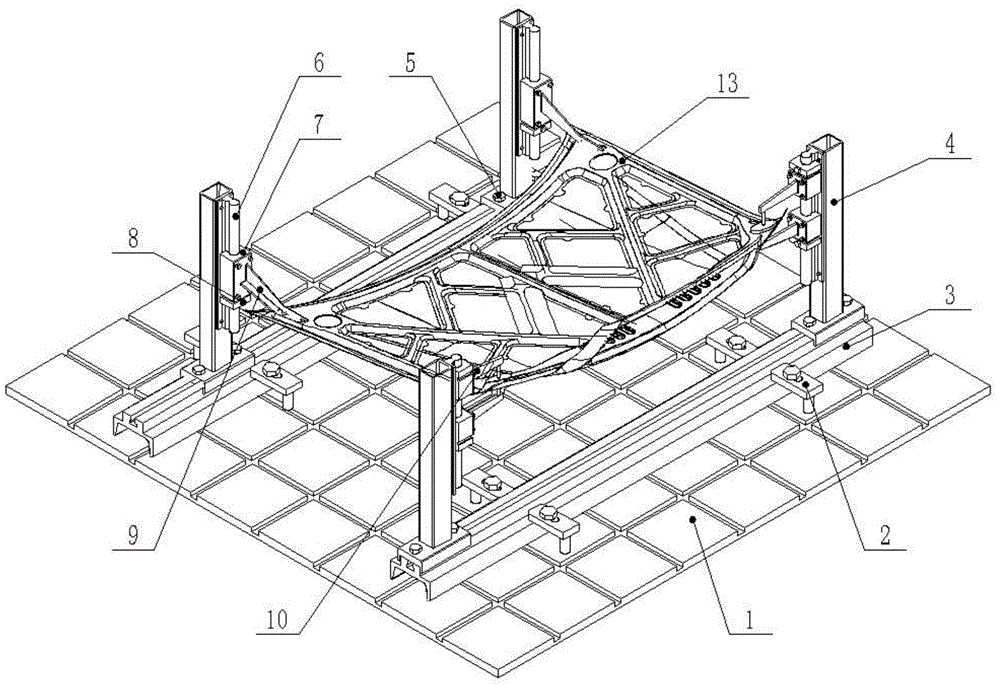

Multifunctional vehicle body cover part stiffness test restraining device

A technology of a body cover and a restraint device, which is applied in the field of automobile static stiffness testing, can solve the problems of positioning and restraint of the test piece, and achieves the effect of simple transformation and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Engine hood stiffness test is divided into torsional stiffness test and bending stiffness test. Among them, the torsional stiffness test is divided into right torsion and left torsion tests according to different loading points. In the example, the right torsion stiffness is taken as an example. The left torsion test has the same principle and operation method of the device, only the left and right positions change.

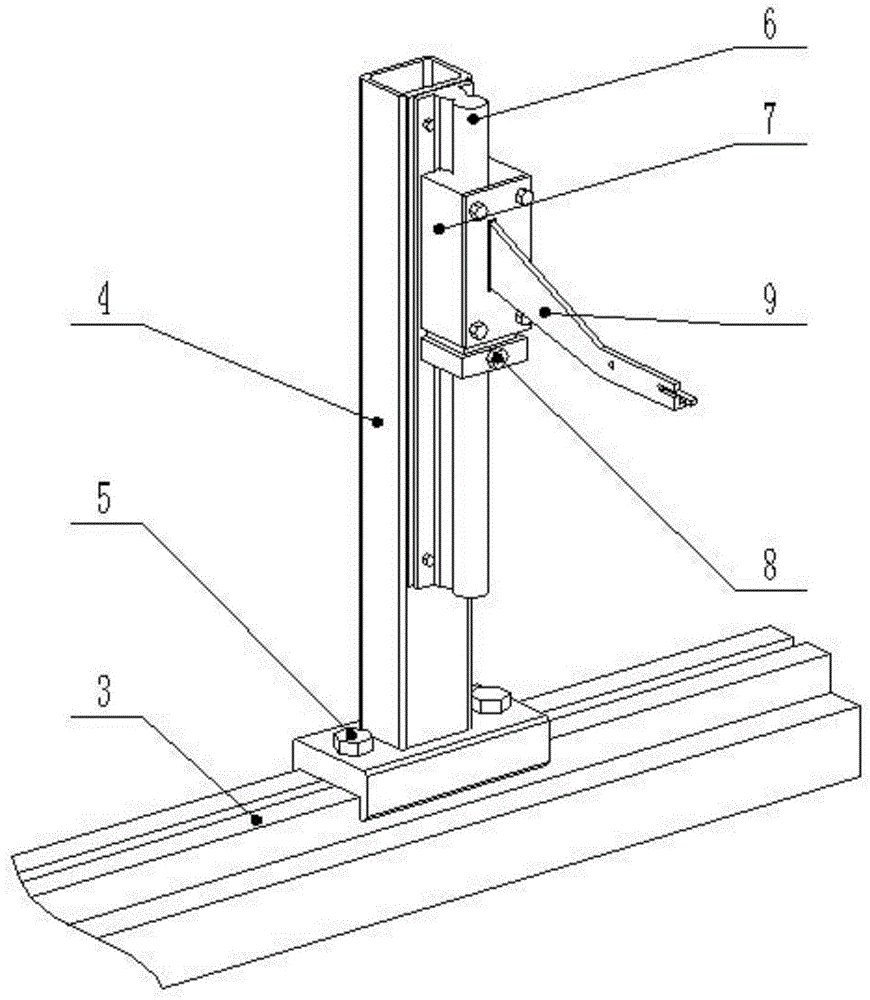

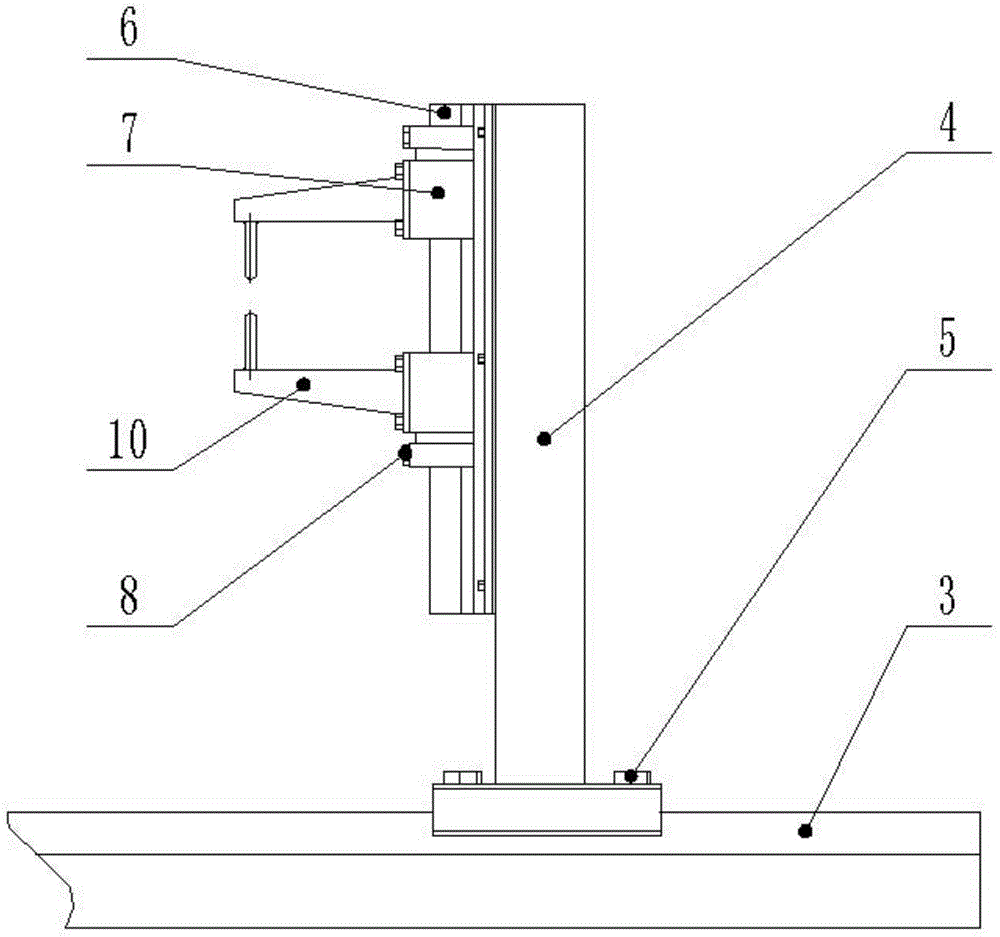

[0026] (1) Measure the X-direction distance between the left and right hood hinges of the engine hood and the left and right buffer blocks, the Y-direction distance between the hood hinge line and the buffer block line, and at the assembly angle The Z-direction distance between the hood hinge and the buffer block;

[0027] (2) According to the measured Y-direction distance results, take the slide rail under the hood hinge fixture joint as a benchmark, and move the other slide rail in parallel so that the hood buffer block fixture joint on the other slide r...

Embodiment 2

[0033] The door stiffness test is divided into window frame stiffness test and torsional stiffness test. Among them, the window frame stiffness test is divided into door frame middle point stiffness test and window corner point stiffness test according to different loading points.

[0034] (1) Measure the X-direction distance between the two door hinges of the car door, the Y-direction distance between the connection line of the two door hinges and the door lock hole, and the Z-direction between the door hinge and the door lock hole at the assembly angle distance;

[0035] (2) According to the measured Y-direction distance results, take the slide rail under the door hinge fixture joint as the benchmark, and move the other slide rail in parallel to make the distance between the door lock fixture joint on the other slide rail and the door hinge fixture joint is the measured distance in the Y direction, and fix the slide rail with a pressure plate;

[0036] (3) According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com