Dynamic sealing structure of material tester resistant to high-low temperature high-pressure hydrogen gas environment

A dynamic sealing structure, high-pressure hydrogen technology, applied in the direction of analysis materials, measuring devices, instruments, etc., can solve the problems of reducing the reliability of dynamic sealing, dynamic sealing difficulties, leakage, etc., to improve reliability and service life, and avoid dynamic sealing piece of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

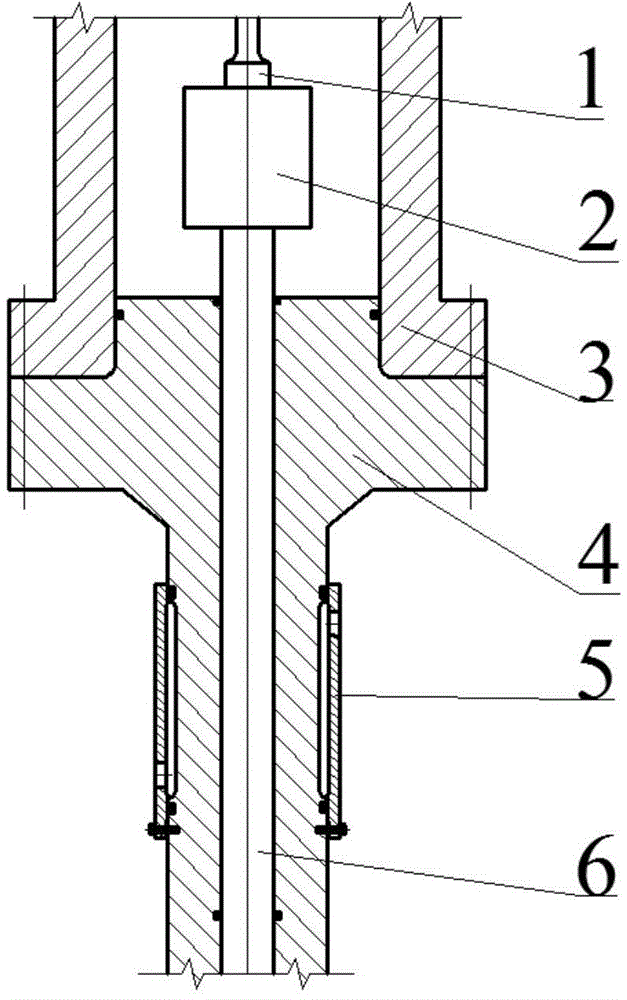

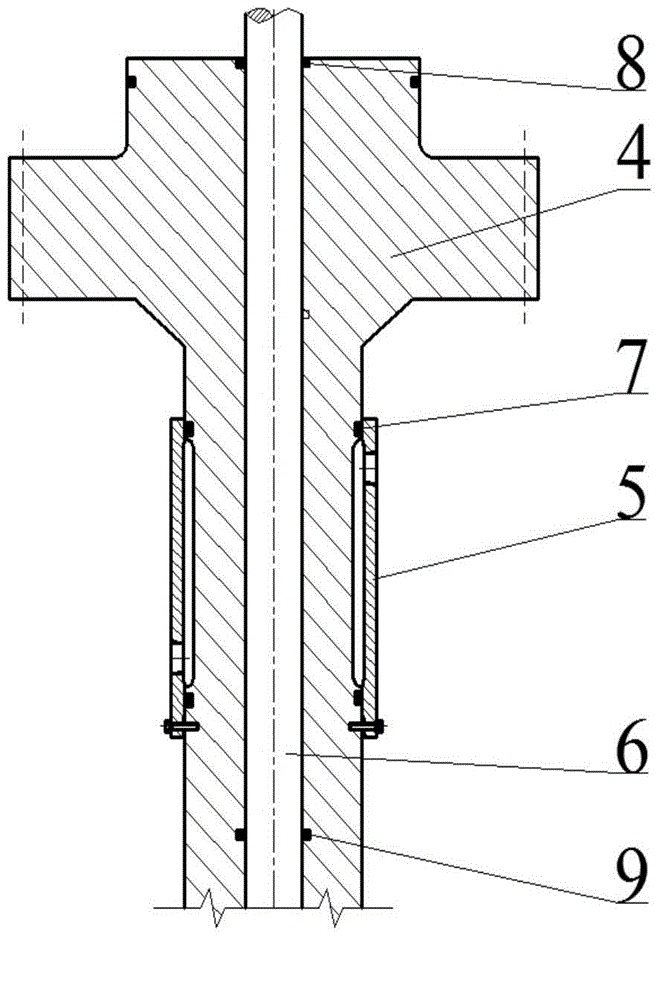

[0017] The dynamic sealing structure of the high-low temperature, high-pressure hydrogen environment-resistant material testing machine in this embodiment includes an environmental box body 3, an environmental box sealing seat 4 and a loading rod 6, and the upper surface of the environmental box sealing seat 4 has a boss structure. The boss structure cooperates with the shape of the opening end of the environmental box 3 to realize the sealing of the environmental box 3 .

[0018] The bottom of the environmental box seal seat 4 has a tubular part extending downwards, and the inside has a through hole through which the loading rod 6 extends into the inside of the environmental box 3; the loading rod 6 and the A guide ring 8 and a dynamic seal 9 are respectively arranged on the gap cylindrical surface of the environmental box seal seat 4; the use of the guide ring 8 and the dynamic seal 9 makes the loading rod 6 not in direct contact with the environmental box seal seat 4; the gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com