a rotary clutch

A clutch and piston technology, applied in the field of hydromechanical transmission, can solve the problems of increasing the difficulty of installation structure design, increasing the overall length and size of the auxiliary gearbox, etc., to reduce the difficulty of structural design and layout structure design, compact structure, and reduce the number of shafts. To the effect of the length dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

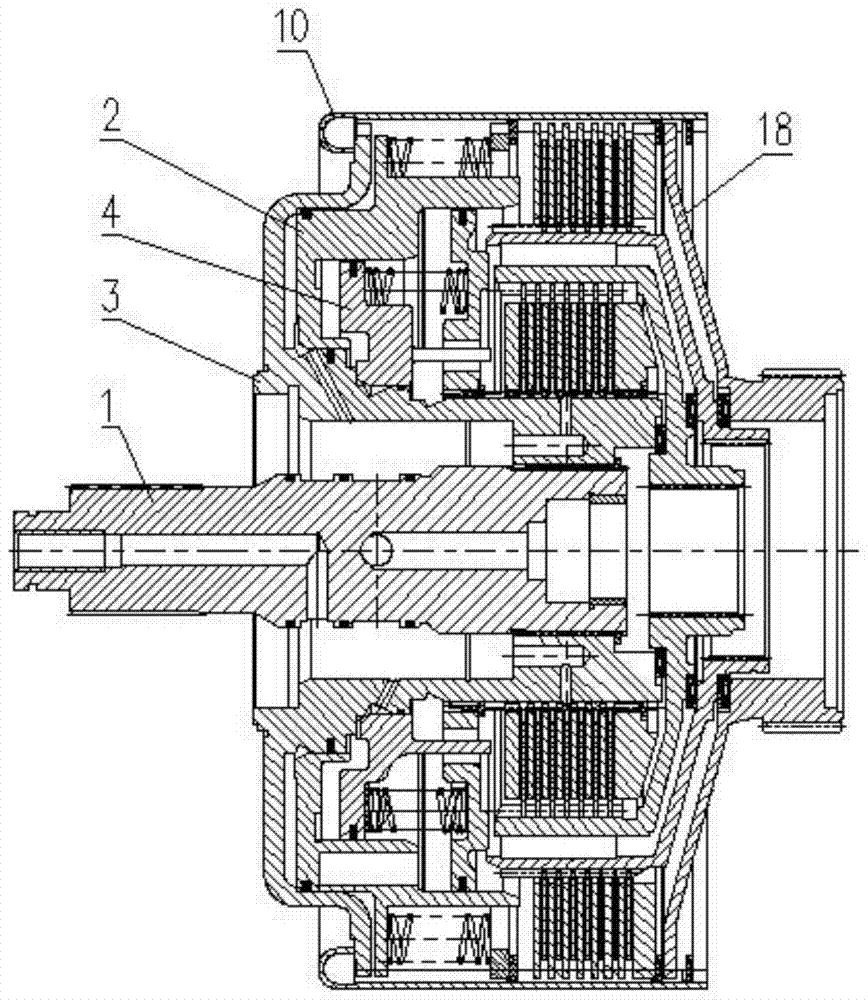

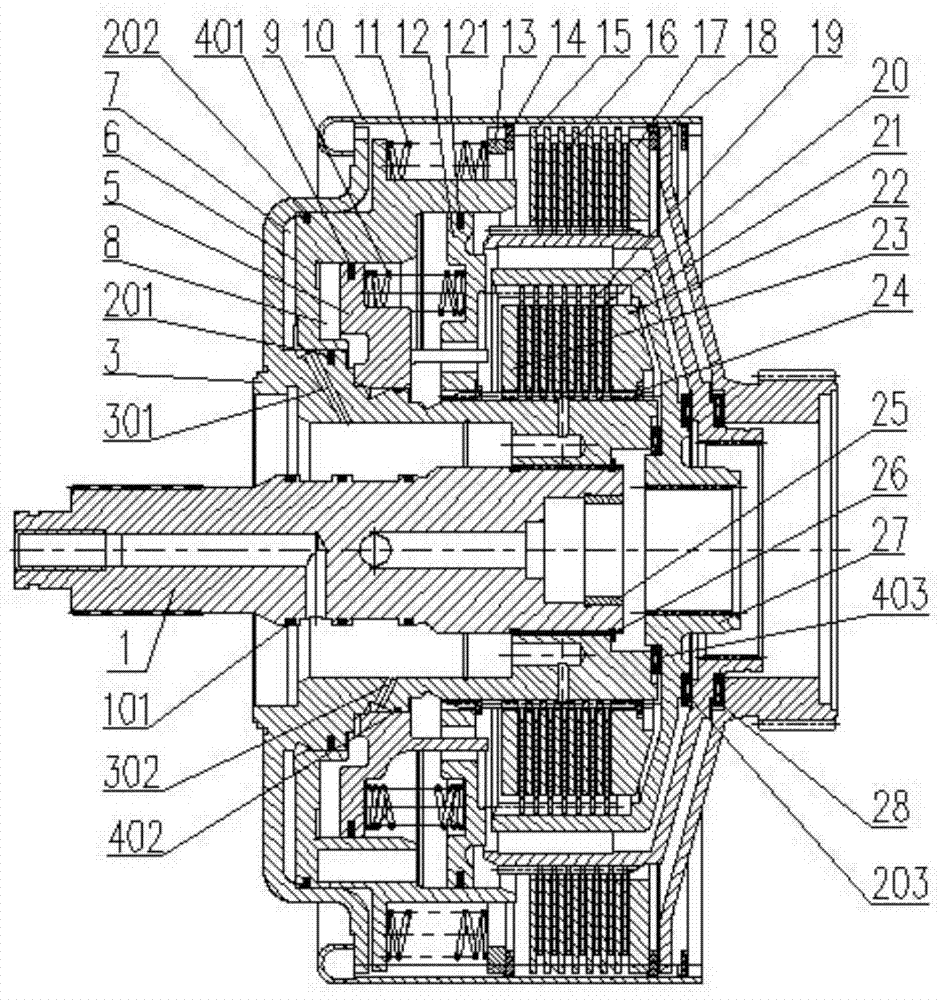

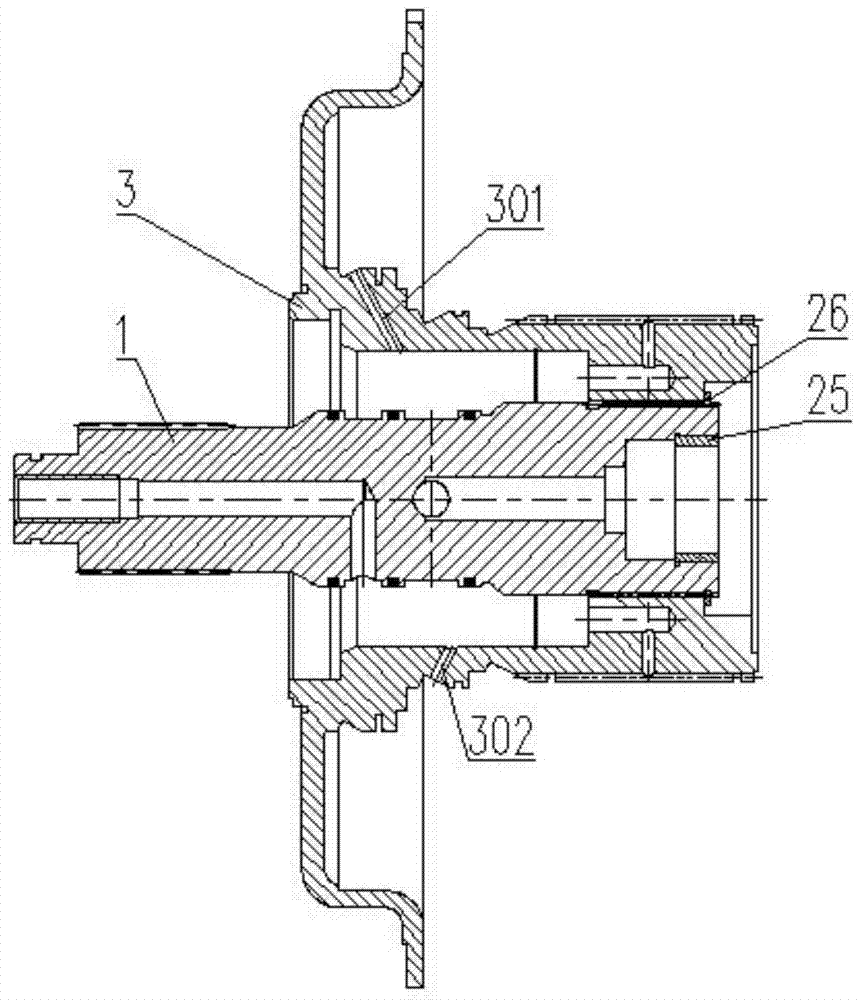

[0031] Embodiment one: if Figure 4 As shown, there are two radial small holes on the driving hub 3, which are used for the lubricating oil of the C2 clutch 4 and the sliding bearing 25 to enter the oil, and the external teeth on the large outer edge of the driving hub 3 and the internal teeth of the ring gear 10 Cooperate; one end of the C1 piston return spring 11 is against the end face of the C1 piston 6, and the other end is against the end face of the C1 piston return spring baffle plate 13; there is a C1 outer friction plates 15 and C1 inner friction plates 16 are staggered with 7 pieces each, the outer teeth of C1 outer friction plates 15 are combined with the inner teeth of inner ring gear 10, and the inner splines of C1 inner friction plates 16 are driven by C1 The external spline fit of the hub 21; the sun gear 18 is installed on the C1 drive hub 21, the external teeth of the sun gear 18 are combined with the internal teeth of the inner ring gear 10, and the sun gear...

Embodiment 2

[0033] Embodiment two: if Figure 5 As shown, the C2 clutch front baffle 23 and the C2 clutch back baffle 22 are all sleeved on the small end of the driving hub 3, and the inner splines are matched with the outer splines at the small end of the driving hub 3, and the right end of the C2 clutch back baffle 22 passes through A clutch retaining ring 24 mounted on the drive hub 3 is axially positioned; between the C2 clutch front baffle 23 and the C2 clutch rear baffle 22, 6 pieces of C2 internal friction plates 19 and 7 pieces of C2 inner friction plates 19 and 7 pieces of C2 are arranged in a staggered manner. The outer friction plate 20, wherein the inner friction plate 19 of C2 cooperates with the outer spline of the small end of the drive hub 3, and the outer friction plate 20 of C2 cooperates with the inner spline of the large end of the drive hub 27 of C2.

[0034] like figure 2 , Figure 5 As shown, when the pressure oil enters the C2 piston drive cylinder 8 through the...

Embodiment 3

[0035] Embodiment three: as figure 2 As shown, when the C1 piston driving cylinder 7 and the C2 piston driving cylinder 8 have no oil pressure, the C1 piston return spring 11 and the C2 piston return spring 9 are in the reset state, and the inner friction plate 16 of C1 and the outer friction plate 15 of C1 are in the reset state. No friction, no friction between C2 outer friction plate 20 and C2 inner friction plate 19, C1 drive hub 21 and C2 drive hub 27 have no torque output, the torque of turbine shaft 1 is transmitted to The sun gear 18 outputs power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com