Embedded leak-proof joint

A leak-proof and connecting piece technology, which is applied in waterway systems, indoor sanitary pipeline installations, drainage structures, etc., can solve the problems of joints without water seals, no secondary drainage, and poor water flow, so as to achieve convenient rotation and alignment , smooth water flow, good effect of anti-leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below by specific examples.

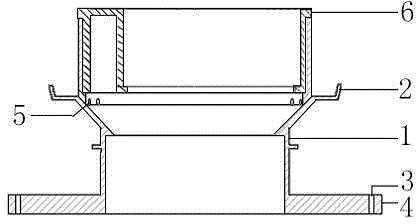

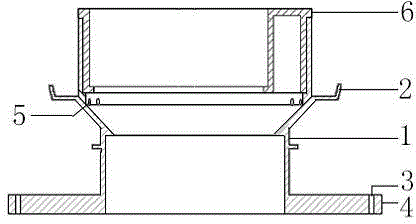

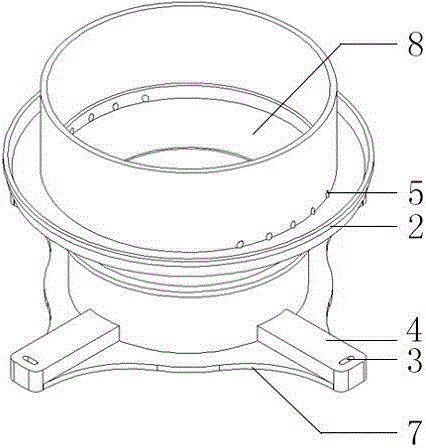

[0019] as attached figure 1 , attached figure 2 As shown, the pre-embedded leak-proof joint of the embodiment includes a leak-proof joint body 1, the upper end of the leak-proof joint body 1 is provided with a water guide groove 2, and a drain hole 5 is provided in the leak-proof joint body to realize the secondary drainage function. The lower end of the leak-proof joint body 1 is provided with a fixing ring, such as image 3 , Figure 5 As shown, the periphery of the fixed ring is provided with a plurality of chamfered round edges 7 and fixed feet 4, the chamfered rounded edges 7 and the fixed feet 4 alternate with each other, and the fixed feet 4 are provided with a fixed hole 3, and the fixed hole 3 is an elongated fixed hole , the length is 8mm-12mm, the width is 2mm-5mm, and the concentric circles are made into elongated holes at the fixed position, which is convenient for nailing. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com