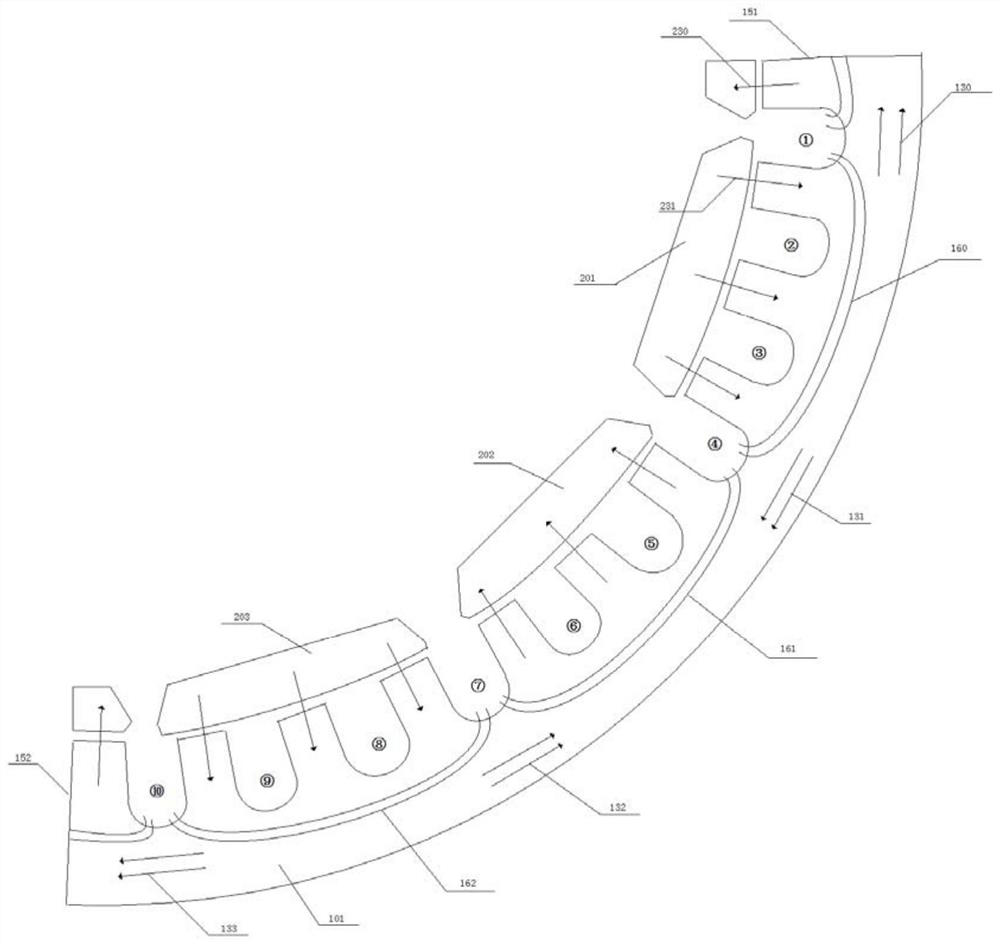

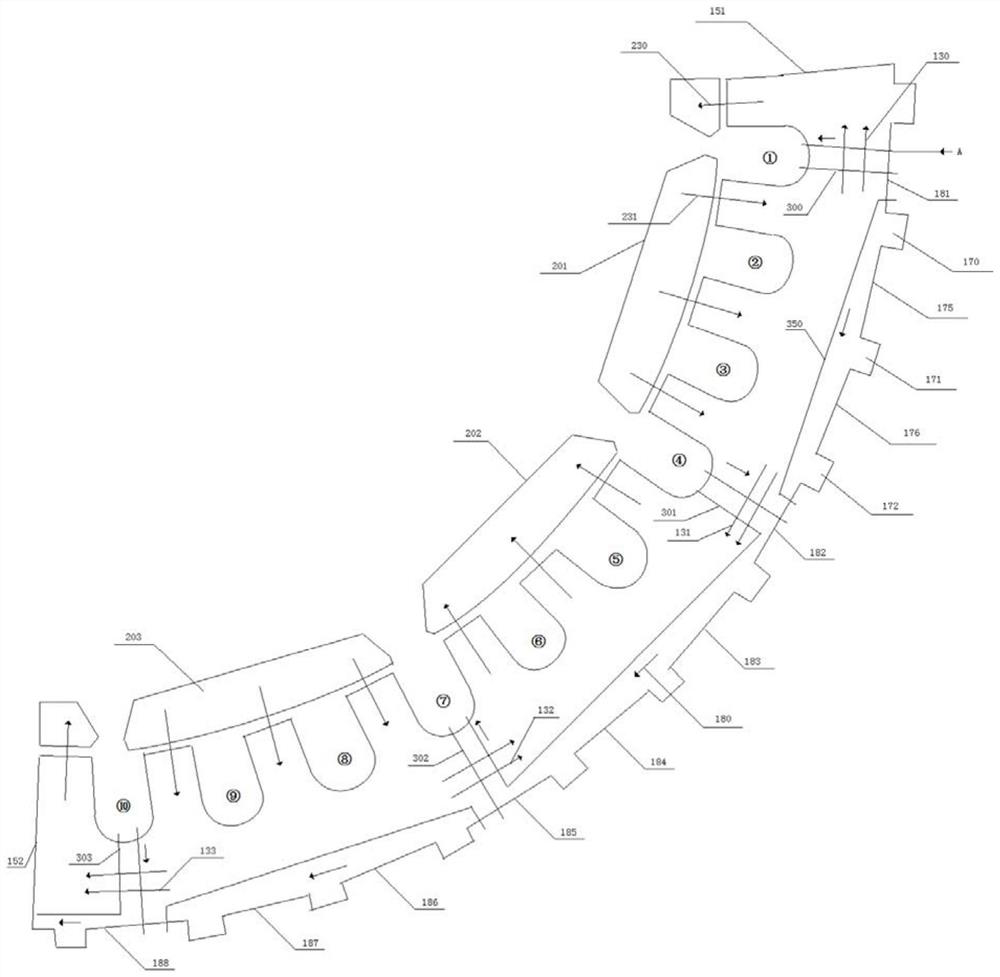

[0031] This embodiment is a method for arranging stator windings of a circumferentially-wound high heat dissipation rate automotive generator. figure 1 The magnetic field on the circumference of the stator winding will be differentiated into two types of magnetic field lines. One is when the rotor magnetic pole 201 is N-level as shown in the figure, it is aimed at the three magnetic poles between the stator slot circuit ①--④ The magnetic lines of force are divided into two directions on the circumference of the stator, combined with the attached image 3 It can be seen that one path is divided into the circumferential iron core passing upwards between the inner and inner grooves ① and the corresponding outer grooves 181, and its magnetic field lines are shown as 130 in the figure, and the other path is divided into downwards passing through the inner grooves ④ and the outer grooves. Circumferential iron core between 182, its magnetic field line is shown as 131 among the figure...

Embodiment 2

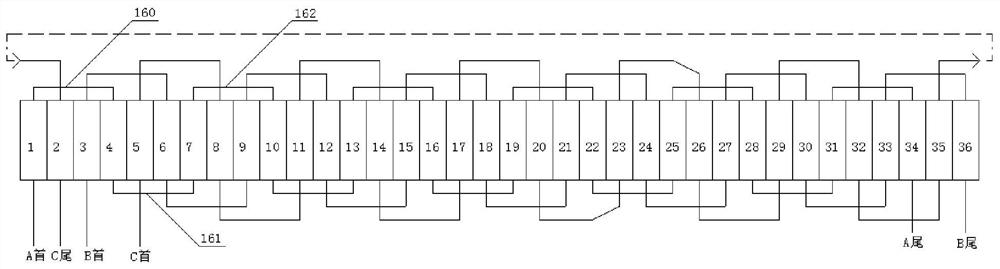

[0037] Such as Figure 4 As shown in the figure, the generator stator core and winding structure using this circumferential winding high heat dissipation rate automotive generator stator winding arrangement method, the stator includes an axially slotted stator core and stator windings, and the stator core is in a circular structure 1. The inner circle side of the circular structure is provided with a number of inner grooves along the axial direction, and the outer circle side of the circular structure is covered with an insulating support with several outer grooves arranged in the axial direction. The insulating support is close to the outer wall of the stator core circumference , the plastic bracket can be used, or the bracket can be processed directly on the stator core by a process such as injection molding. The outer edge of the bracket has an outer groove and an outer tooth corresponding to the corresponding inner groove, such as Figure 4 As shown, the part enclosed betw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap