Optical cable branching distribution cabinet

A wiring box and optical cable technology is applied in the installation field of power communication optoelectronic integrated wiring box to achieve the effects of reducing work difficulty, improving signal attenuation and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

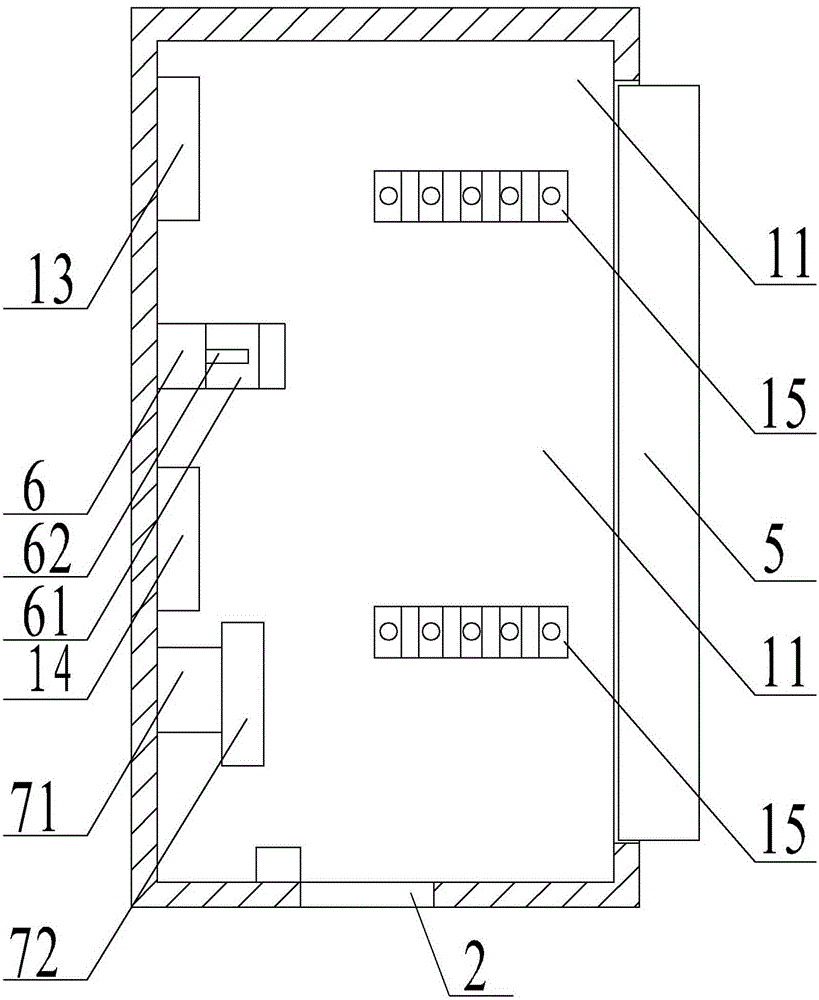

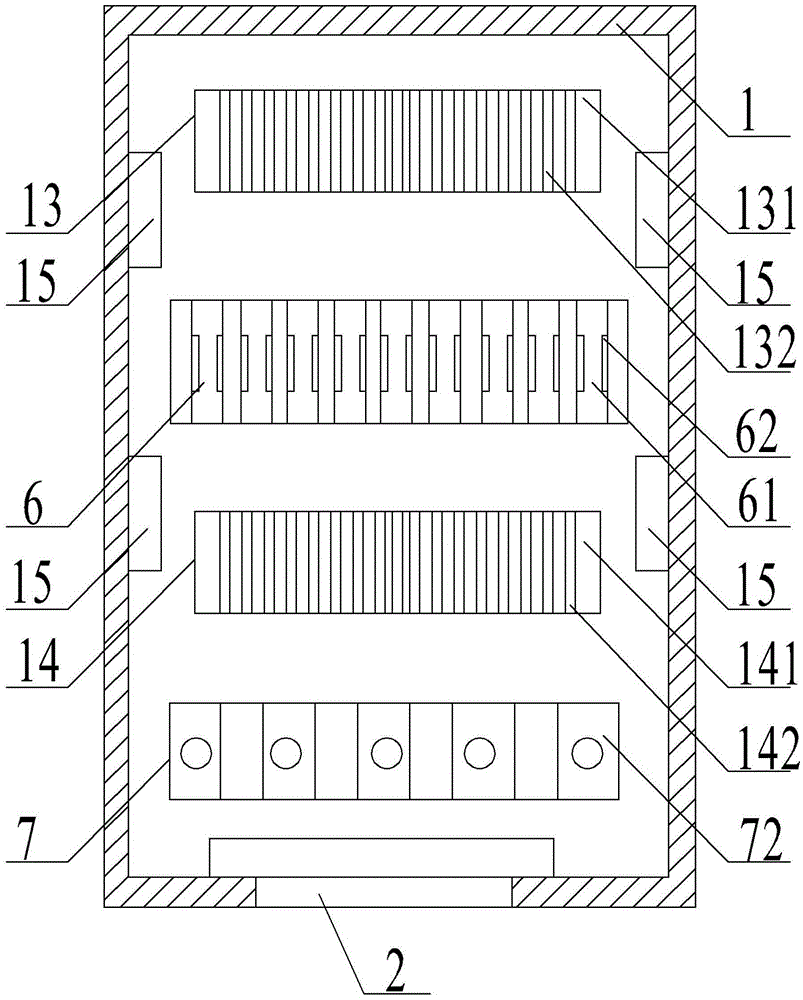

[0021] Attached below Figure 1-8 The invention is described in further detail with specific embodiments:

[0022] An optical cable connection distribution box, comprising a box body 1, a box door 5 arranged on the front of the box body 1, an upper cable management frame 13 arranged in the box body 1 from top to bottom, a tap frame 6, and a lower cable management box Frame 14 and surplus thread frame 7, be arranged on box body 1 side wall 11 and be used for digging out connection hole 2 and side fixing frame 15 of optical cable 8 and be used for blocking up the plugging mechanism that digs out connection hole 2;

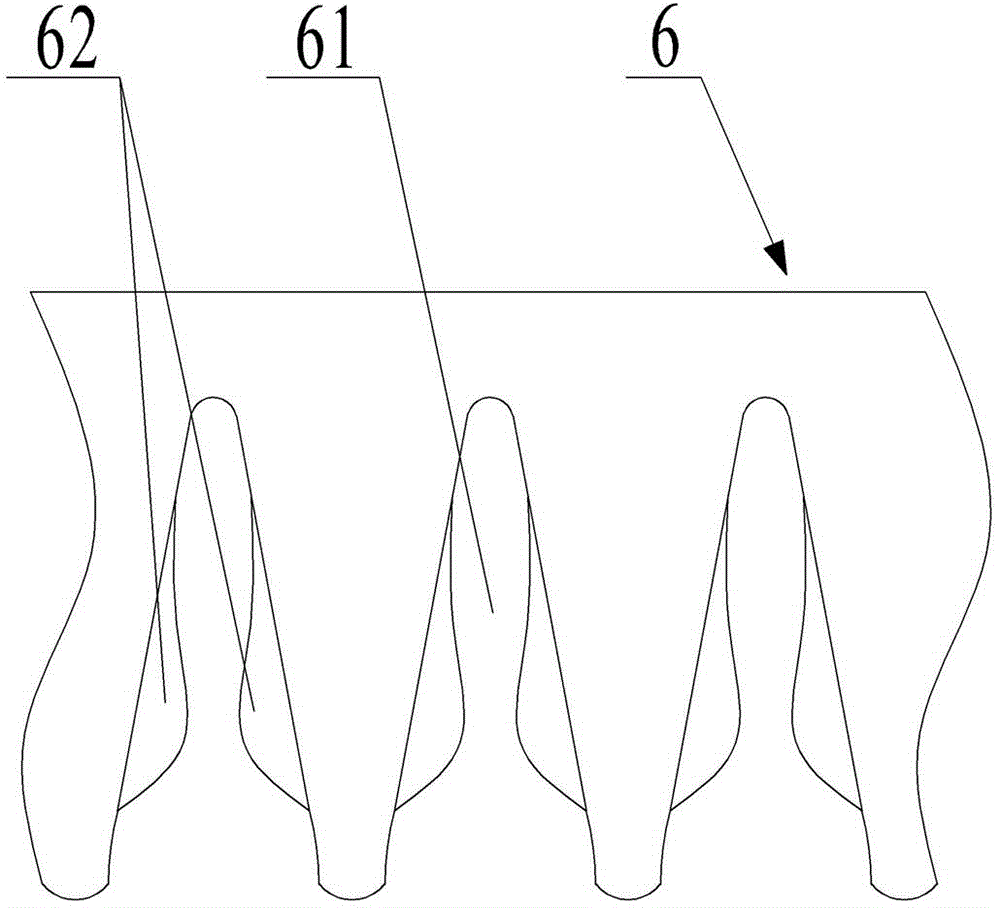

[0023] The upper wire management frame 13 is composed of the upper wire management teeth 131 and the upper wire management groove 132 formed by the adjacent upper wire management teeth 131; The snap springs 62 on the inner sidewalls of the shape card slot 61 are formed; the lower wire management frame 14 is composed of the lower wire management groove 142 formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com