LCD light leakage detection mechanism

A light leakage detection and adjustment mechanism technology, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as inconvenient operation, low work efficiency, and influence on production efficiency, so as to improve the stability of rotation, smooth up and down movement, and prevent wires winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

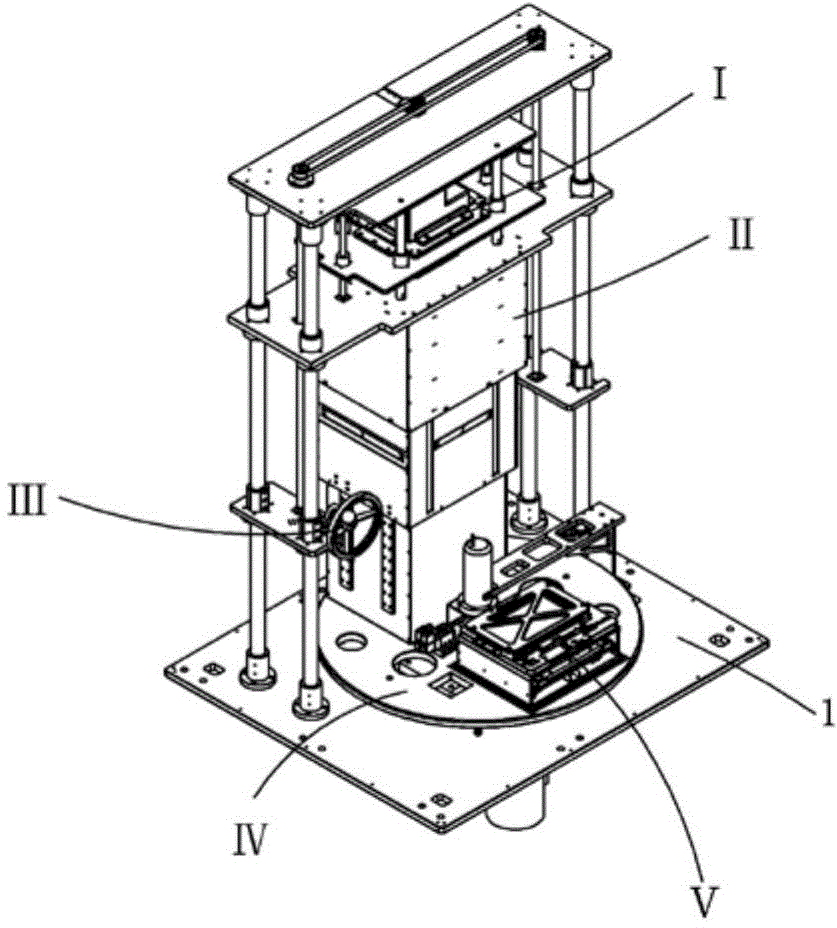

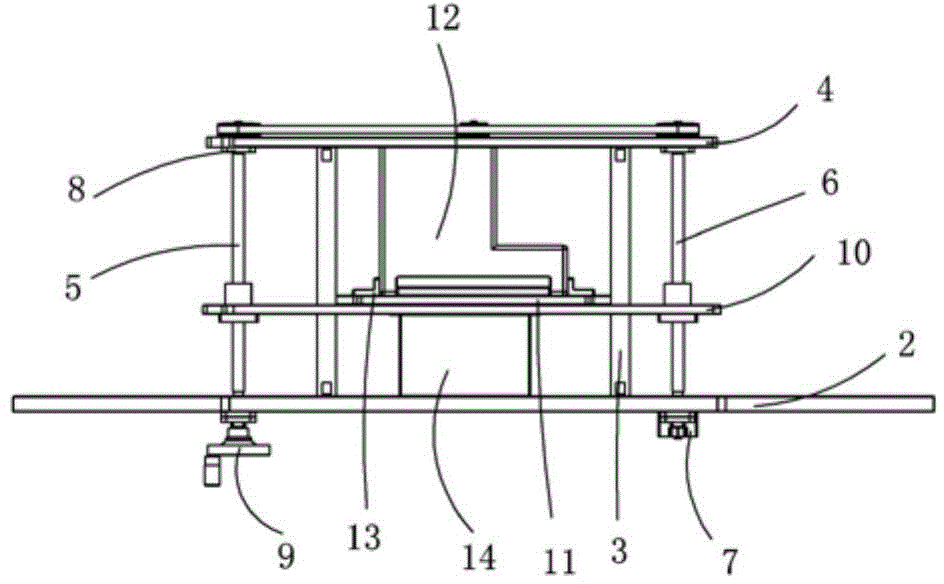

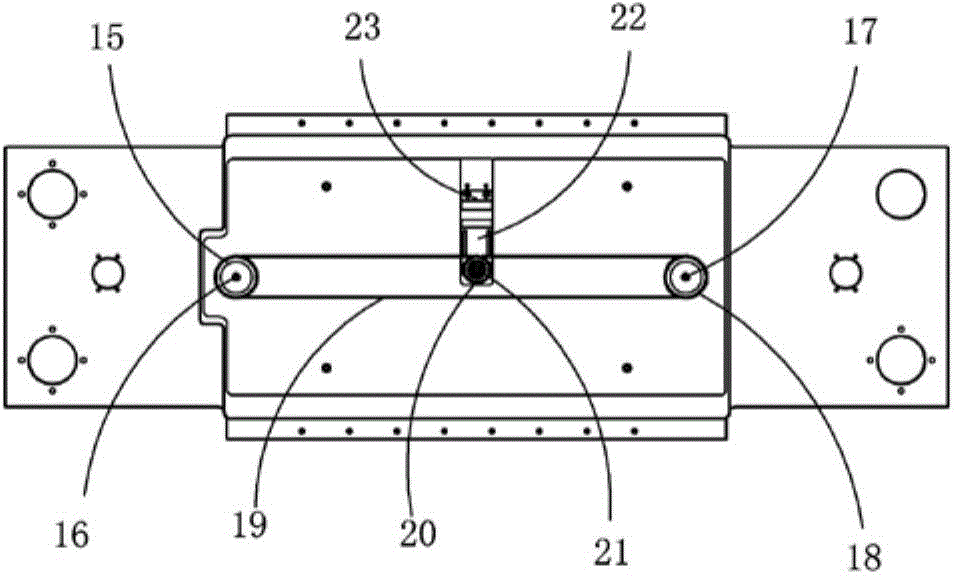

[0045] example, see attached Figures 1 to 15 , an LCD light leakage detection mechanism, which includes a base plate 1, a CCD adjustment mechanism I, a sealed box mechanism II, a lift adjustment mechanism III, a turntable mechanism IV and a carrier device V, and the lift adjustment mechanism is installed on the upper part of the base plate; the turntable The mechanism is installed on the base plate, and the carrier device is installed on the turntable mechanism; the connection between the CCD adjustment mechanism and the lift adjustment mechanism is to use the CCD of the CCD adjustment mechanism to support the base plate and the nuts on the left and right screw rods of the lift adjustment mechanism The CCD adjustment mechanism and the sealing box mechanism are connected together by using the CCD supporting bottom plate of the CCD adjustment mechanism and the upper sealing box of the sealing box mechanism to be fixedly connected together through four reinforcing ribs. The CCD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com