Terminal structure of secondary battery and secondary battery

A terminal structure and secondary battery technology, applied in secondary batteries, small-sized batteries/battery packs, structural parts, etc., can solve the problem of large-scale non-aqueous electrolyte secondary batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

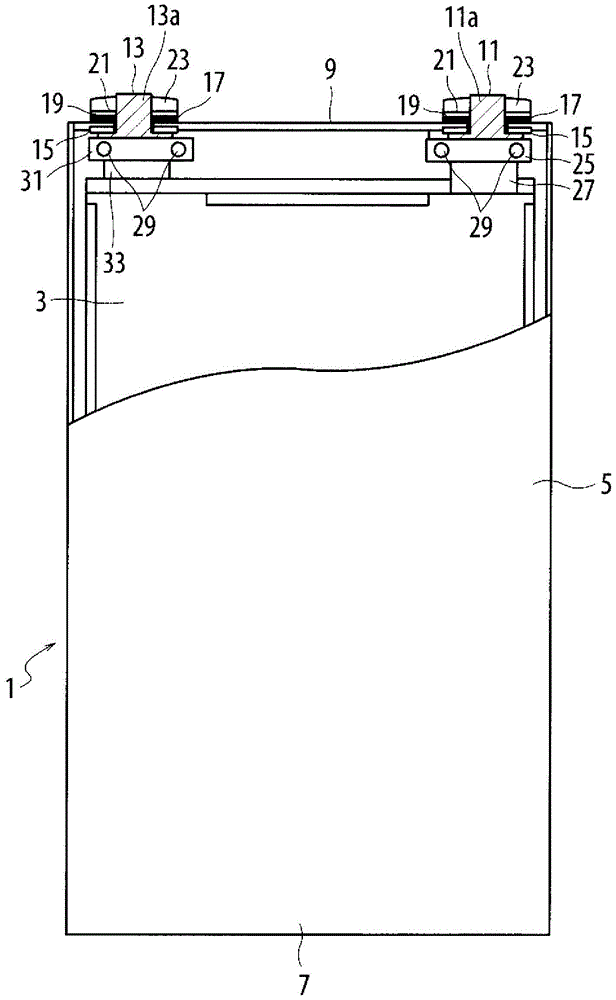

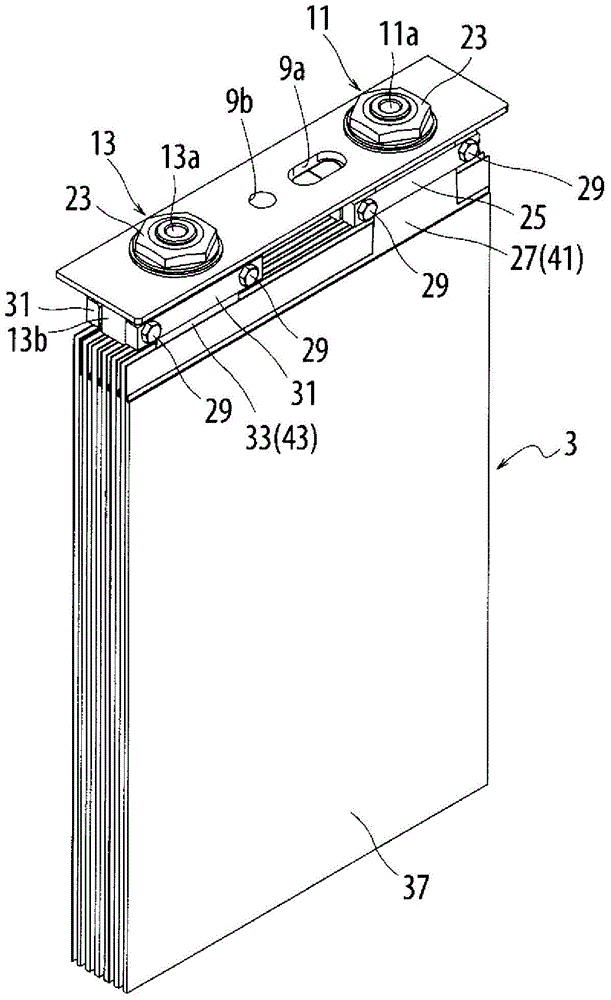

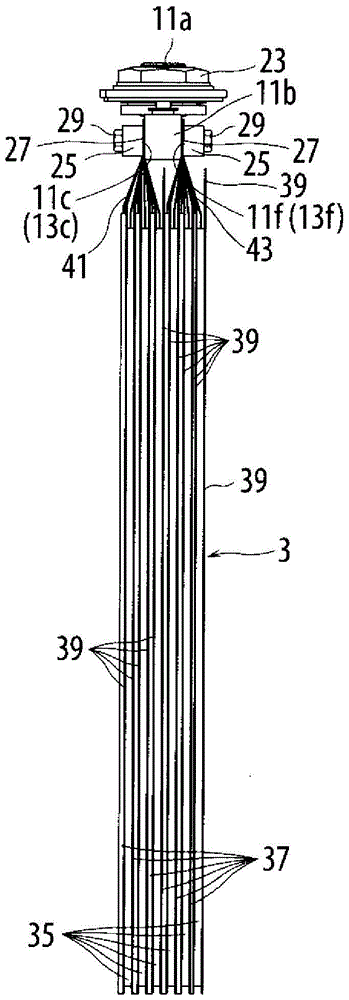

[0034] Hereinafter, the structure of the embodiment of the terminal structure and the secondary battery of the present invention will be described in detail with reference to the drawings. figure 1It is a partial cross-sectional front view of a lithium ion secondary battery 1 as a nonaqueous electrolyte secondary battery to which the terminal structure of the first embodiment of the present invention is applied. However, in this embodiment, in order to facilitate understanding, the thickness dimensions of some members are exaggeratedly drawn, and the number of pairs and pole plates is also smaller than the actual number.

[0035] Such as figure 1 As shown, the lithium ion secondary battery 1 of the present embodiment includes an electrode plate group 3 and a rectangular battery container 5 made of stainless steel that accommodates the electrode plate group 3 therein. The battery container 5 includes a battery can 7 with one end open and a battery cover 9 , and after the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com