Construction method of prestressed concrete pipe pile

A technology of concrete pipe piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, foundation structure tests, etc., can solve the problems of long preparation time, high cost, and reduced efficiency, so as to shorten the pile connection time and shorten the construction period , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

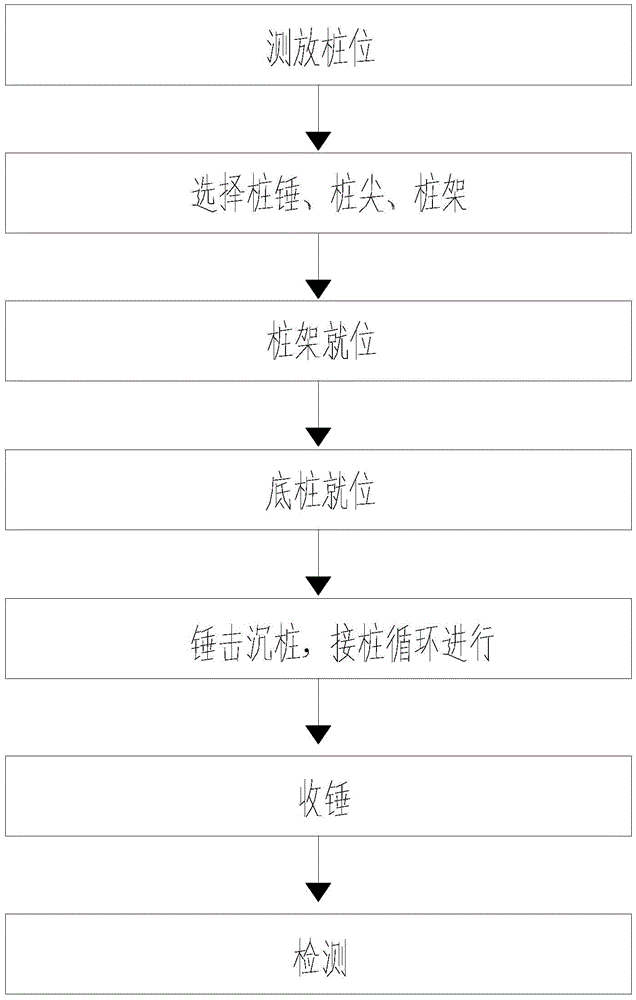

Method used

Image

Examples

Embodiment 1

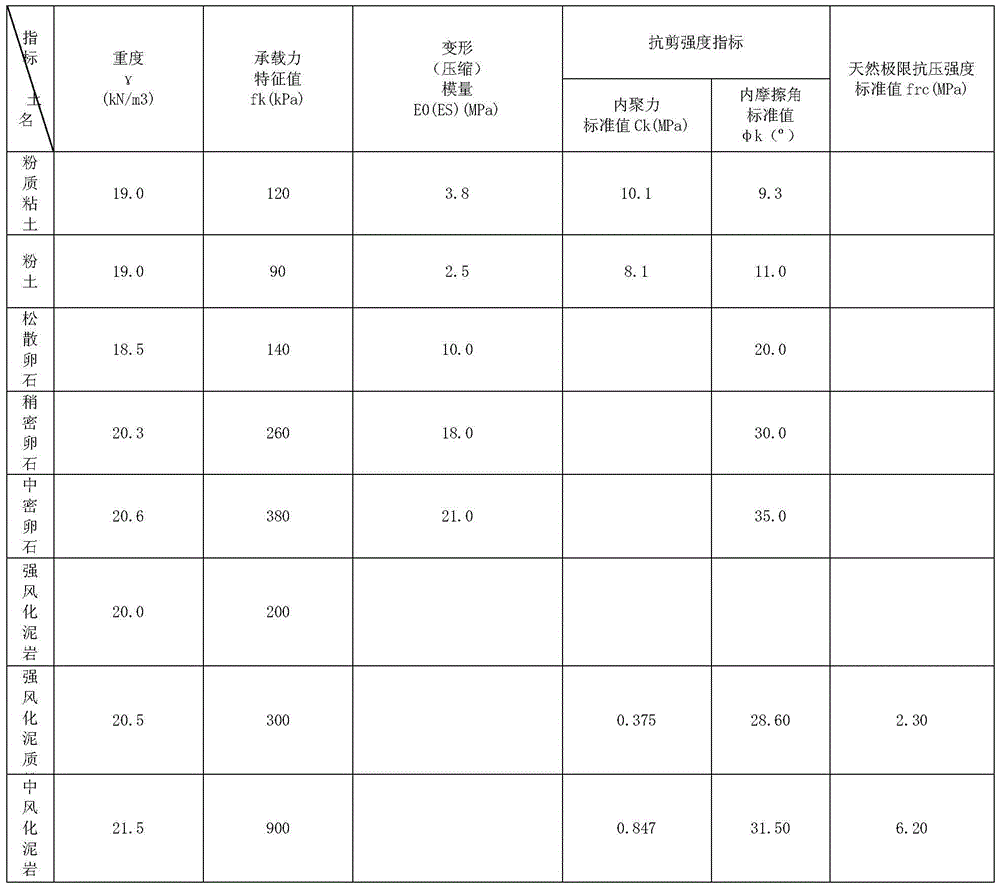

[0023] This embodiment takes the Guangyuan North Sichuan Mobile Communication Hub Project of China Railway 23rd Bureau Group No. 8 Engineering Co., Ltd. as an example, and the construction site is a group of Wanyuan Village, Dongba Office, Lizhou District, Guangyuan City. Including communication hub building, production management building, oil machine room, guard, outdoor general and other individual projects. The total building area of this project is about 4122.04m2, the total construction area is about 16199.18m2, and the reasonable service life is 50 years. The building height is 23.55m, the total construction area is about 6235.27m2, the seismic rating of the frame is Class II, the foundation design class is Class C, and the prestressed pipe pile foundation; Five floors, building height 23.55m, total construction area is about 8851.86m2, the seismic grade of the frame is grade 3, the foundation design grade is grade C, prestressed pipe pile foundation.

[0024] The oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com