Water-stopping method for the contact part between shield segment and cast-in-place concrete

A technology of shield segments and contact parts, which is used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of unsuitable shield segment water-stop construction, impossibility of pre-embedding water-stop components, etc., and achieves convenient construction. , good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

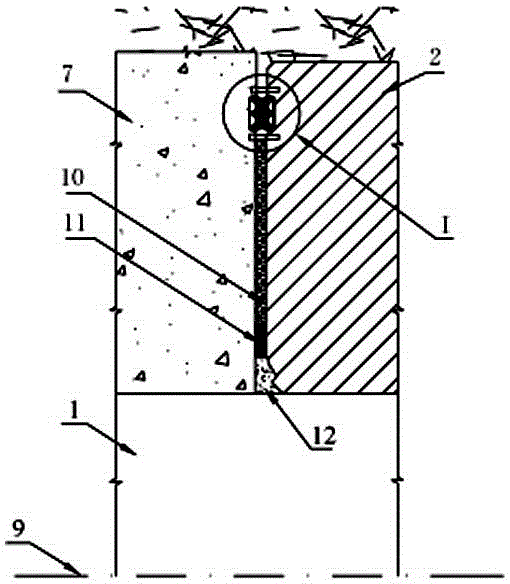

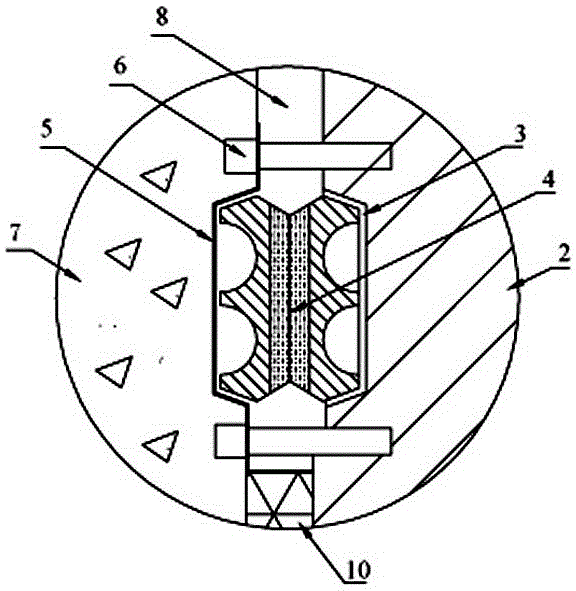

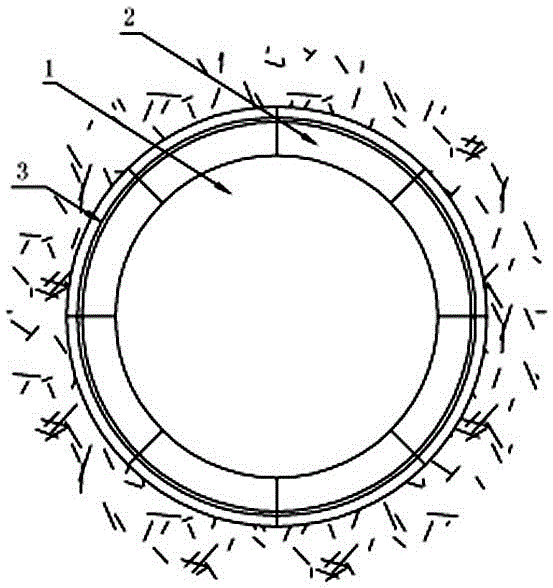

[0013] Such as Figure 1-3 As shown, the water-stopping method of the shield segment of the present invention and the contact position of cast-in-situ concrete is carried out according to the following steps:

[0014] Step 1: After the tunnel 1 shield excavation is completed, after the lining of the shield segment 2 is stabilized, a rubber water stop ring 4 is placed in the annular water stop groove 3 on the end face of the shield segment 1, and then the concave steel Sheet 5 and expansion bolt 6 fix and press the rubber water stop ring 4 in the annular water stop groove 3 on the end surface of the shield segment 2 to ensure that the rubber water stop ring 4 is fully compacted;

[0015] The second step is to pour the cast-in-place concrete lining 7 of the tunnel 1. During the pouring process, a joint 8 with a width of 10mm is reserved between the cast-in-place concrete lining 7 and the end face of the shield segment 2 along the radial direction of the tunnel 1;

[0016] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com