Automatic alignment parallel seal welding method for microelectronic packaging in high vacuum state

A technology of microelectronic packaging and parallel sealing and welding, which is used in microstructure devices, manufacturing microstructure devices, decorative arts, etc., to achieve the effects of improving weld quality, saving investment costs, and accurate and automatic alignment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

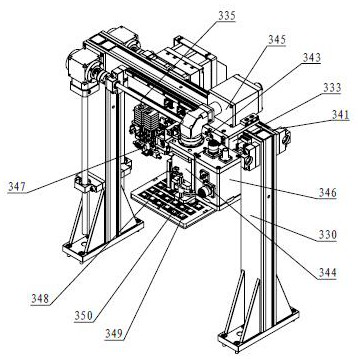

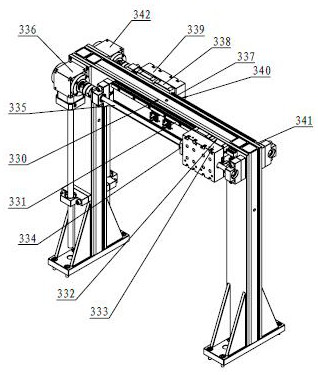

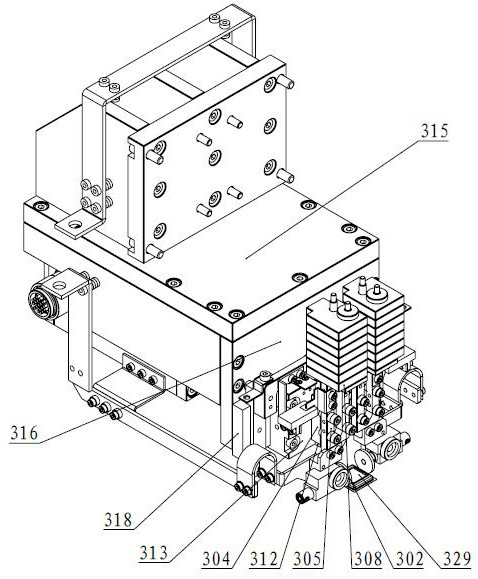

[0025] The present invention is described in detail below in conjunction with accompanying drawing:

[0026] An automatic alignment parallel sealing and welding mechanism for microelectronic packaging in a high vacuum state, including a high vacuum sealed welding chamber, a welding mechanism traveling gantry 330 is arranged in the high vacuum sealed welding chamber, and the welding mechanism travels in front of the beam of the gantry 330 On the side, there is horizontally provided with an alignment grab cover plate traversing guide rail 331, and a grab mechanism installation slider 332 is movably arranged on the alignment grab cover plate traverse guide rail 331, which is connected to the grip mechanism installation slider 332. There is a catch alignment nut connection block 333, and the catch alignment nut connection block 333 is screwed together with the grab alignment nut 334 and the grab horizontal alignment lead screw 335, and one end of the grab horizontal alignment lead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com