Personal protective equipment hinging shaft protecting shell forming device

A technology of forming device and hinge shaft, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of large workpiece size, difficult to process with ordinary equipment, no such workpiece processing equipment, etc., and achieves convenient processing and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

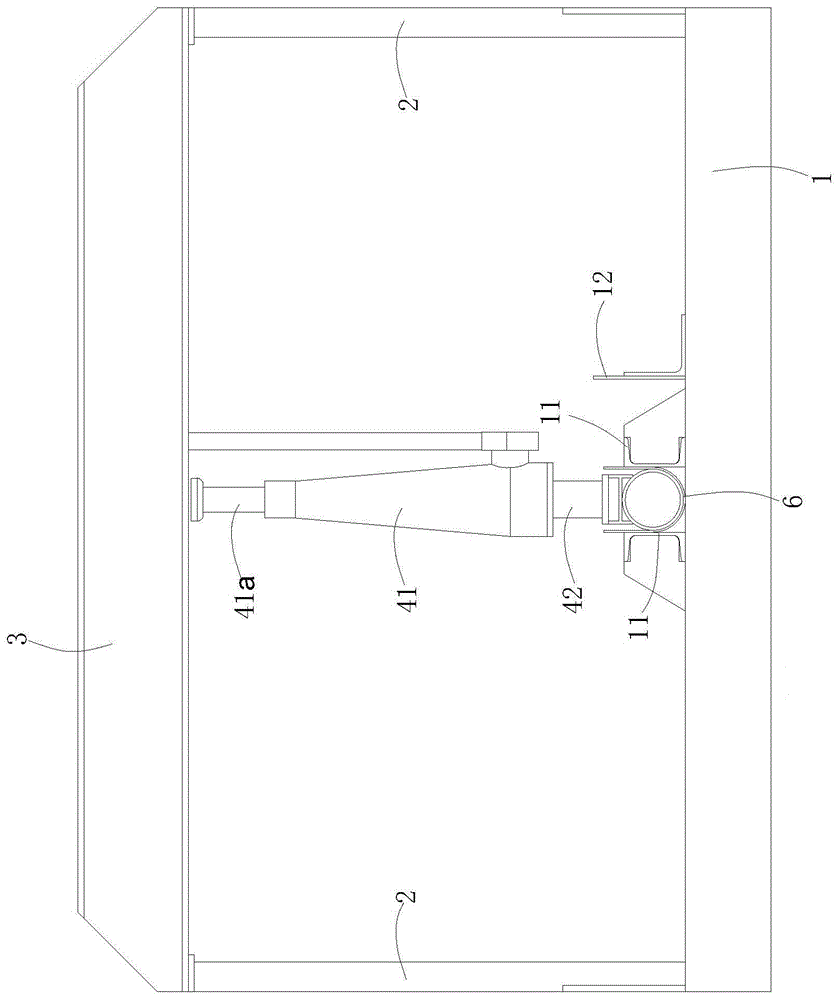

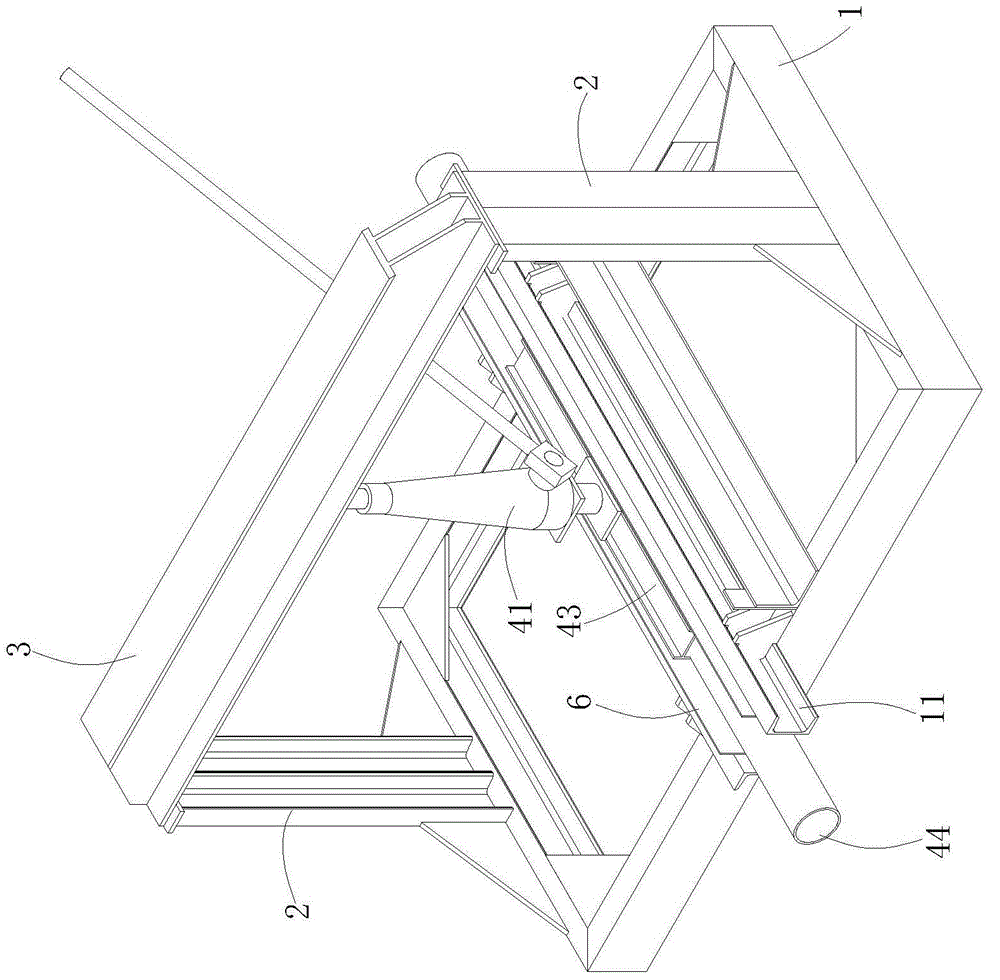

[0016] Such as Figures 1 to 4 shown

[0017] The device includes a base 1, two support rods 2, a beam 3 and a pressing assembly.

[0018] The base 1 is generally a rectangular frame structure. Two channel steels 11 are vertically welded on the upper end of the base 1 so that the openings of the two channel steels 11 are correspondingly outward. The side walls of the two channel steels 11 and the upper end of the base 1 are jointly formed Pressure groove 5, two limit baffles 12 are welded on the base 1; two vertical support rods 2 are welded on the base 1, and the two support rods 2 are distributed on both sides of the length direction of the pressing block, and the horizontal beam 3 The two ends are welded on the upper ends of the two support rods 2 .

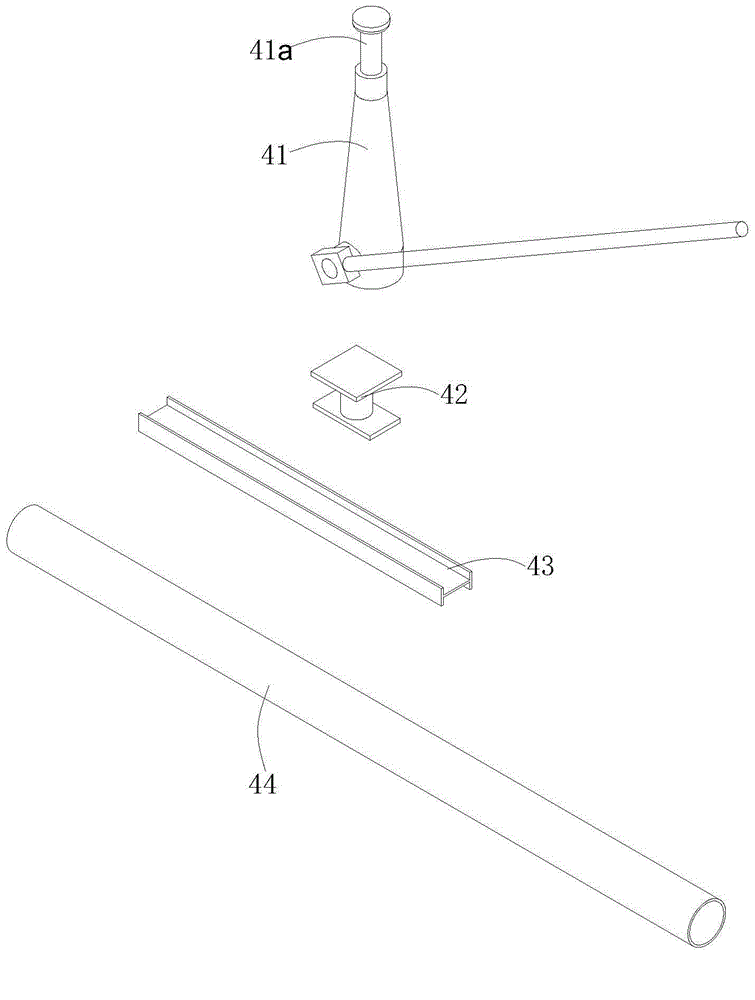

[0019] The pressing assembly includes a jack 41, a fixed block 42, a pressure bar 43 and a mandrel 44 matched with the pressure groove 5. The mandrel 44 is cylindrical, the upper end of the fixed block 42 matches the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com