Method for compensating motion path of mechanical arm based on vision measurement

A compensation method and motion path technology, applied in manipulators, manufacturing tools, etc., can solve problems such as bruises or scratches on spacecraft products, difficult installation work, and small installation space, so as to achieve safer and more reliable motion, solve assembly problems, High safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The method for compensating the motion path of the manipulator based on vision measurement of the present invention will be further described below in conjunction with the accompanying drawings. This description is only exemplary and not intended to limit the protection scope of the present invention.

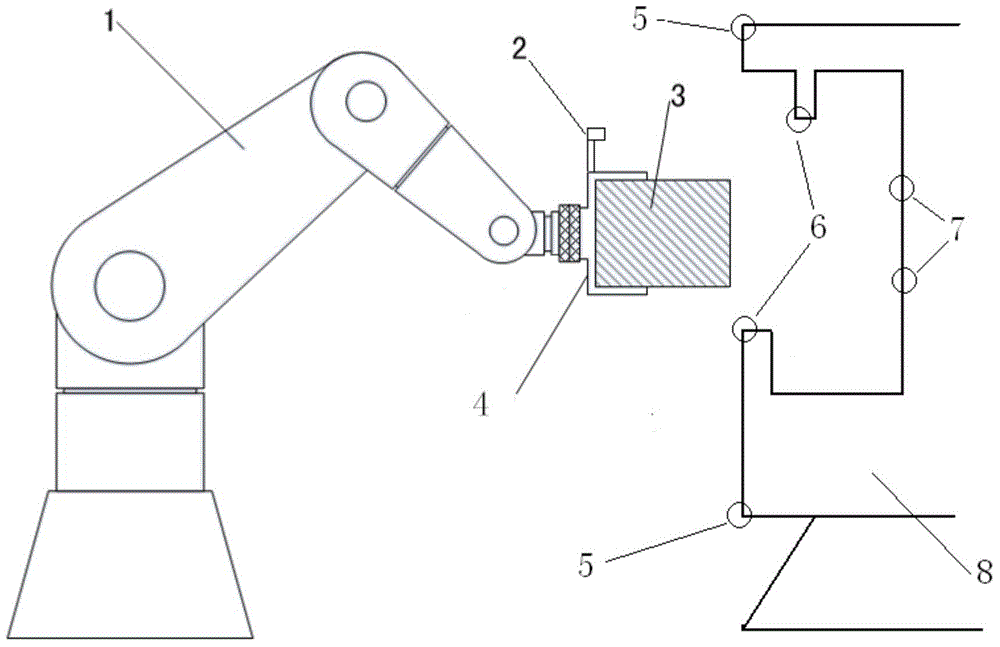

[0038] see figure 1 , figure 1 It shows the operation process of applying the robotic arm based on vision measurement of the present invention to the assembly of spacecraft, wherein the binocular vision sensor 2 is installed on the end effector 4 of the robotic arm 1, and the workpiece 3 to be assembled is clamped by the end effector 4, The target assembly position of the workpiece 3 to be assembled is at the characteristic point 7 of the internal target assembly position of the spacecraft 8 , and the mechanical arm 1 must go deep into the interior of the spacecraft 8 along the way and avoid collision with the protrusion 6 of the spacecraft. The feature points 5 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com