Three-way valve

A three-way valve and valve body technology, applied in the field of three-way valves, can solve the problems of easy wear, increased production cost, and short service life of the three-way valve, so as to prolong the service life, save the production cost, and overcome the short service life of the valve core. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

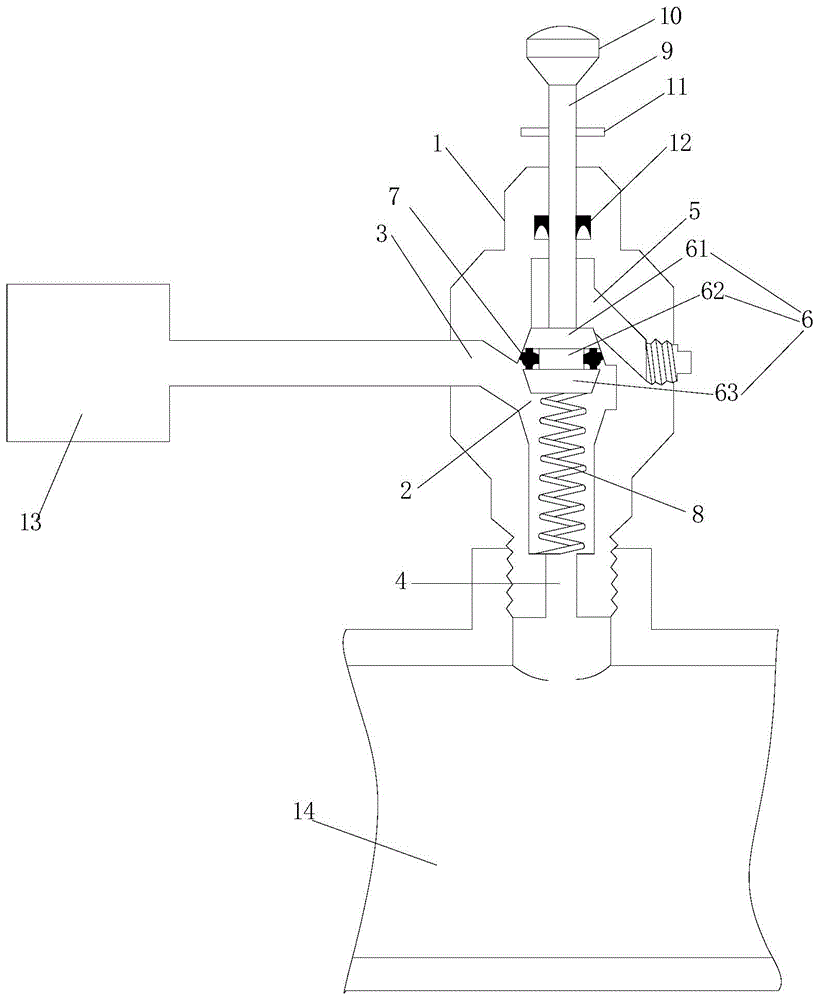

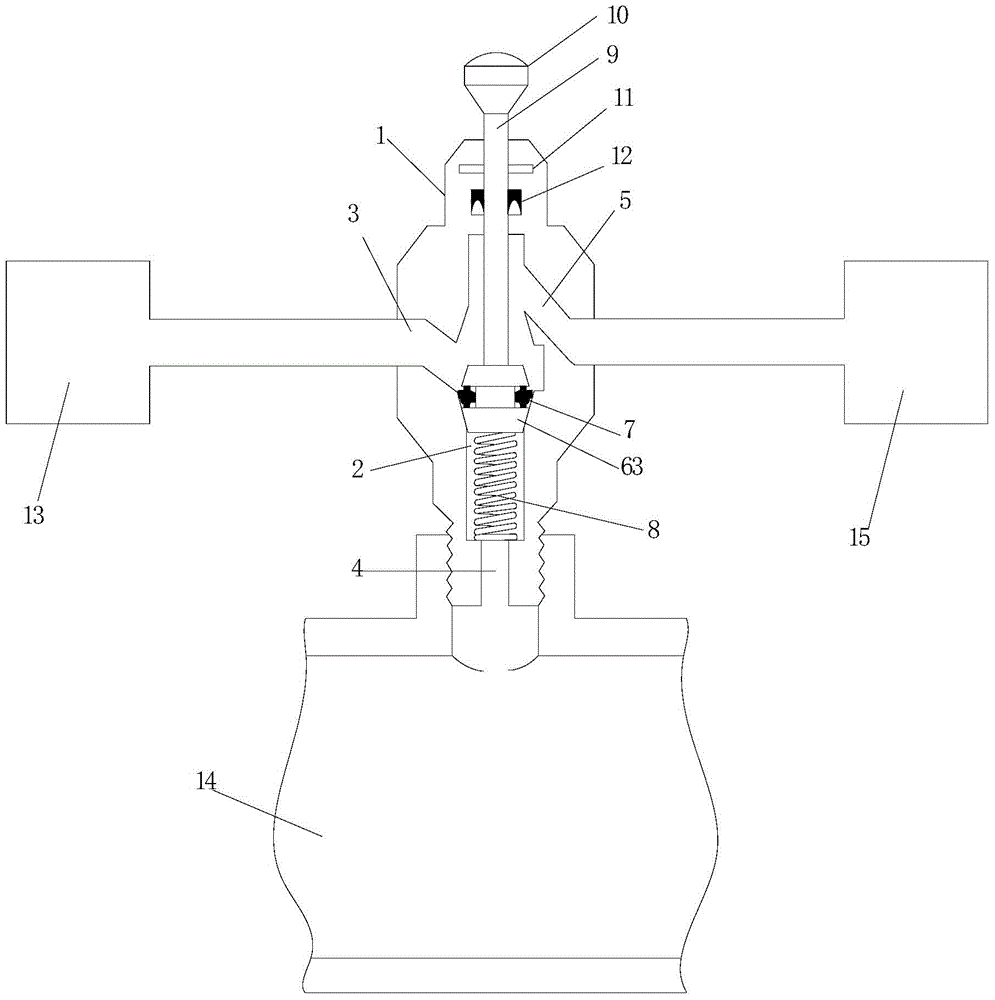

[0010] Such as figure 1 and figure 2 As shown, the three-way valve of the present invention includes a valve body 1. The valve body 1 may be integrated, and may also include an upper end cover and a lower end cover connected with the valve body. There is a cavity 2 inside the valve body 1, and a first channel 3, a second channel 4, and a third channel 5 communicating with the cavity 2 respectively. The first channel 3 is connected to a safety device 13 (SAV or SBV), and the second channel The channel 4 communicates with the pressure chamber 14, and the third channel 5 is connected with the pressure testing device 15. A valve core 6 is arranged in the cavity 2, and the valve core 6 includes an upper trapezoidal body 61, a cylinder 62, and a lower trapezoidal body 63. The lower end of the valve core 6 is A spring 7 is connected with the lower end of the valve body 1 . The periphery of the cylinder 62 is provided with a sealing ring 8, the upper surface of the valve core 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com