Large-hole diameter multifunctional precise multi-claw synchronous clamp

A multi-functional, large-aperture technology, used in the manufacture of tools, tool holder accessories, chucks, etc., can solve the problem that the large-size four-jaw single-action chuck cannot guarantee the machining accuracy, and the self-centering chuck lacks the processing range and processing. Accuracy, low processing efficiency and other problems, to achieve the effect of compact structure, reduce labor intensity, and meet processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

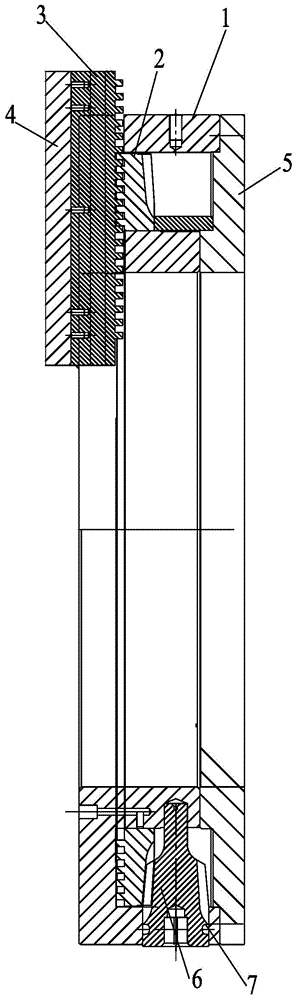

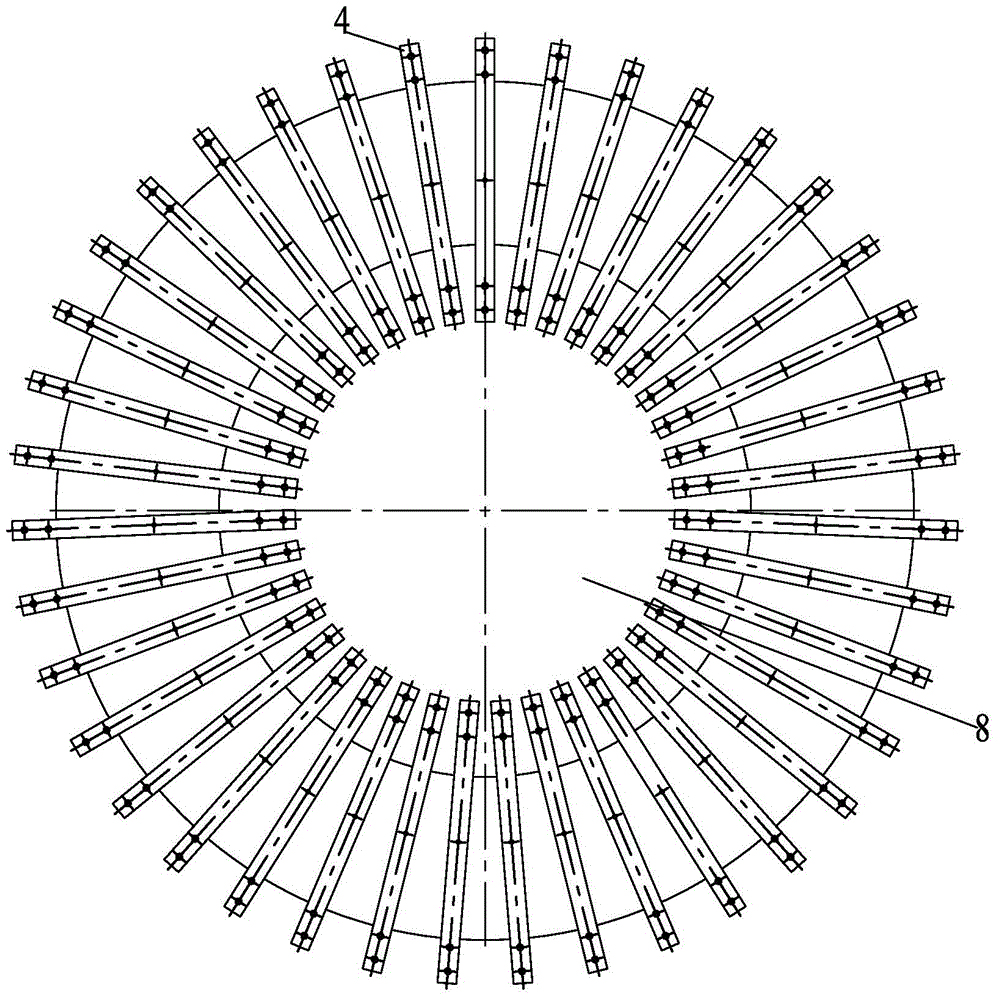

[0015] Such as figure 1 and figure 2 Shown: in order to ensure machining accuracy, high machining efficiency, and meet the processing needs of large-scale tubes, discs, and rods, the present invention includes a disc body 1, and a central part of the disc body 1 is provided with a The large through hole 8 is provided with a plurality of uniformly distributed claws 4 on the outer ring of the large through hole 8; a claw movement drive mechanism for driving the claws 4 to move synchronously is arranged in the disc body 1 .

[0016] Specifically, the large through hole 8 on the disc body 1 can meet the processing requirements of pipes. The claws 4 are located above the disc body 1 and evenly distributed on the outer ring of the large through hole 8. The inner diameter of the large through hole 8 can be 620 mm. The claw motion drive mechanism can drive the synch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com