Nano silver conductive film and touch panel adopting same

A conductive film and nano-silver technology, applied in nanotechnology, nanotechnology, conductive layers on insulating carriers, etc., can solve problems such as visual differences and haze differences, and achieve the effect of reducing haze differences and consistent visual effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

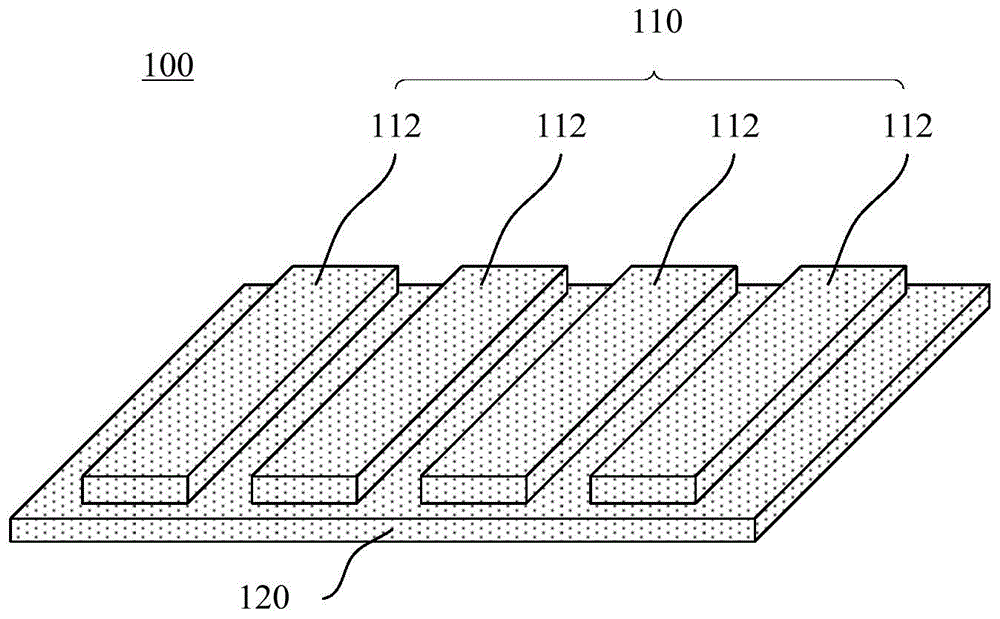

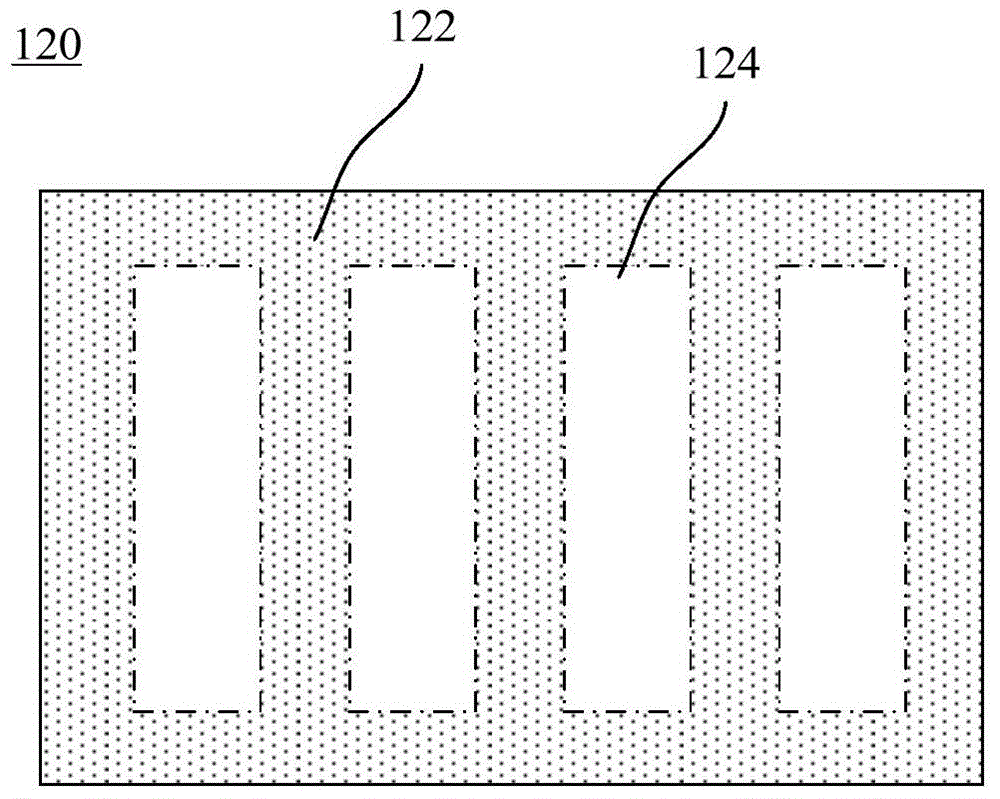

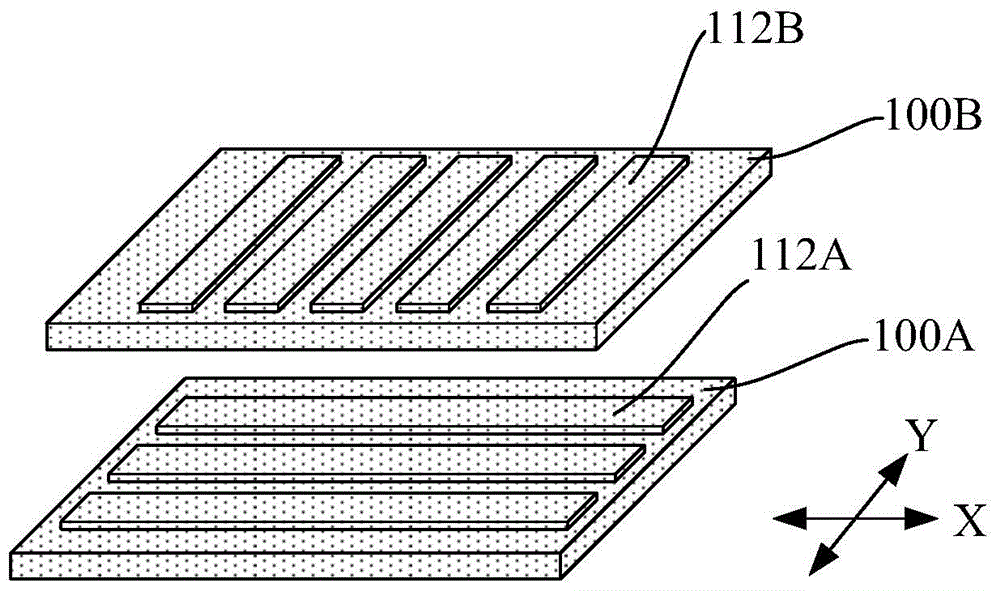

[0030] In order to compensate for the visual difference caused by the use of nano-silver electrodes, the invention performs haze compensation on the electrode gap of the nano-silver conductive film to reduce the haze difference and achieve good visual effects. A component capable of providing haze compensation is referred to as a haze compensation component in the present invention, and the haze of the haze compensation area is equivalent to that of the nano-silver electrode. "Equivalent" in the present invention can be understood as being completely the same, not exactly the same but with little difference in value (for example, the haze difference is not greater than 0.2, or other reasonable differences). The difference is either imperceptible or difficult to discern. Therefore, the overall haze of the nano-silver conductive film is uniform. Because the haze value of the nano-silver electrode of the commonly used nano-silver conductive film is as large as 1.0-2.8, the overa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| haze | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com