Case-hardened steel and carburized material

A technology of hardening steel and carburizing, applied in chemical instruments and methods, metal material coating process, coating, etc., can solve problems such as gear load increase, and achieve the effect of excellent fatigue resistance and excellent cold forgeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

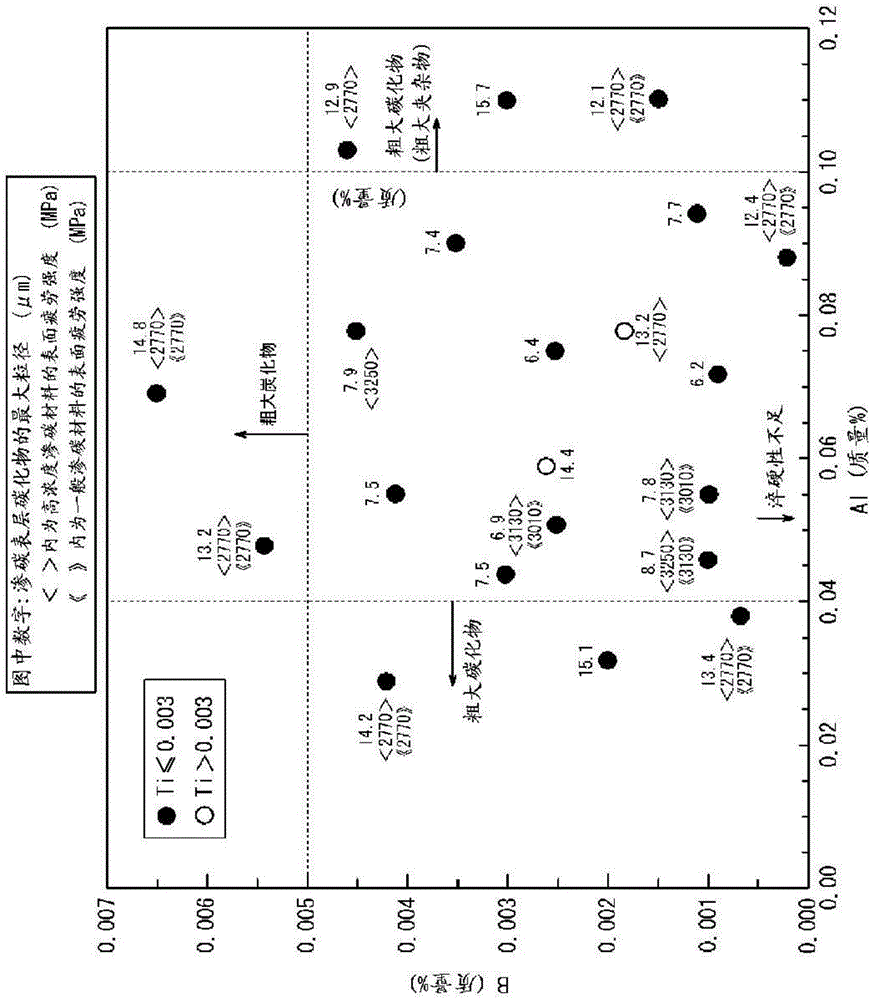

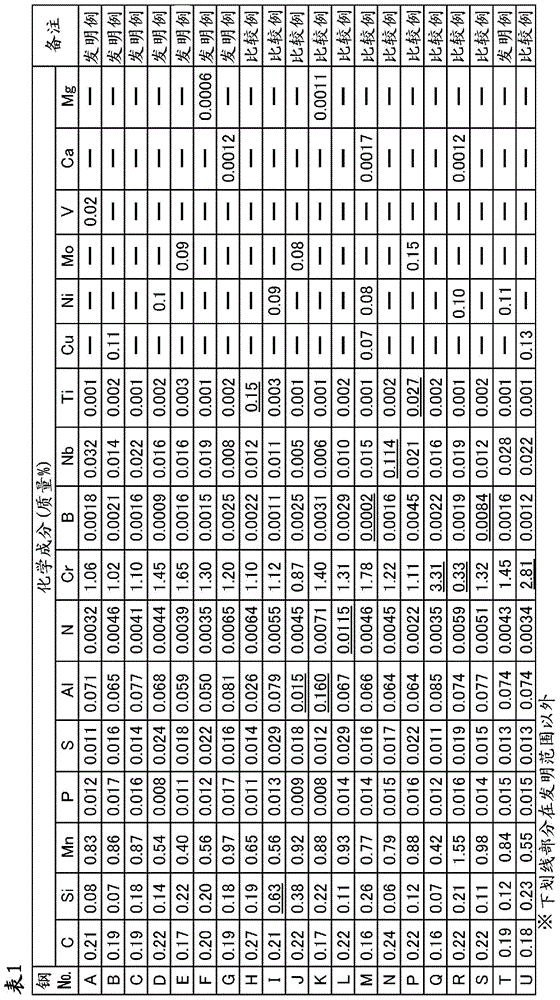

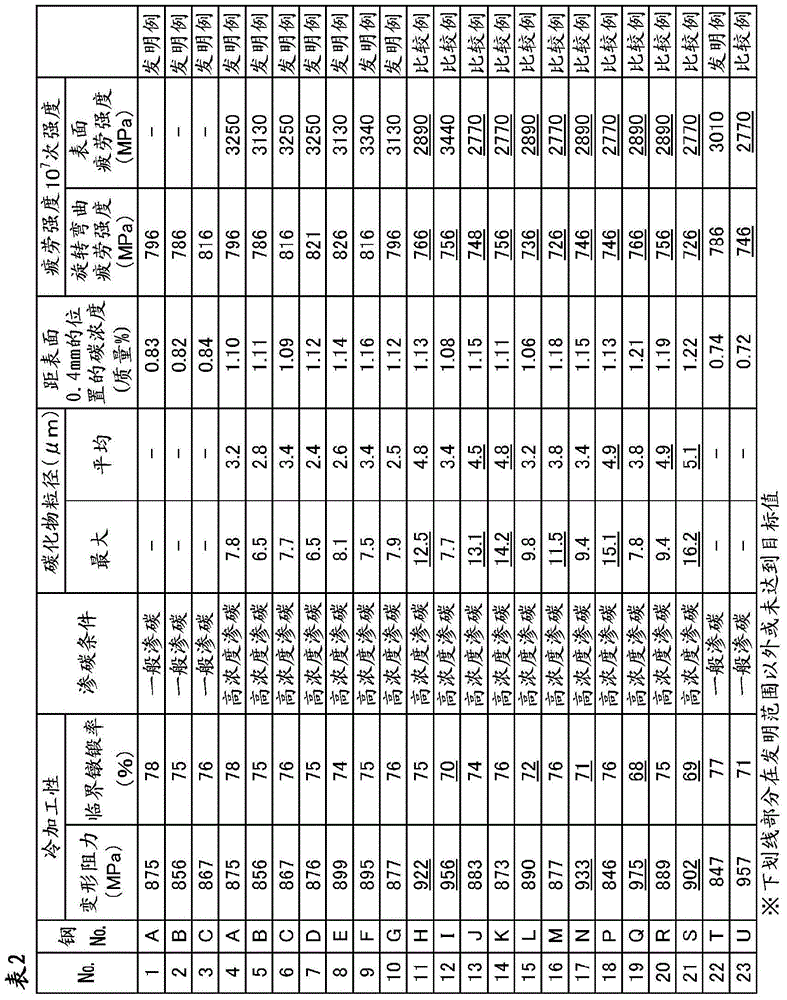

[0084] Next, examples of the present invention will be described.

[0085] Melt the steel with the composition shown in Table 1 (the balance is iron and unavoidable impurities), heat it temporarily to above 1150°C, and then turn it into an intermediate billet with a square cross-section of 170mm×170mm, and then heat it to Ac3+100°C or above After that, it is formed into a round bar with a diameter of 60 mm by hot rolling. The cold forgeability of the obtained round bar was evaluated.

[0086] Table 1

[0087]

[0088] Here, cold workability was evaluated using two items of critical upset rate and deformation resistance.

[0089] That is, a test piece with a diameter of 10mm and a height of 15mm is collected from a position whose depth is 1 / 4 diameter (1 / 4D position) from the surface of the bar steel, and a 300t press is used to measure the compressive load during 60% upset forging, Calculated using the method of measuring deformation resistance using end-face limited com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com