Pipe jacking machine receiving device and receiving method under high water pressure condition

A technology of receiving device and pipe jacking machine, which is used in mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc., to reduce risks, improve safety, and prevent water leakage and mud leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

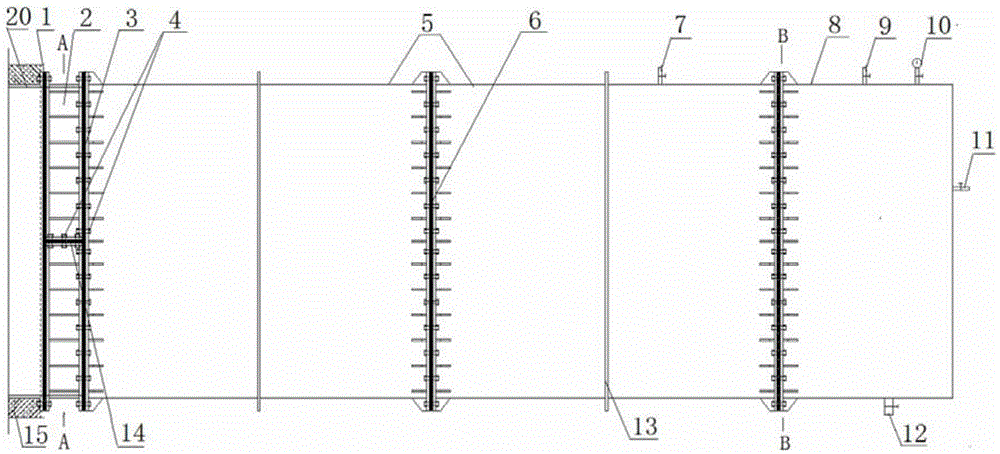

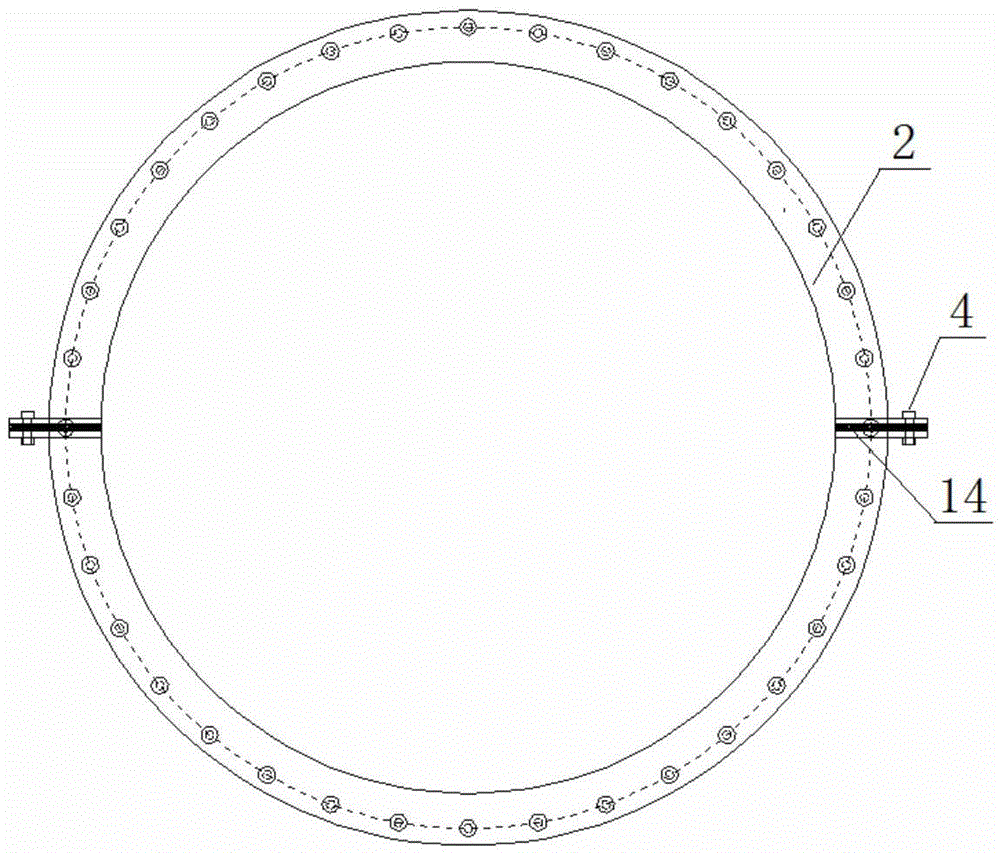

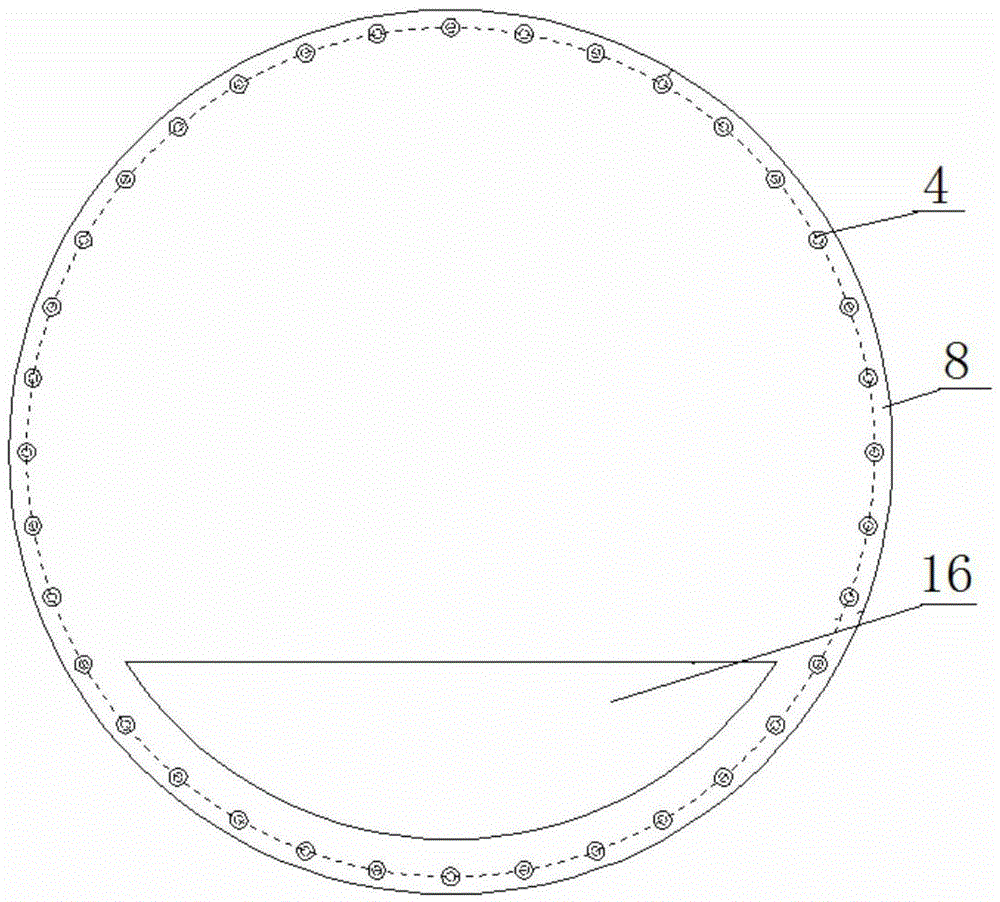

[0034] Embodiment 1: A receiving device for a pipe jacking machine under high water pressure conditions provided by the present invention, its structure is as follows figure 1 shown. Including the orifice pipe 20, the flange pipe 2, the steel casing receiving cabin and the pressure stabilizing cabin 8, and the exhaust valve 7 installed on the steel casing receiving cabin, and the stabilizing pipe 9 installed on the cabin body of the stabilizing cabin 8 , pressure gauge 10, drain valve 11 and overflow valve 12; see figure 2 , the flange tube 2 is formed by sealing the upper and lower semi-circular rings through the bolt 4 and the sealing rubber strip 14, and uses high-strength epoxy resin glue at the joint to strengthen the sealing; the orifice tube 20, the flange tube 2, The steel casing receiving cabin and the pressure stabilization cabin 8 are sequentially connected, and the flange tube 2 end and the Y-shaped rubber sealing ring A1 are fixed on the orifice tube 2 by the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com