Energy-saving pulping cooking sequence interlock control system

An interlocking control and control system technology, applied in the field of papermaking industry, can solve the problems affecting the stable operation of papermaking equipment, the process requirements are very different, and the cooking quality cannot be guaranteed, so as to reduce the consumption of bleaching chemicals, the system composition is flexible, and the Yield-friendly effect

Active Publication Date: 2015-03-25

CHINA LIGHT IND NANNING DESIGN ENG

View PDF6 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the influence of factors such as the proficiency of the operator and the sense of responsibility of the operator, the actual pressure boost curve often differs greatly from the process requirements, resulting in an increase in steam consumption, a decrease in the slurry yield, and in severe cases, a decrease in the steam pressure of the main pipe. Affect the stable operation of papermaking equipment

At the same time, affected by the

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

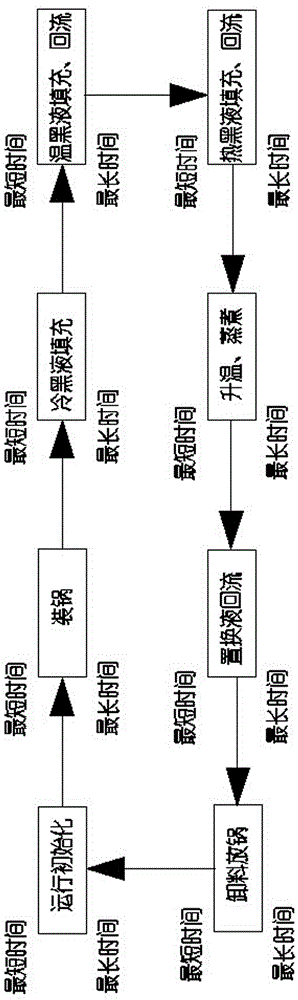

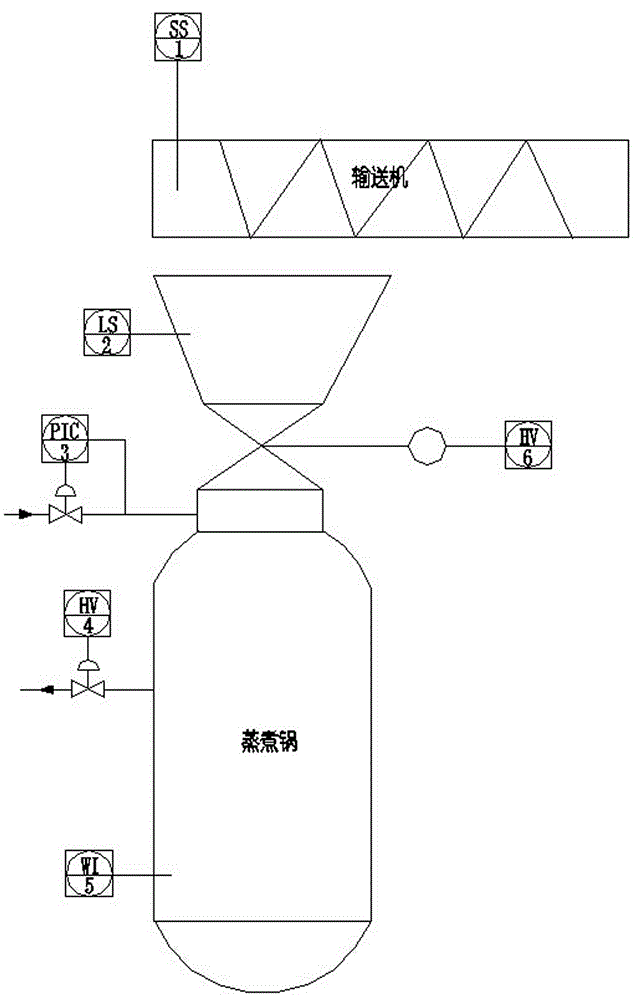

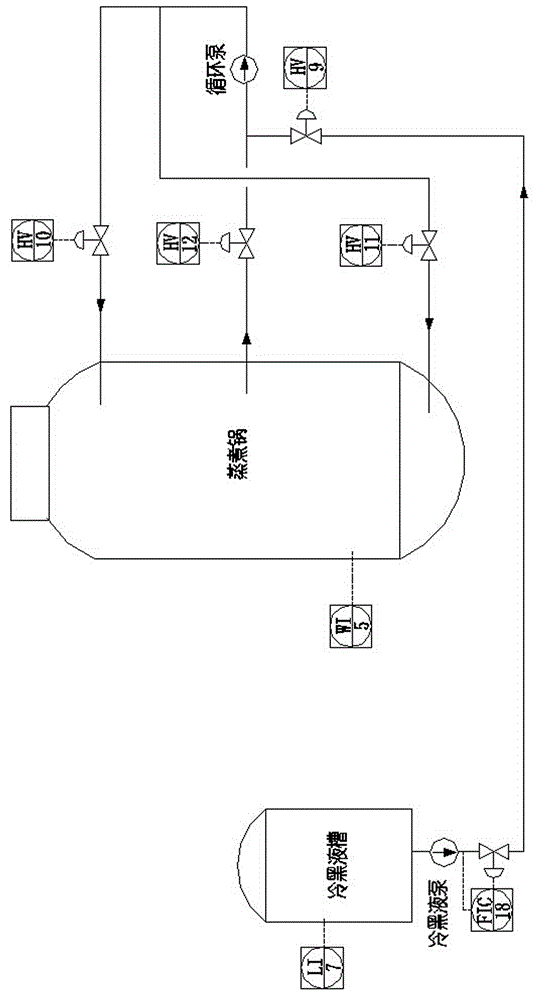

The invention discloses an energy-saving pulping cooking sequence interlock control system. A distributed control system (DCS) is used to control the process, and sequence interlock control is adopted for mutual close connection, the locking settings of all valves used in sequence control are normal close state, the execution time of each sequence control is set on the distributed control system (DCS), valves of each sequence are sequentially opened according to the preset time when the system runs to achieve feeding sequence control, cold black liquor filling sequence control, warm black liquor filling and return sequence control, hot black liquor filling and return sequence control, heating and cooking sequence control, replacement fluid return sequence control and discharging sequence control. The energy-saving pulping cooking sequence interlock control system disclosed by the invention has the advantages that the controllability and reliability of energy-saving cooking can be effectively improved, the economic benefit can be improved, and misoperation and accident rate can be reduced.

Description

technical field [0001] The invention relates to the technical field of papermaking industry, in particular to an energy-saving papermaking pulping cooking sequence interlocking control system which adopts high-precision automatic detection instruments and uses a distributed control system (DCS) to continuously and dynamically monitor production process parameters. Background technique [0002] The paper industry is an important traditional industry closely related to the development of the national economy. According to statistics in the mid-1990s, the world’s paper industry’s total output value accounted for about 2.5% of the total industrial output value, and the trade volume of paper products accounted for about the world’s total trade volume. 2%. As an important carrier of information exchange, paper and cardboard are the most important packaging materials in the circulation process of industrial products and daily hygienic consumer goods indispensable to people in moder...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D21C3/22

CPCD21C3/228

Inventor 丁泽京葛友周锡政许东飘张杰

Owner CHINA LIGHT IND NANNING DESIGN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com