Pipeline installation and construction method for rocket rp-1 propellant delivery system

A conveying system, RP-1 technology, applied in the direction of jet propulsion devices, rocket engine devices, auxiliary devices, etc., can solve problems such as high cost, low construction efficiency, and potential safety hazards, so as to prevent intergranular corrosion and solve assembly problems. Good effect of welding and heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

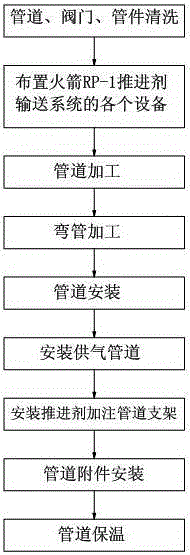

[0054] Such as figure 1 As shown, the present invention is mainly applied to rocket propellant, especially the pipeline installation aspect of rocket RP-1 propellant delivery system. When the present invention is applied to the rocket RP-1 propellant delivery system, the process of its implementation is mainly divided into the following parts:

[0055] (1) Cleaning of pipes, valves and fittings

[0056] Pipes, valves and pipe fittings must be degreased and cleaned in strict accordance with the requirements before installation. The cleaning site should be a well-built factory building and a room that can be sealed around the floor. The ventilation conditions should be good. The site environment should be clean and dry. The tools used should be clean. Operators must wear clean work clothes and rubber gloves to prevent Ensure the quality of cleaning work.

[0057] Cleaning agent: industrial alcohol is preferably used in this embodiment.

[0058] Auxiliary tools: PSI pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com