Part cleaning device

A technology for cleaning devices and parts, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of poor cleaning effect, inability to control the temperature of cleaning liquid well, and low cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

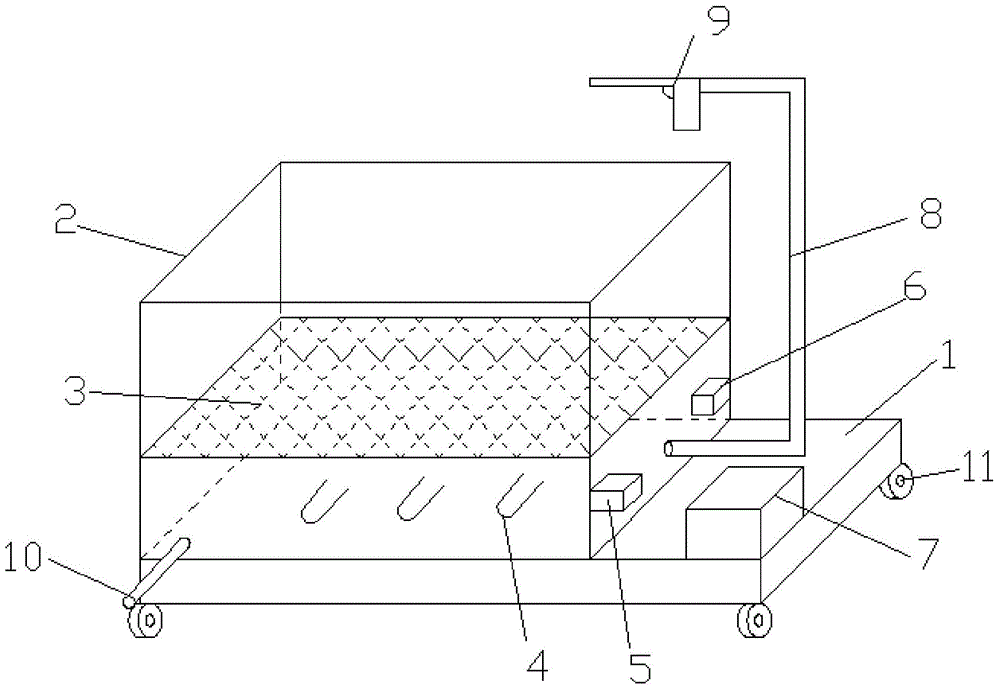

[0024] figure 1 The parts cleaning device shown includes a bottom plate 1, a cleaning container 2 and a control box 7 are arranged on the bottom plate 1, a filter plate 3 is arranged in the cleaning container 2, and a heating device 4, an ultrasonic generator 5, and a temperature sensor 6 are arranged below the filter plate 3. The heating device 4, the ultrasonic generating device 5, and the temperature sensor 6 are respectively connected to the control box 7, and the bottom of the cleaning container 2 is connected to the circulation pipe 8, and the other end of the circulation pipe 8 is connected to the spray device 9, and the lower end of the cleaning container 2 is provided with a water outlet pipe 10. Rollers 11 are arranged at the bottom of the bottom plate 1 .

[0025] The heating device 4 is several heating pipes.

[0026] A filter screen is arranged at the port of the circulation pipe 8 .

[0027] The circulation pipe 8 is a hose.

[0028] The spraying device 9 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com