A low-grade thermal energy power generation method and device

A technology for thermal power generation and power generation devices, applied in electrical components and other directions, can solve the problems of high development difficulty, large pump power consumption and reduction, and achieve the effect of simplifying the power generation process and equipment, high energy conversion efficiency, and simple working cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation process of the present invention will be described in detail below in conjunction with the technical scheme and accompanying drawings.

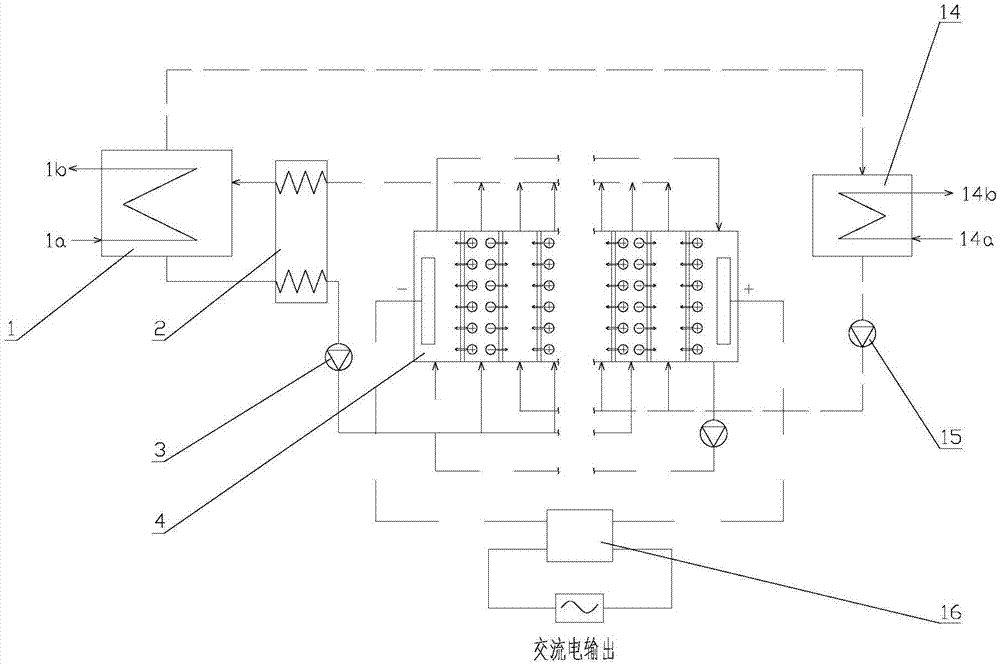

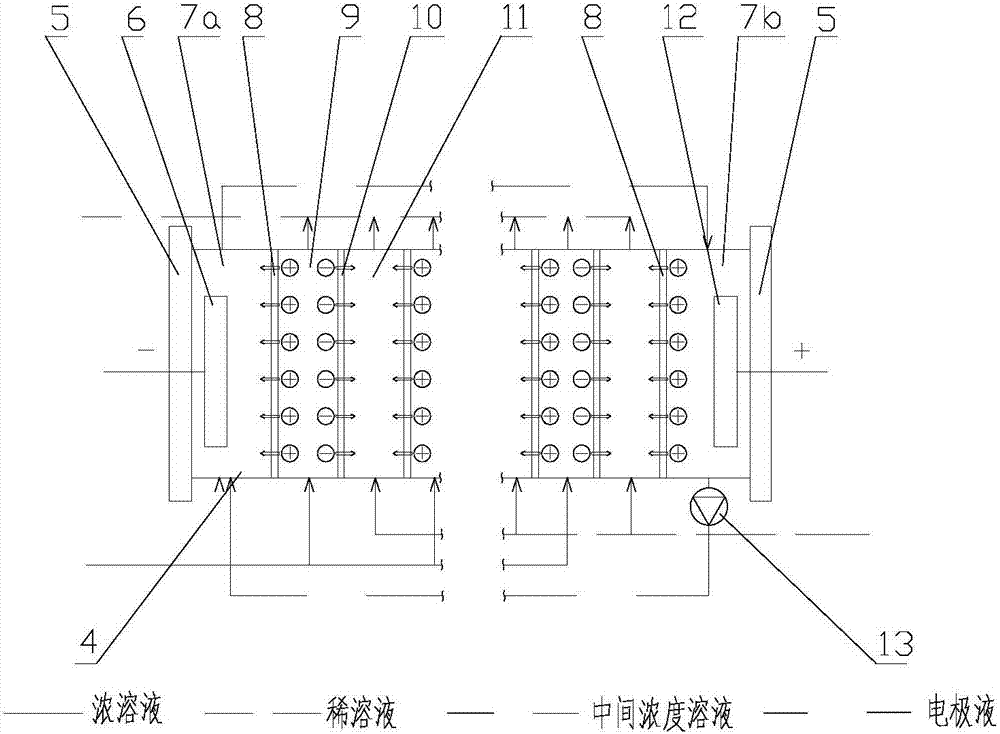

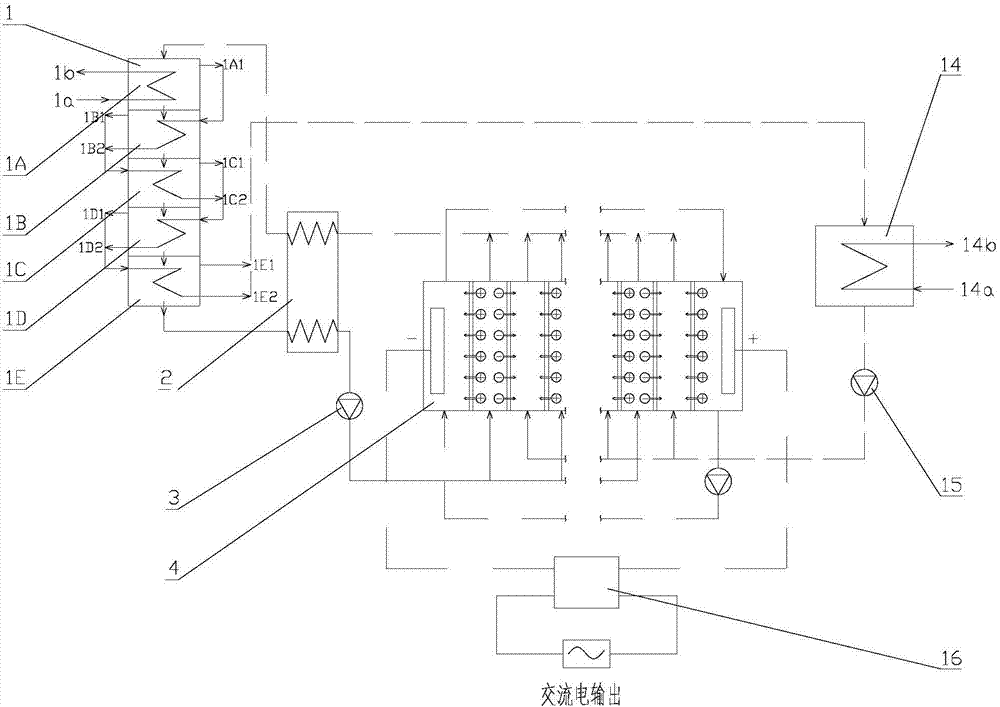

[0024] attached figure 1 It is a working cycle process of a single-effect low-grade thermal power generation method without energy storage function, in which figure 2 It is a schematic diagram of the structure of the RED battery stack 4 in the working cycle; its working process is: low-grade thermal energy stream 1a such as low-temperature hot water, low-pressure water vapor or low-temperature hot gas flows through the generator 1, and the working solution is heated in the generator 1 (such as NaCl aqueous solution, etc.), the low-grade thermal energy stream 1a flows through the generator 1 to release heat and then flows out of the generator 1; after the NaCl aqueous solution obtains heat in the generator 1, the low boiling point component (water) is partially vaporized under low pressure ,, separated from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com