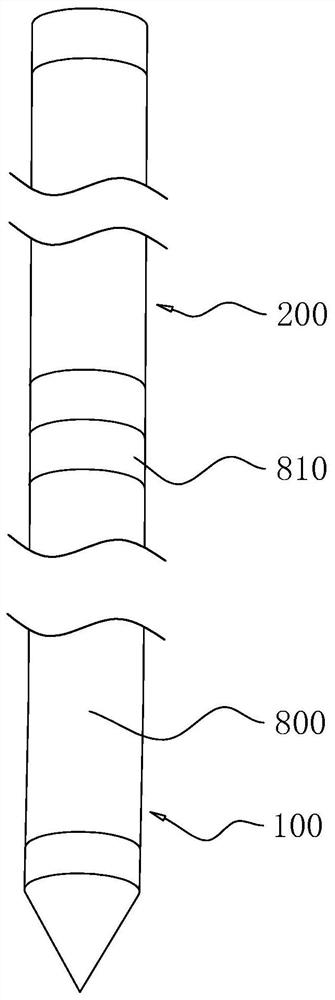

Construction method and positioning hoop of prestressed pipe pile

A technology of prestressed pipe piles and construction methods, applied in the direction of sheet pile walls, manufacturing tools, foundation structure engineering, etc., can solve the problems of low construction work efficiency and long duration of operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

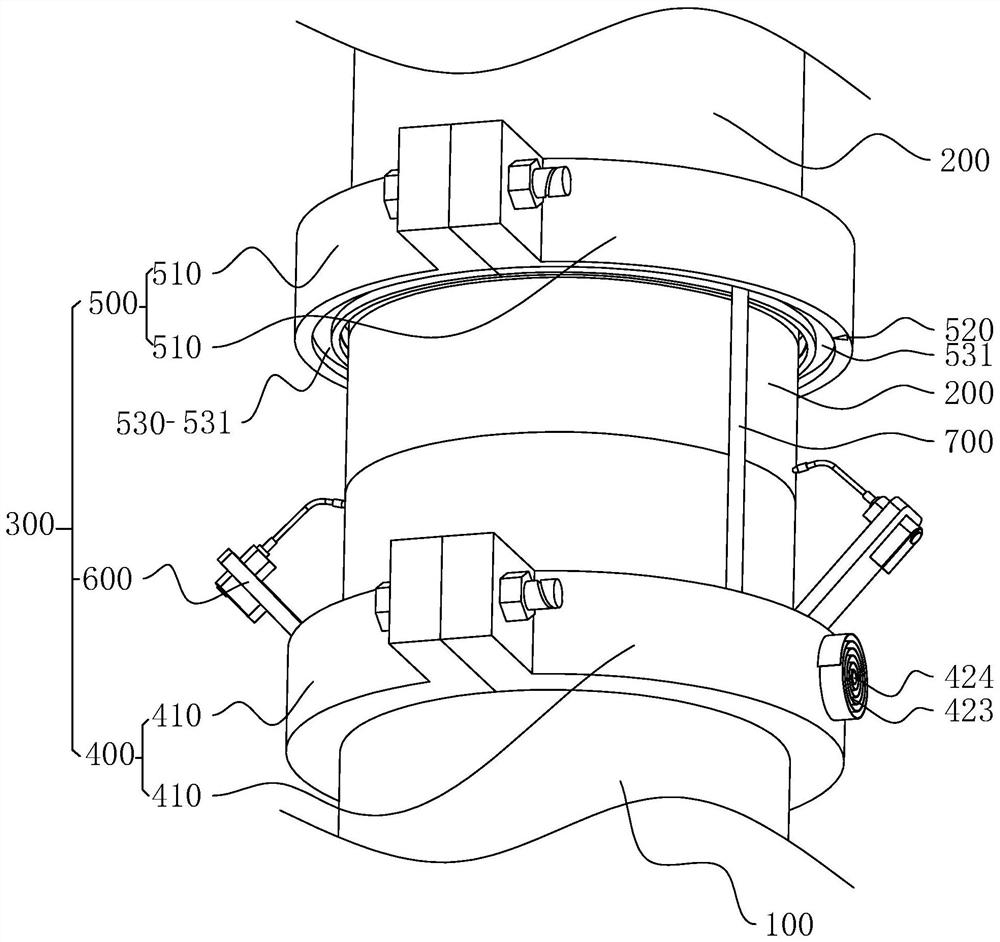

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

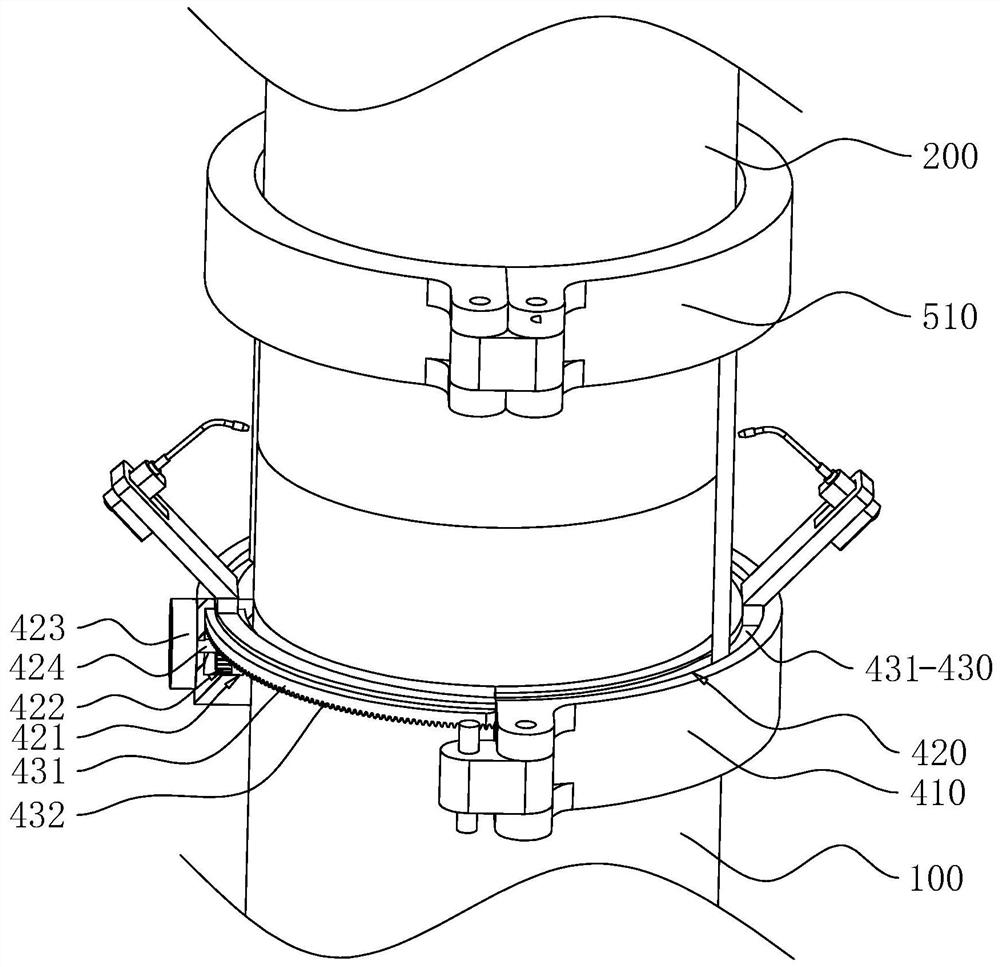

[0048] refer to figure 2 , is a positioning hoop for prestressed pipe piles disclosed in the present invention, comprising a positioning ring 400 divided into two semi-annular positioning plates 410 .

[0049] refer to figure 2 and image 3 One end of the two positioning plates 410 is rotationally connected, the other ends of the two positioning plates 410 are free ends, and the free ends of the two positioning plates 410 are detachably connected by bolts. The side of the positioning ring 400 away from the ground is provided with a sliding groove 420 along its circumference. The sliding groove 420 is set as a T-shaped groove. A sliding ring 430 matching the shape of the sliding groove 420 is arranged in the sliding groove 420. The sliding ring 430 is arranged along the The sliding groove 420 is slidingly connected with the sliding groove 420 circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com