Split crevice cover structure of fire door

A fire door, split-type technology, applied in the field of fire doors, can solve the problems of inconvenient assembly of fire doors, inability to prevent the spread of fire, and the spread of smoke, and achieve the effect of preventing the spread of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

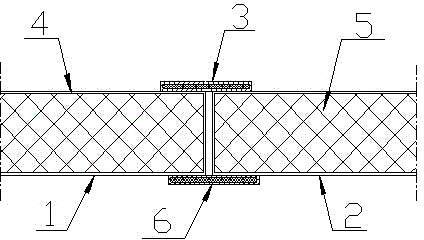

[0016] Embodiment 1: see figure 1 , a split-type fire door cover seam structure, including a door frame and a door leaf, the door leaf includes a left door leaf 1 and a right door leaf 2. Both the left door leaf 1 and the right door leaf 2 are composed of a frame body 4 and an inorganic fireproof core material board 5 inside the frame body 4. The frame body 4 is stamped and formed by a metal composite board, and the metal composite board includes two metal plates and a The adhesive between two metal plates and bonding the two metal plates together, in specific implementation, the metal plate is made of stainless steel plate, which has better stability.

[0017] On the left door leaf 1 and the right door leaf 2, a cover seam plate 3 is respectively closely attached, and the two cover seam plates 3 are respectively located on the inside and outside of the door leaf. The gap between the door leaf 1 and the right door leaf 2 is closed. The cover seam plate 3 is in-line, and is f...

Embodiment 2

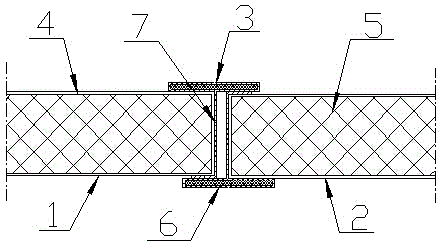

[0020] Example 2, see figure 2 The difference from the implementation of your 1 is that a connection plate 7 is provided on the opposite sides of the two cover seam plates 3, so that the overall section formed by the cover seam plate 3 and the connection plate 7 is T-shaped, and the two connection plates 7 are far away from the cover. One side of the slit plate 3 is bent in a direction away from each other, and the two cover slit plates 3 are respectively fastened together with the left door leaf 1 and the right door leaf 2 through the connecting plate 7, and the adjacent end faces of the left door leaf 1 and the right door leaf 2 are fixed together. Covering: it can better protect the adjacent sides of the left door leaf 1 and the right door leaf 2, so that the cover seam plate 3 can stably seal the gap between the left door leaf 1 and the right door leaf 2, so as to prevent the spread of fire and smoke diffusion. When the door leaf was closed, the cover seam plate 3 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com