Automatic assembly device for plane thrust retainer and assembly method for automatic assembly device

A cage and thrust technology, applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low one-time pass rate, low degree of automation, high cost, etc., achieve high one-time pass rate of products, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the drawings in the specification:

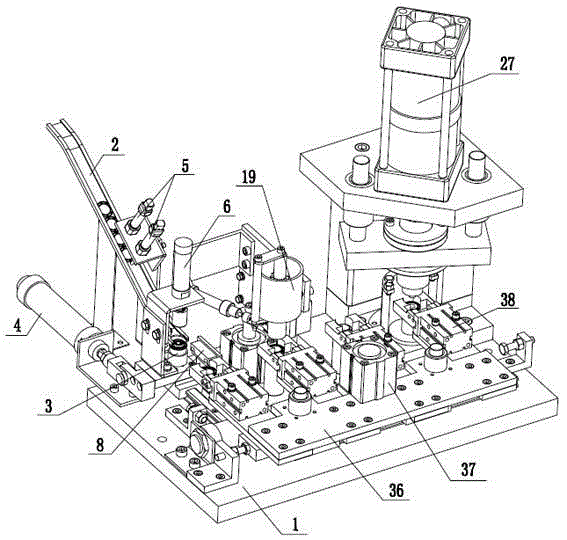

[0026] An automatic assembling device for a plane thrust cage includes a base 1, on which a feeding positioning device, a clamping and shifting device, an automatic ball assembly device and a riveting device are arranged.

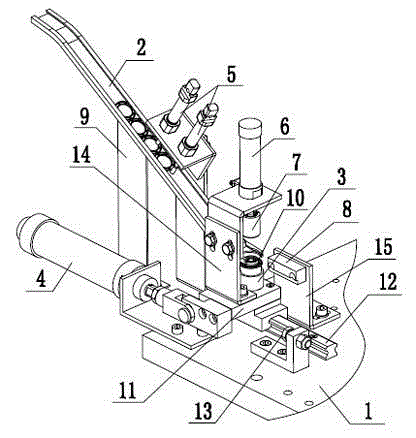

[0027] The feeding and positioning device includes a forehearth 2, a feeding seat 3, a feeding cylinder 4, two workpiece release cylinders 5, a compression cylinder 6, a pressing sleeve 7 and a positioning rubber 8. The forehearth 2 is fixed to the base 1 by a forehearth support 9 On the upper, the material channel 2 holds the cage, and the discharge port of the material channel 2 is provided with an upper material seat 3, which matches the shape of the retainer; the upper material seat 3 is provided with a guide nail with a spring at the bottom 10. The feeding seat 3 is set on the sliding seat 11, and a slide rail 12 is provided under the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com