X-ray tube heat dissipation device

A technology for X-ray tubes and cooling devices, which is applied to parts of X-ray tubes, etc., can solve problems such as X-ray tube burnout, X-ray tube damage, and waste of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments described below are exemplary, and are only for explaining the present invention, and should not be construed as limiting the present invention.

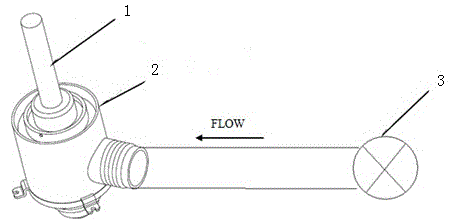

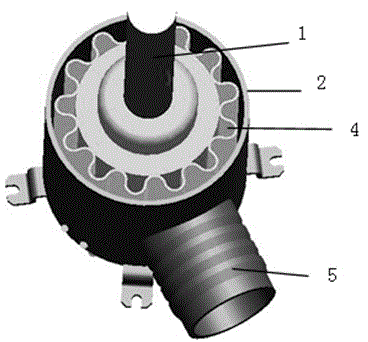

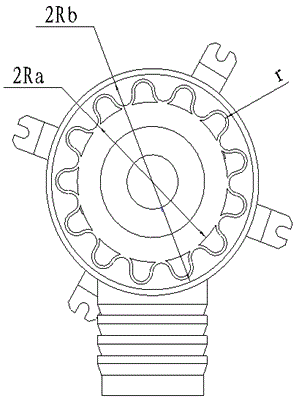

[0027] The X-ray tube cooling device of the present invention will be described below with reference to the accompanying drawings, wherein figure 1 is a schematic diagram of an embodiment of the present invention; figure 2 is a schematic diagram of an embodiment of the heat dissipation component of the present invention, image 3 Yes figure 2 The schematic top view of the embodiment.

[0028] According to an embodiment of the present invention, such as figure 1 , 2 , Shown in 3, the X-ray tube cooling device provided by the present invention comprises:

[0029] X-ray tube 1;

[0030] Cylindrical air guide 2, the X-ray tube 1 is installed at the center of the cylindrical air guide 2, the central axis of the X-ray tube 1 coincides with the central axis of the cylindrical air guide 2;

[0031] A heat dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com