Large-specification multi-jaw precise self-centring chuck

A self-centering chuck, large-scale technology, applied in the direction of turning equipment, tool holder accessories, metal processing equipment, etc., can solve the lack of processing range and processing accuracy of self-centering chuck, can not guarantee processing accuracy, processing efficiency Low and other problems, to achieve the effect of compact structure, reduce labor intensity, and meet processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiments in the drawings:

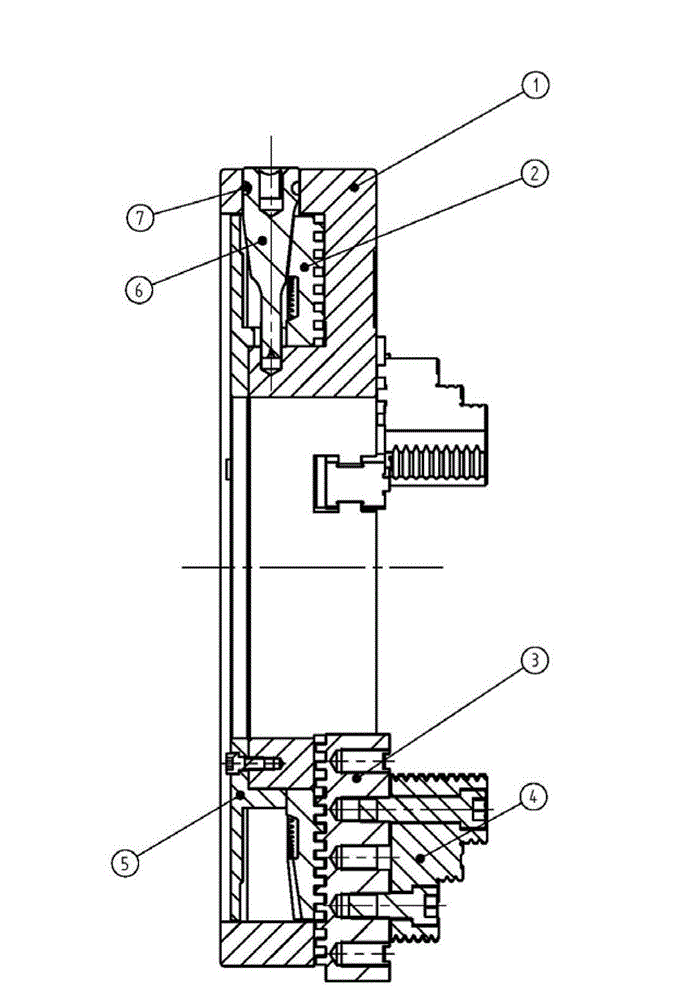

[0010] Such as figure 1 As shown, it includes a disc body 1, a coil wire 2, a sliding seat 3, a claw 4, a gland 5, a bevel gear 6 and a pin 7.

[0011] The plate body 1 is provided with three straight grooves, three claws 4, three sliding seats 3, a coil 2, three bevel gears 6, a gland 5 and three pins 7. The three jaws 4 are respectively connected with the three sliding seats 3 through the sliding seat I-shaped groove. The bottom of the sliding seat 3 is provided with a flat thread, and the flat thread engages with the corresponding flat thread of the coil 2, and the coil 2 is inserted in the The inner cavity of the disc body 1 is fixed by the gland 5, the three bevel gears 6 are positioned and installed on the side of the disc body 1 by three pins 7 respectively, and the bevel gear 6 keeps meshing with the corresponding tooth surface on the disc wire 2. The three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com