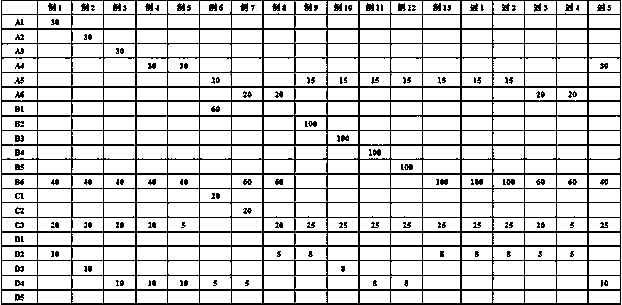

Patents

Literature

31results about How to "Overcome the shortcoming of short life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

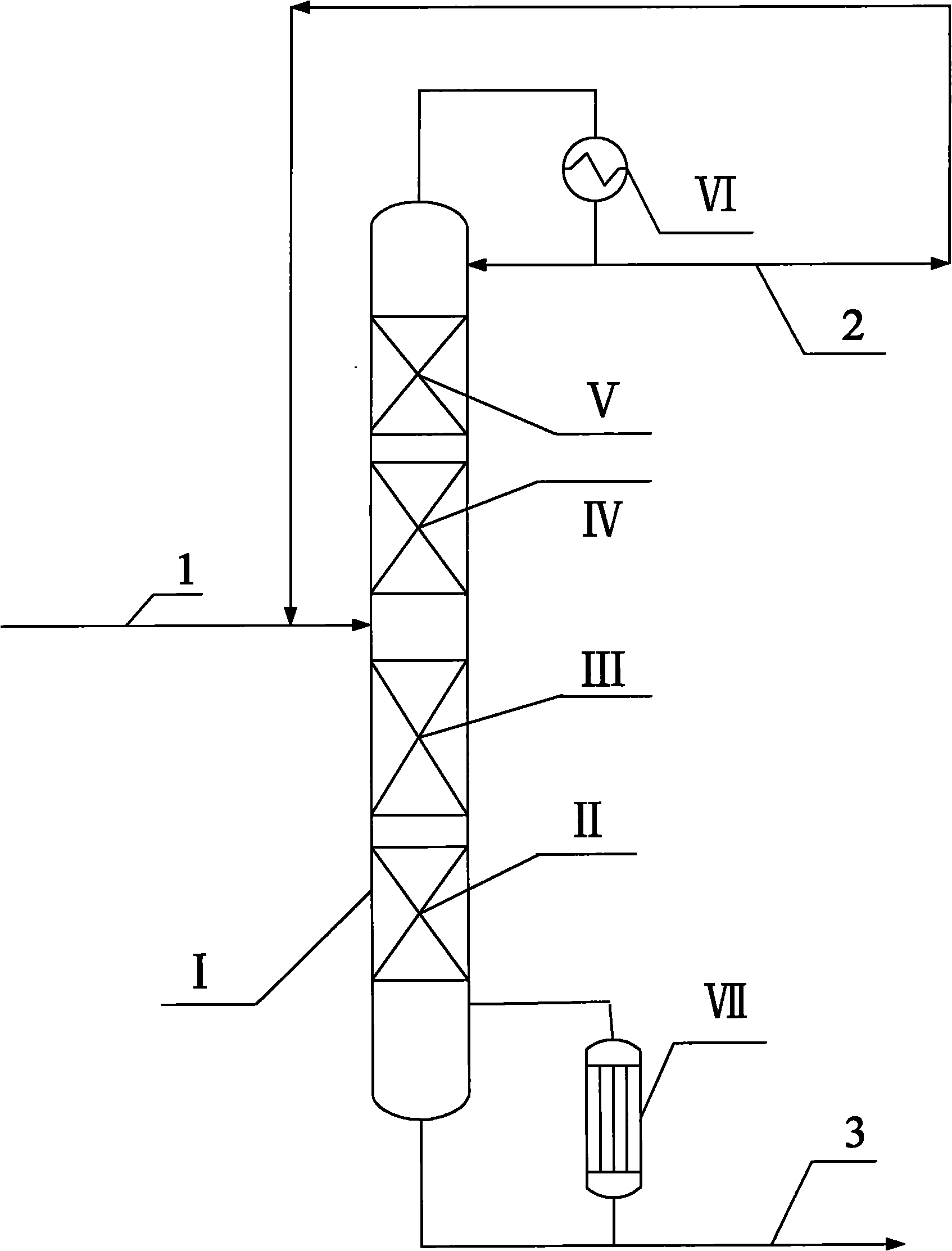

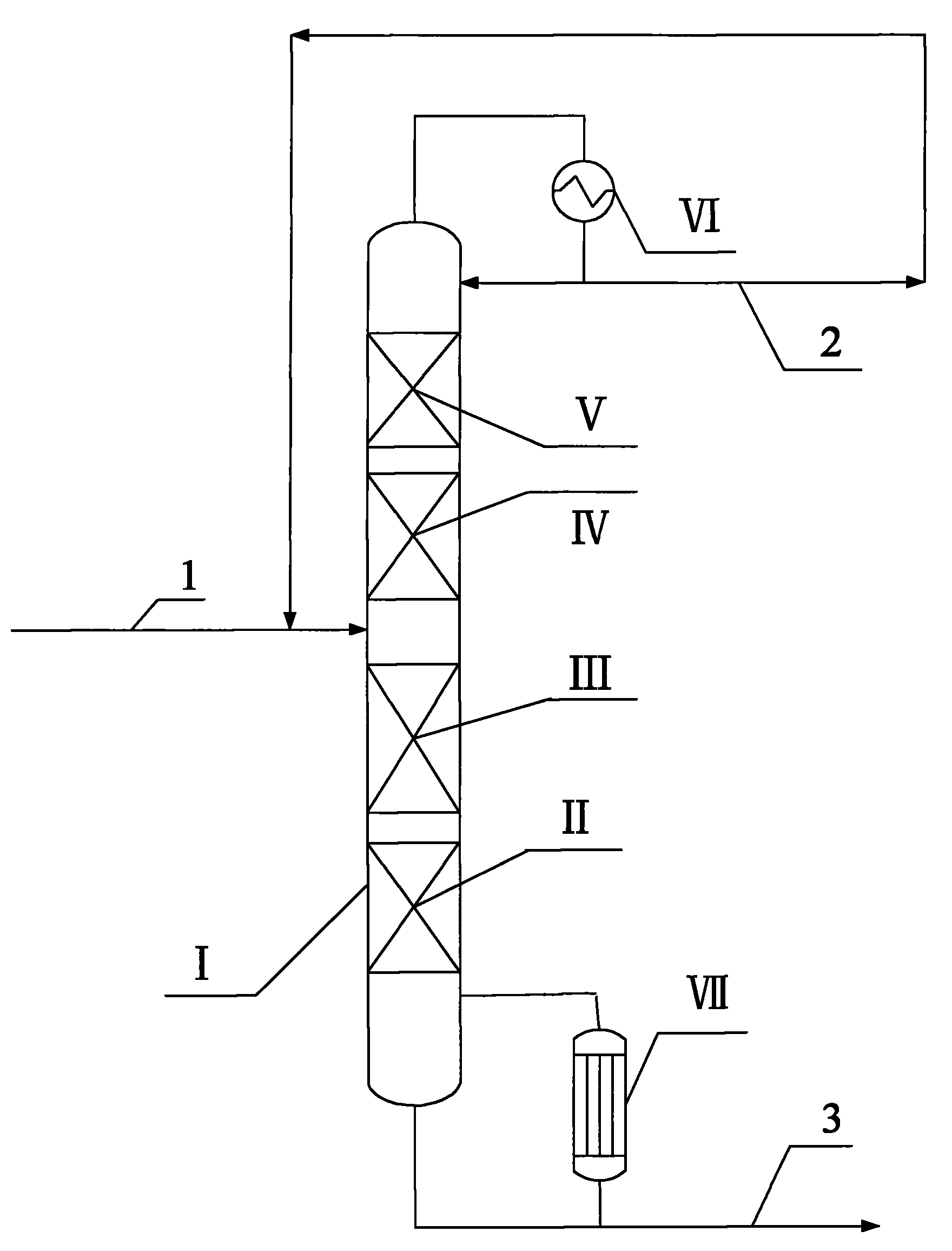

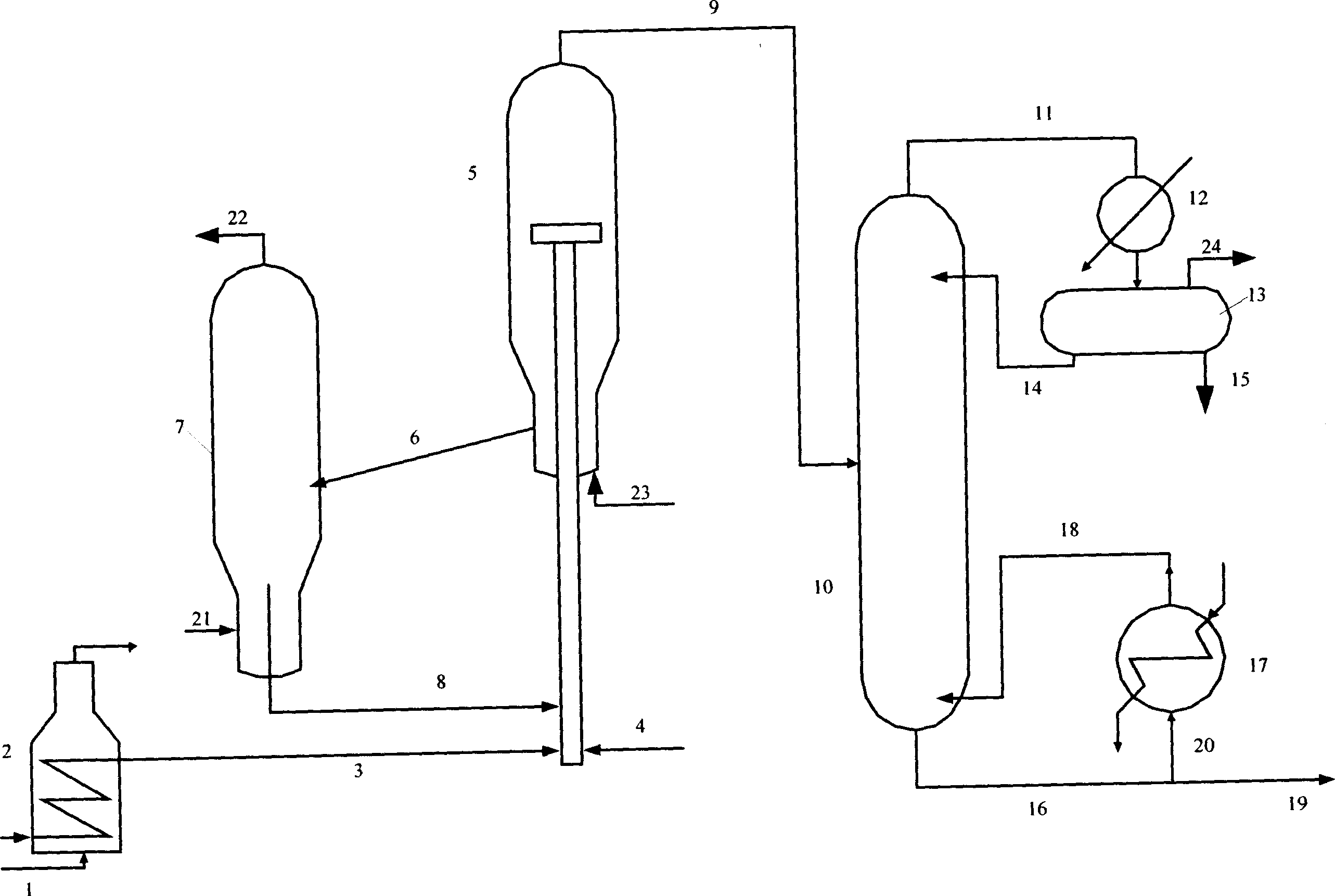

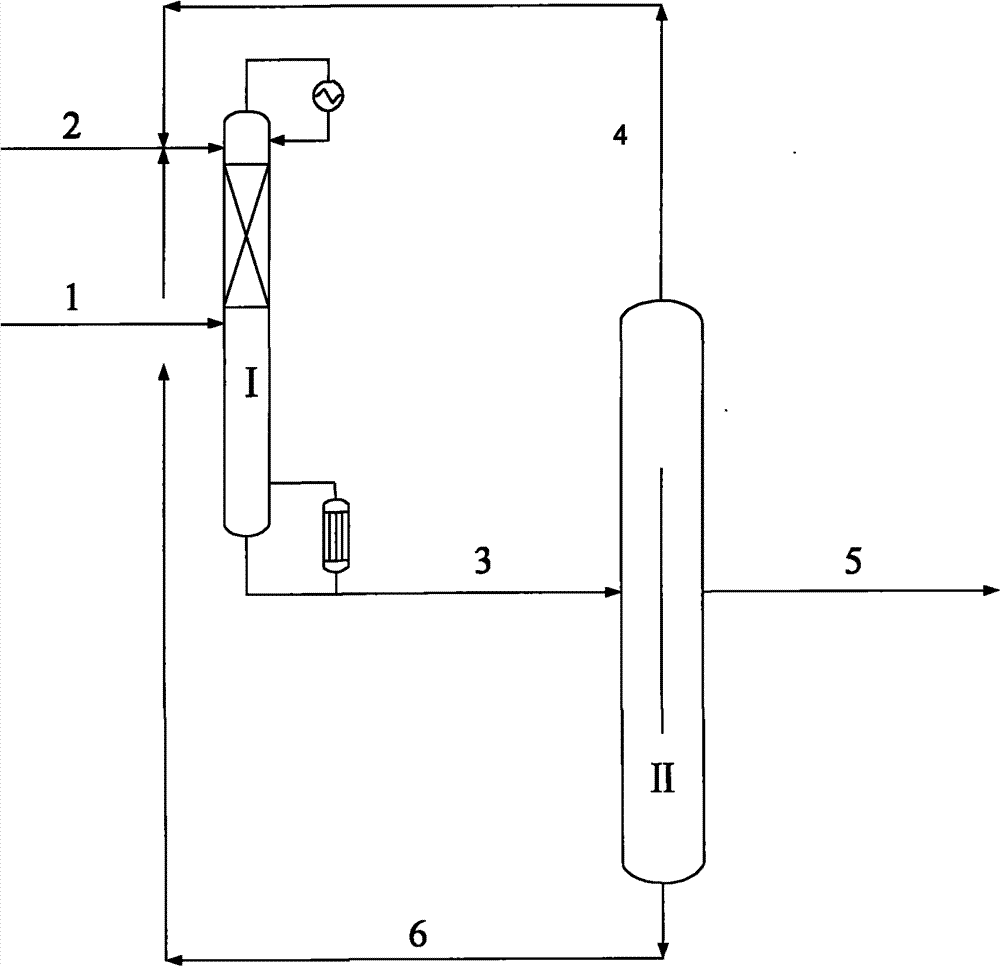

Method for preparing polyformaldehyde dimethyl ether by catalytic distillation

ActiveCN102372615AOvercome the shortcomings of difficult temperature control and short catalyst lifeOvercome the shortcoming of short lifeOrganic chemistryOrganic compound preparationReboilerReactive distillation

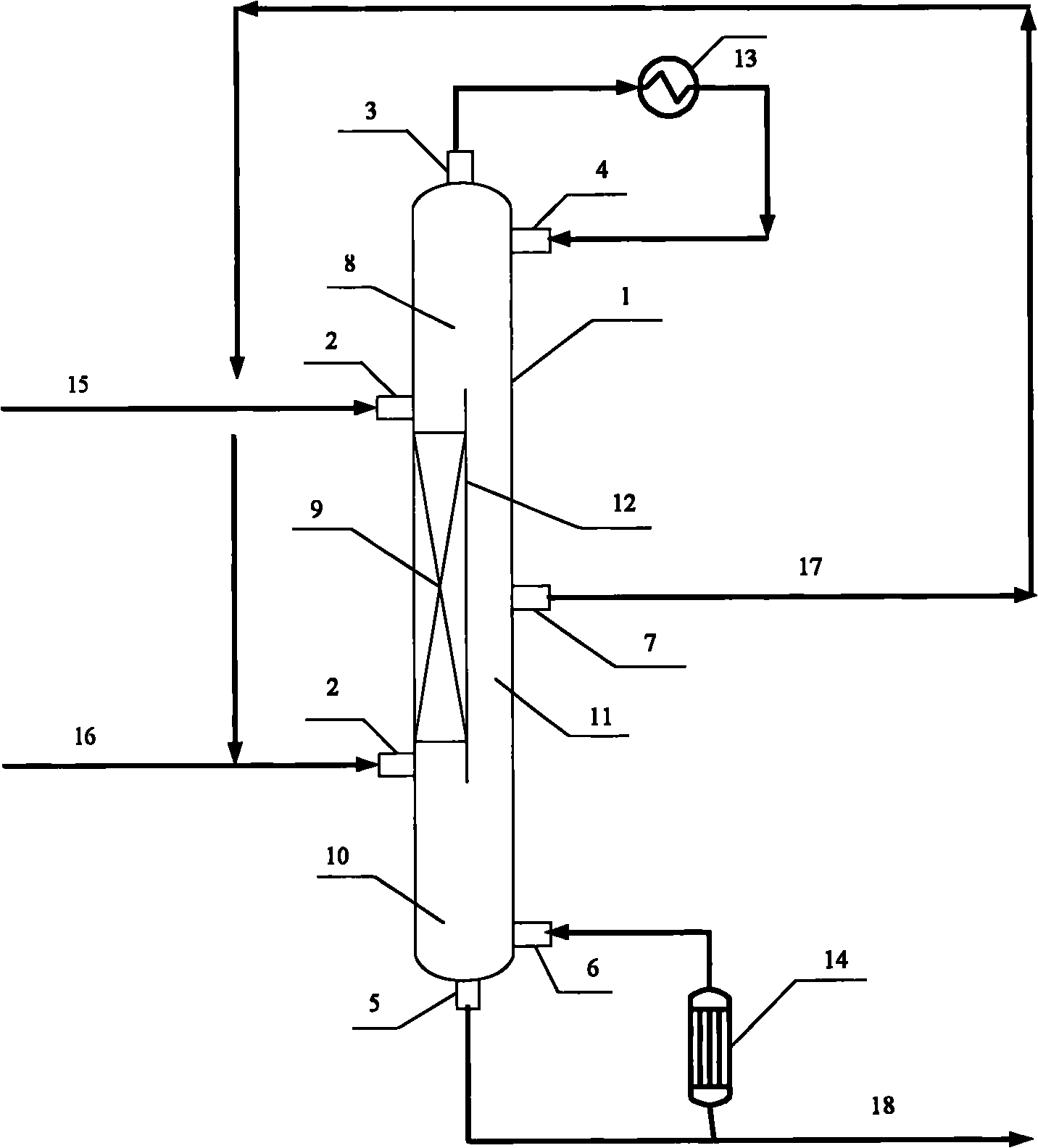

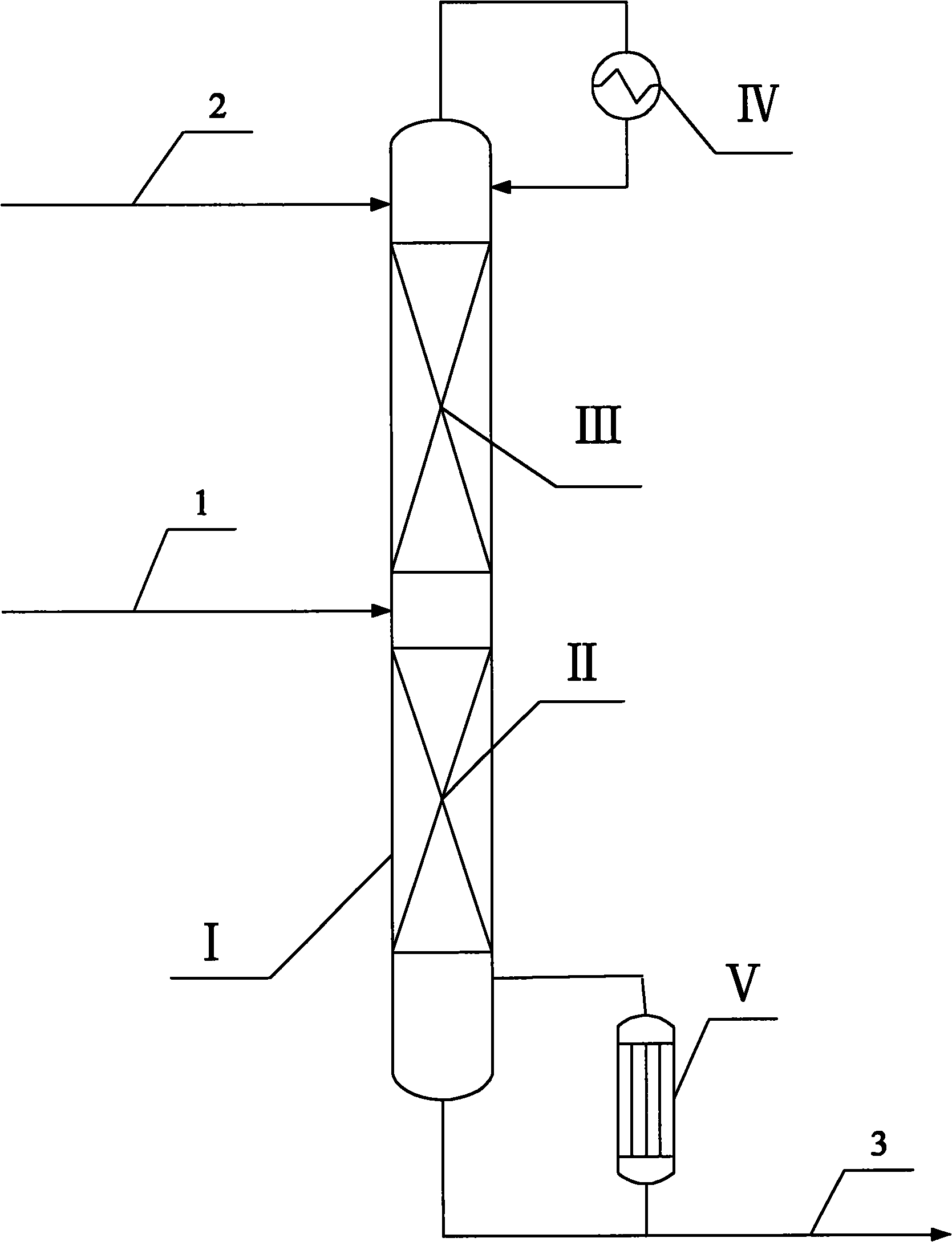

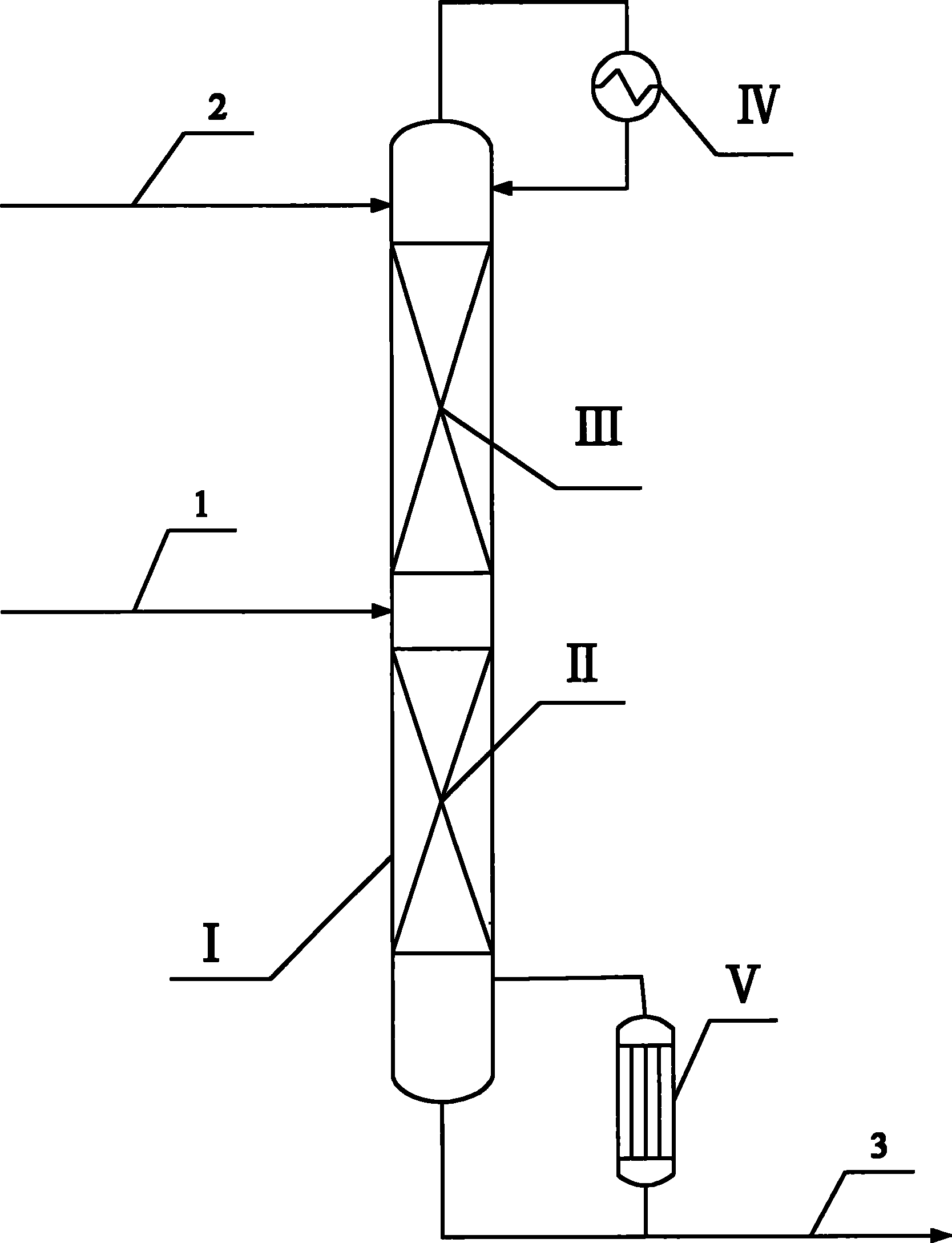

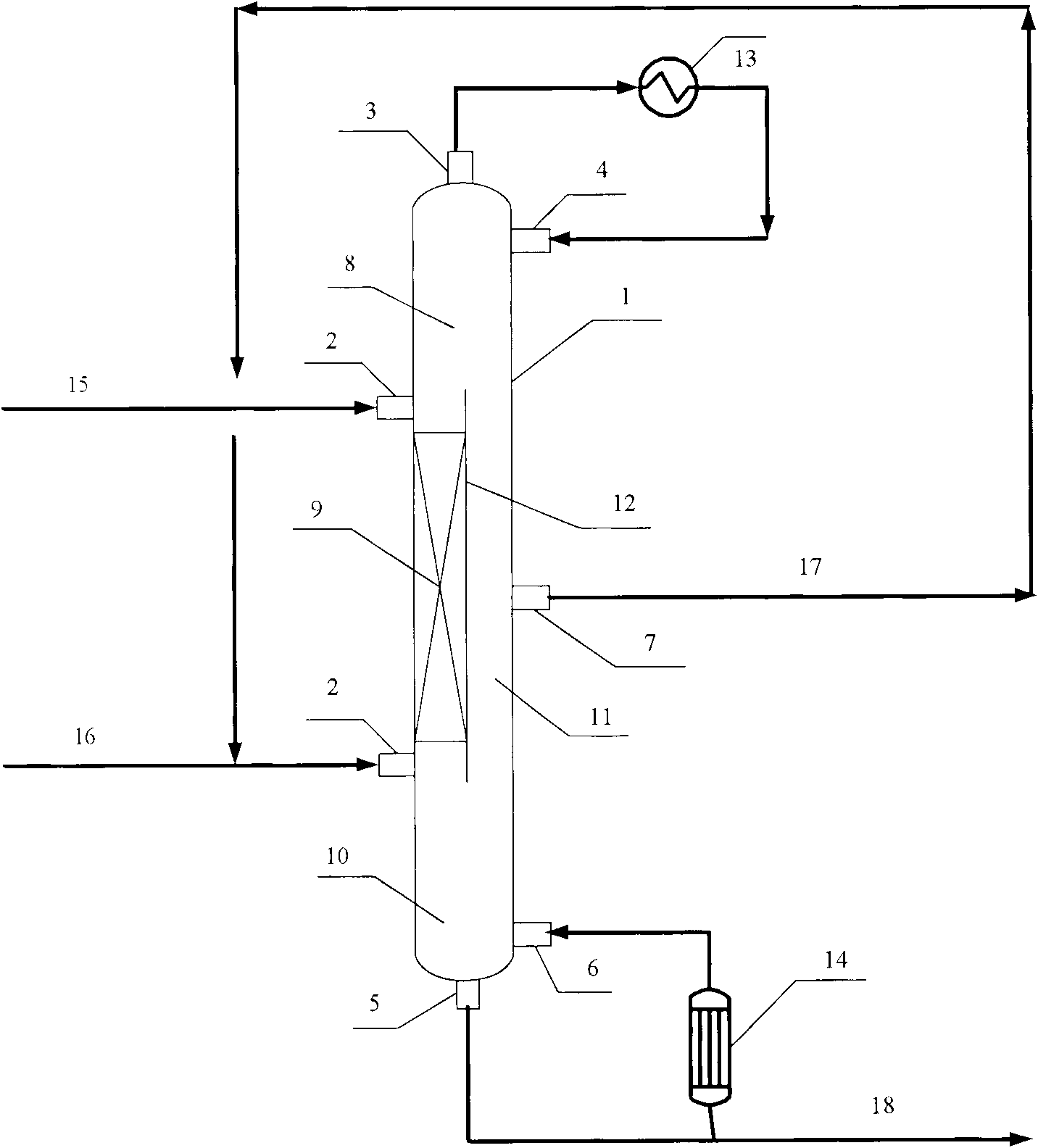

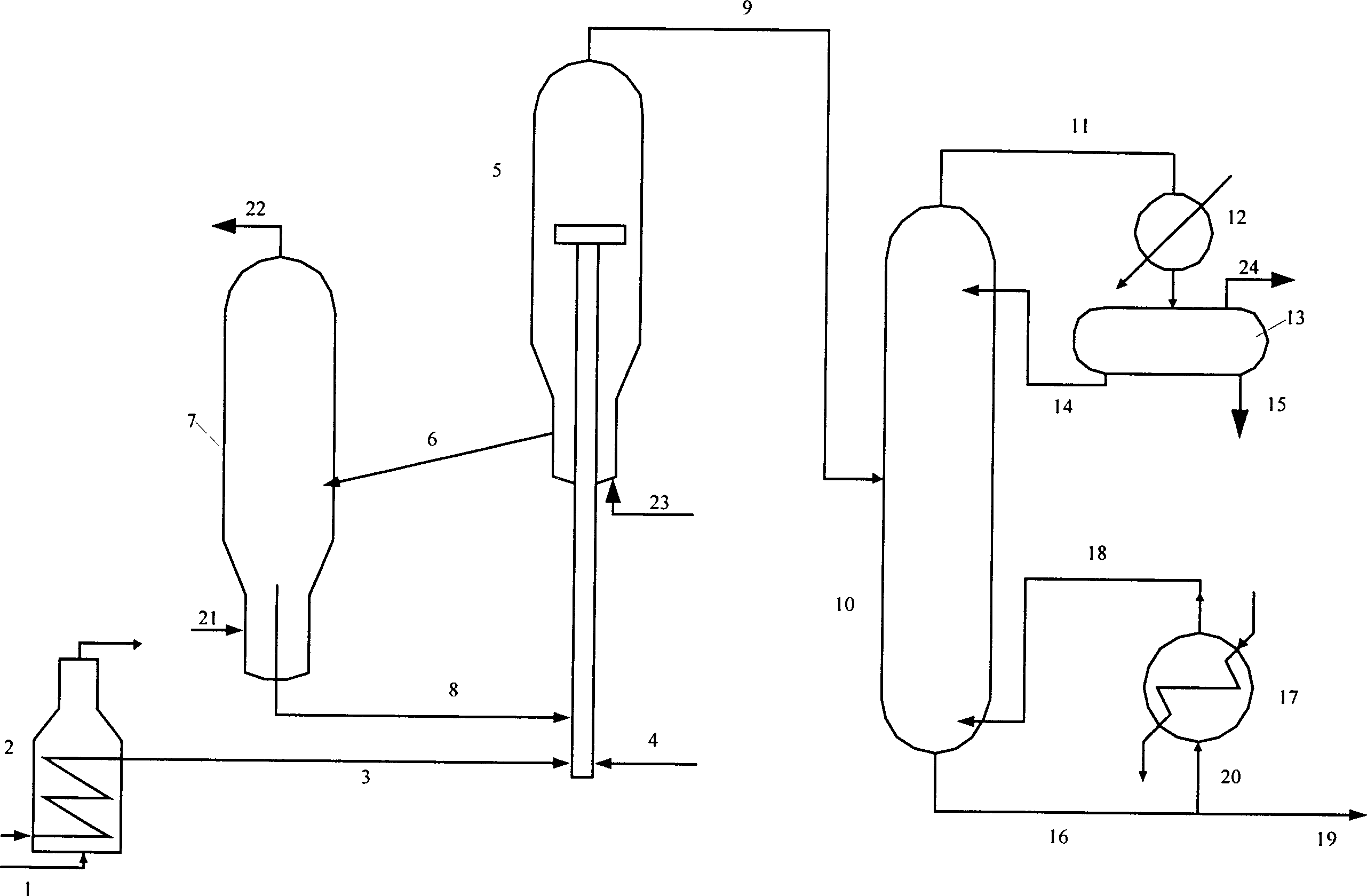

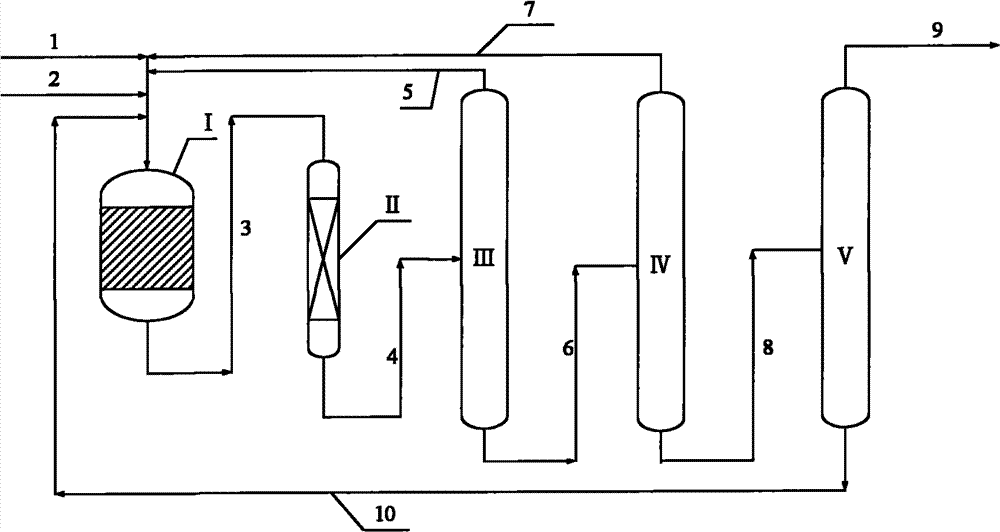

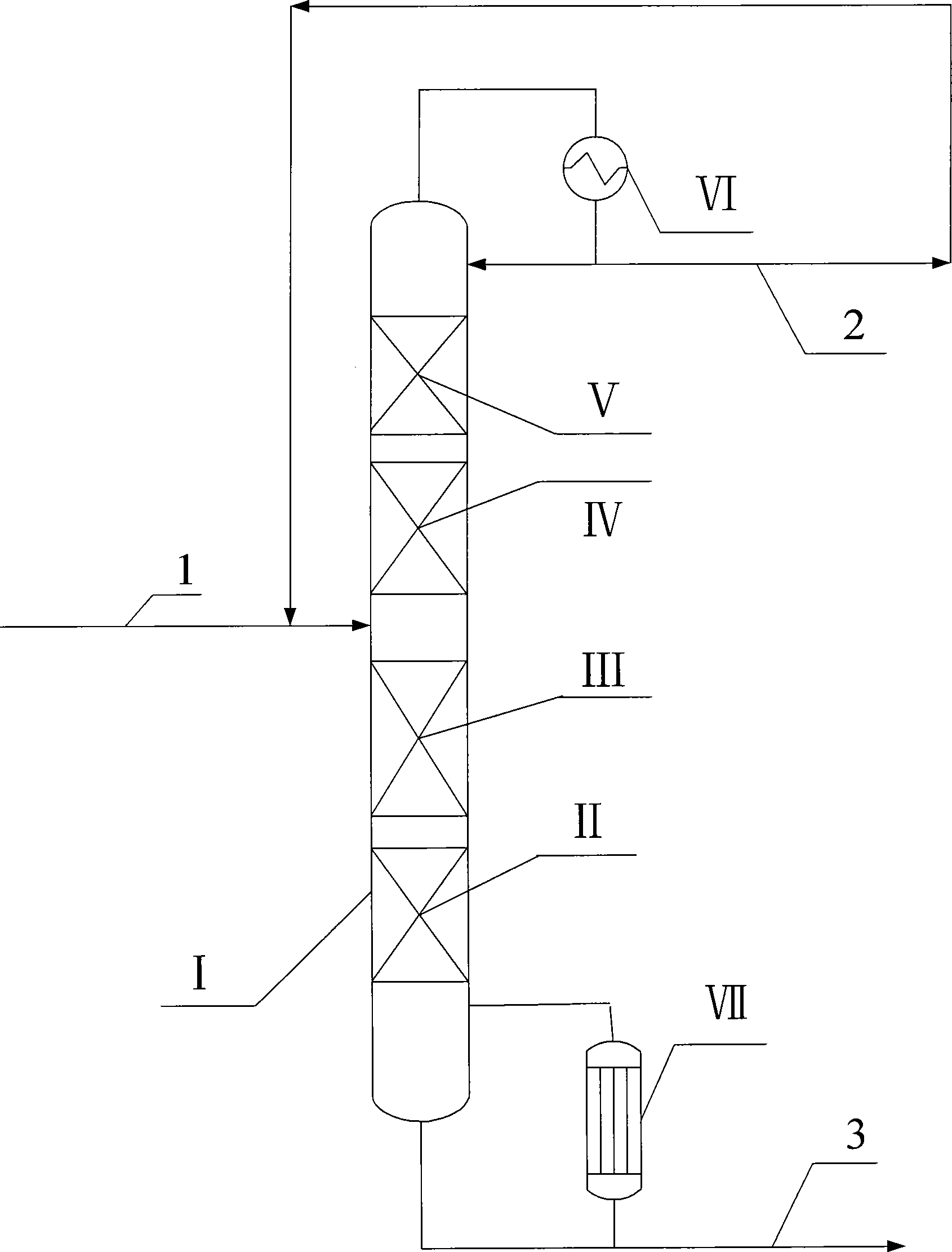

The invention relates to a method for preparing polyformaldehyde dimethyl ether by catalytic distillation. By the method, the problems of a low conversion rate of trioxymethylene and low selectivity of poly methoxyl dimethyl ether (DMM3-8) in the production of the polyformaldehyde dimethyl ether at present are mainly solved. In the method, methylal and the trioxymethylene are separated while reacting in a reaction distillation separation tower body, steam on a tower top is subjected to total reflux after being condensed, light components are extracted from a lateral line of a separation tower and return to the tower, a solution containing the polyformaldehyde dimethyl ether is extracted from a tower bottom, the trioxymethylene enters the reaction distillation separation tower body from the top of a reaction section, the methylal and the returned light components can enter the reaction distillation separation tower body from any position of the reaction section, and a reaction distillation separation tower comprises the reaction distillation separation tower body, a tower top condenser and a tower bottom reboiler. Through the technical scheme, the problems are better solved. The method can be used for the industrial production of the polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

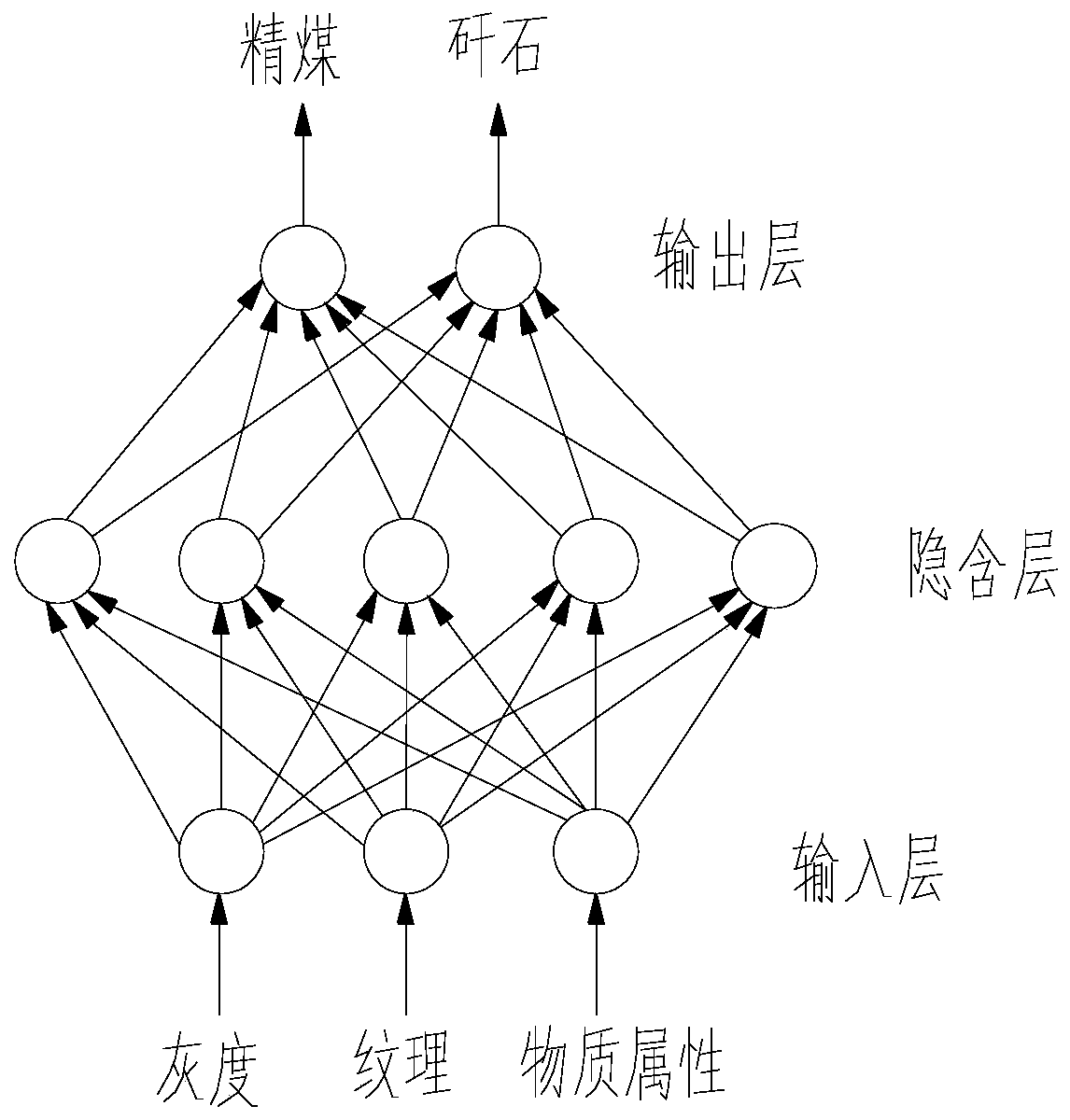

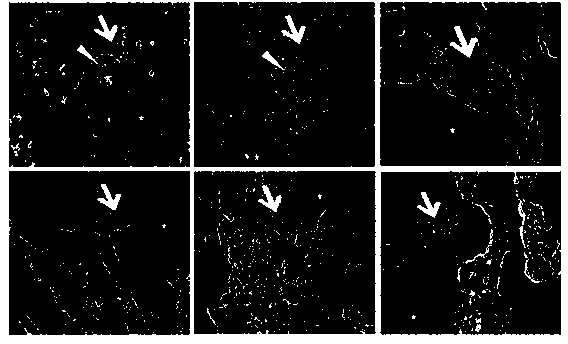

Intelligent dry waste discharge system based on true dual energy X-rays

InactiveCN110773454AStrong adaptabilityReduce manpower inputMagnetic separationSortingProcess engineeringManipulator

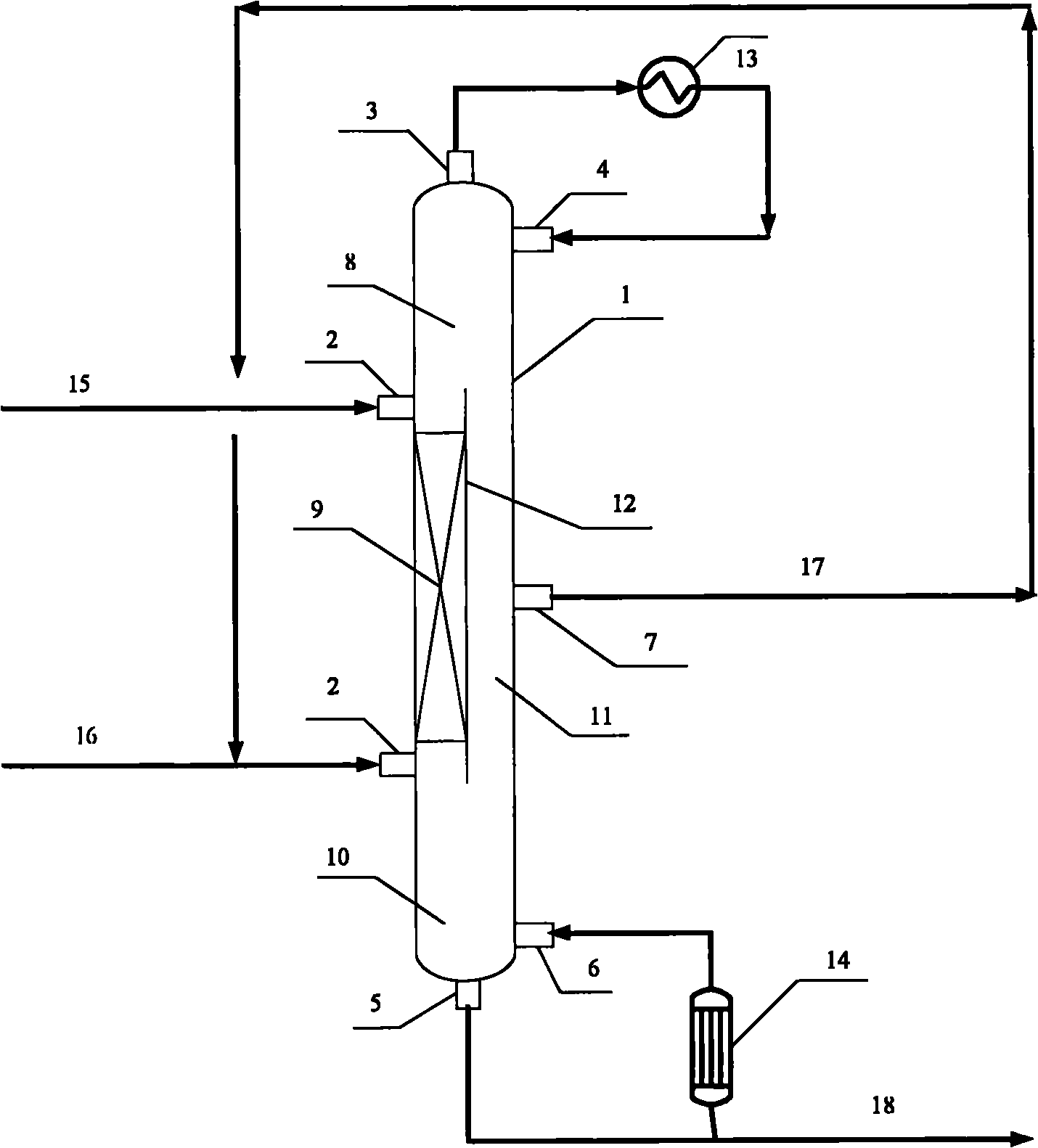

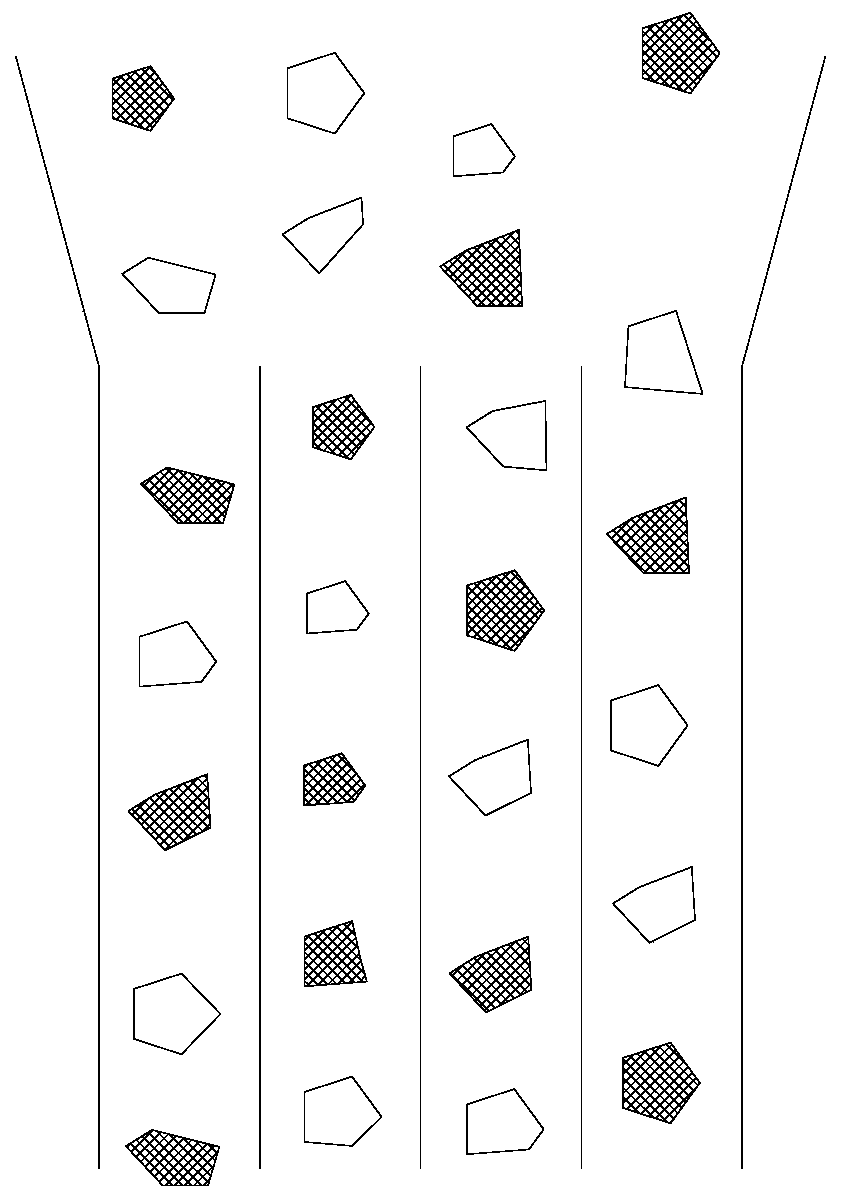

The invention relates to the field of coal preparation and waste discharge, in particular to an intelligent dry waste discharge system based on true dual energy X-rays. The intelligent dry waste discharge system includes a feeding mechanism, a conveying mechanism, a recognition mechanism and a sorting mechanism. The feeding mechanism is composed of a feeding funnel and a spray desliming device, the outer part of the feeding funnel is in an inverted cone shape, and the inner part of the feeding funnel is laid with wear-resistant porcelain plates which can reduce the abrasion of funnel wall surfaces; the spray desliming device is composed of spray pipes and a high-frequency sifter; the conveying mechanism is composed of an electronic belt scale which can monitor the feeding quantity in realtime, an electromagnetic iron remover which can reduce the contamination of sundries, a belt cleaner which can clean fine materials, and a lining-up device capable of forming a plurality of regular coal flows; the recognition mechanism is composed of an X-ray generator generating the X-rays with different intensity, a detector receiving the X-rays, an imaging upper computer, a BP neural network, and a lead isolation room; and the sorting mechanism is composed of a positioning device, a manipulator, and a PLC control cabinet. According to the intelligent dry waste discharge system based on thetrue dual energy X-rays, adaptability to coal is strong, intelligent recognition is realized, therecognition accuracy is high, and at the same time, coal-dust pollution is reduced.

Owner:ANHUI UNIV OF SCI & TECH

Preparation method for polyoxymethylene dimethyl ether

ActiveCN102372612AOvercome uncontrollableRapid responseOrganic chemistryOrganic compound preparationCatalytic distillationReboiler

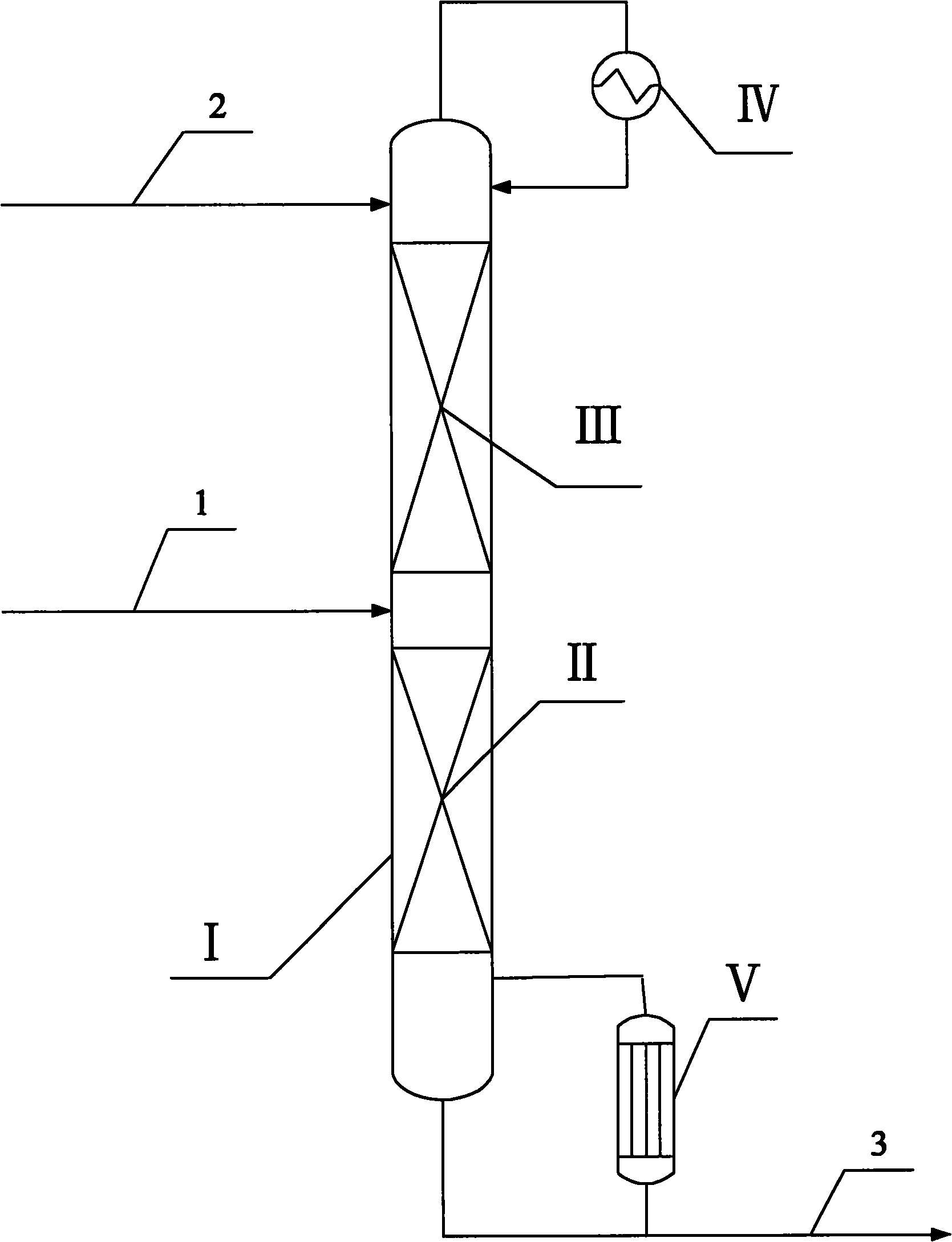

The invention relates to a preparation method for polyoxymethylene dimethyl ether, which mainly solves the problem that the trioxymethylene conversion rates and the selectivity of DMM3 to 8 are low in the production of polyoxymethylene dimethyl ether at present. Methylal and trioxymethylene are adopted to react under effective reaction conditions in a catalytic distillation tower, component separation is carried out during reaction, part of condensed overhead vapour flows back, the other part is recovered, the overhead reflux ratio is 1 to 10, distillate returns into the tower, part of bottom material is vaporized by a reboiler and then returns into the catalytic distillation tower, the rest is adopted as recovered liquid, wherein the methylal, the trioxymethylene and the returning distillate enter between the two reaction sections of the catalytic distillation tower, and the catalyst in the catalytic distillation tower is heterogeneous acidic catalyst. The technical scheme effectively solves the problem, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

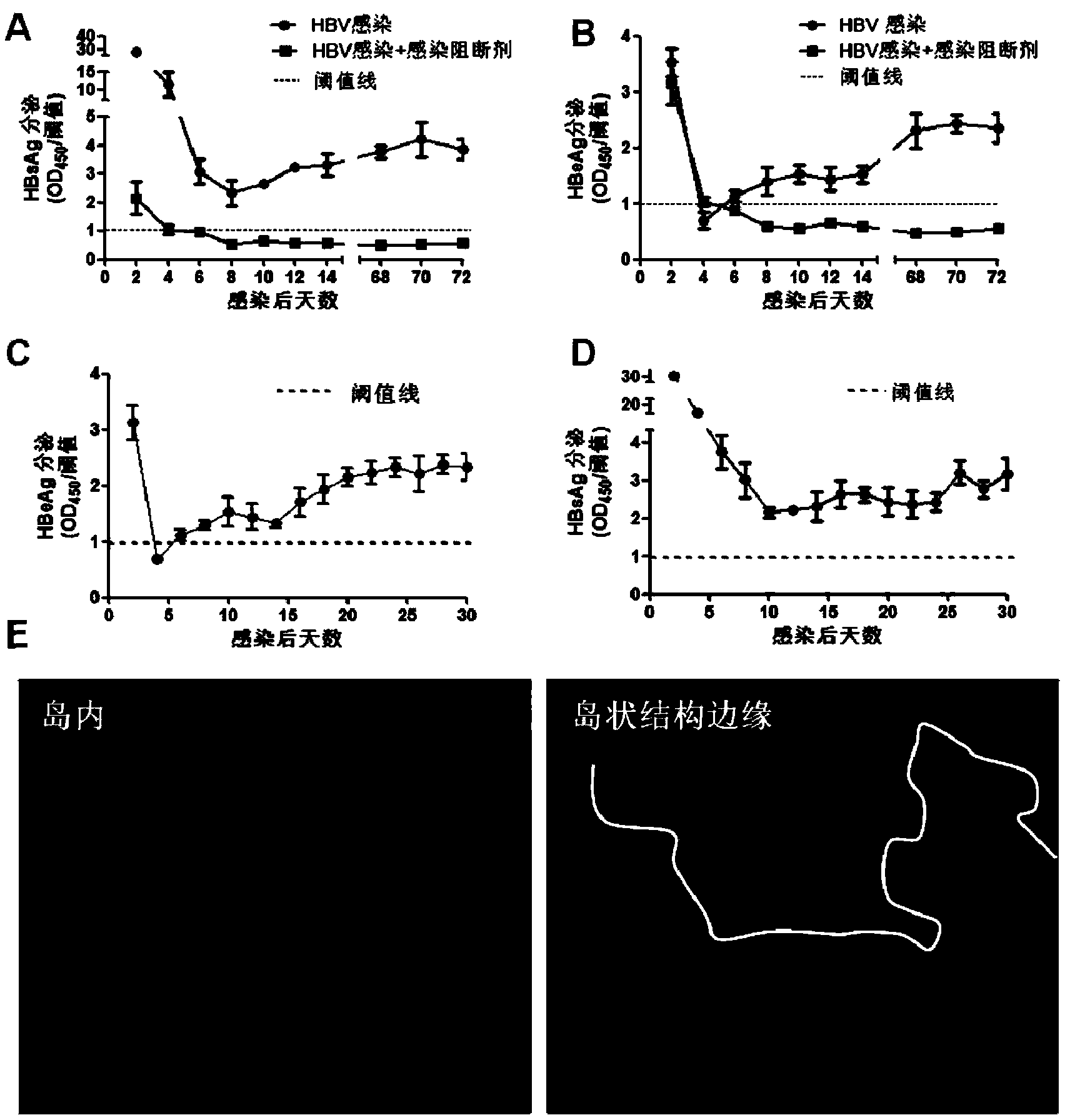

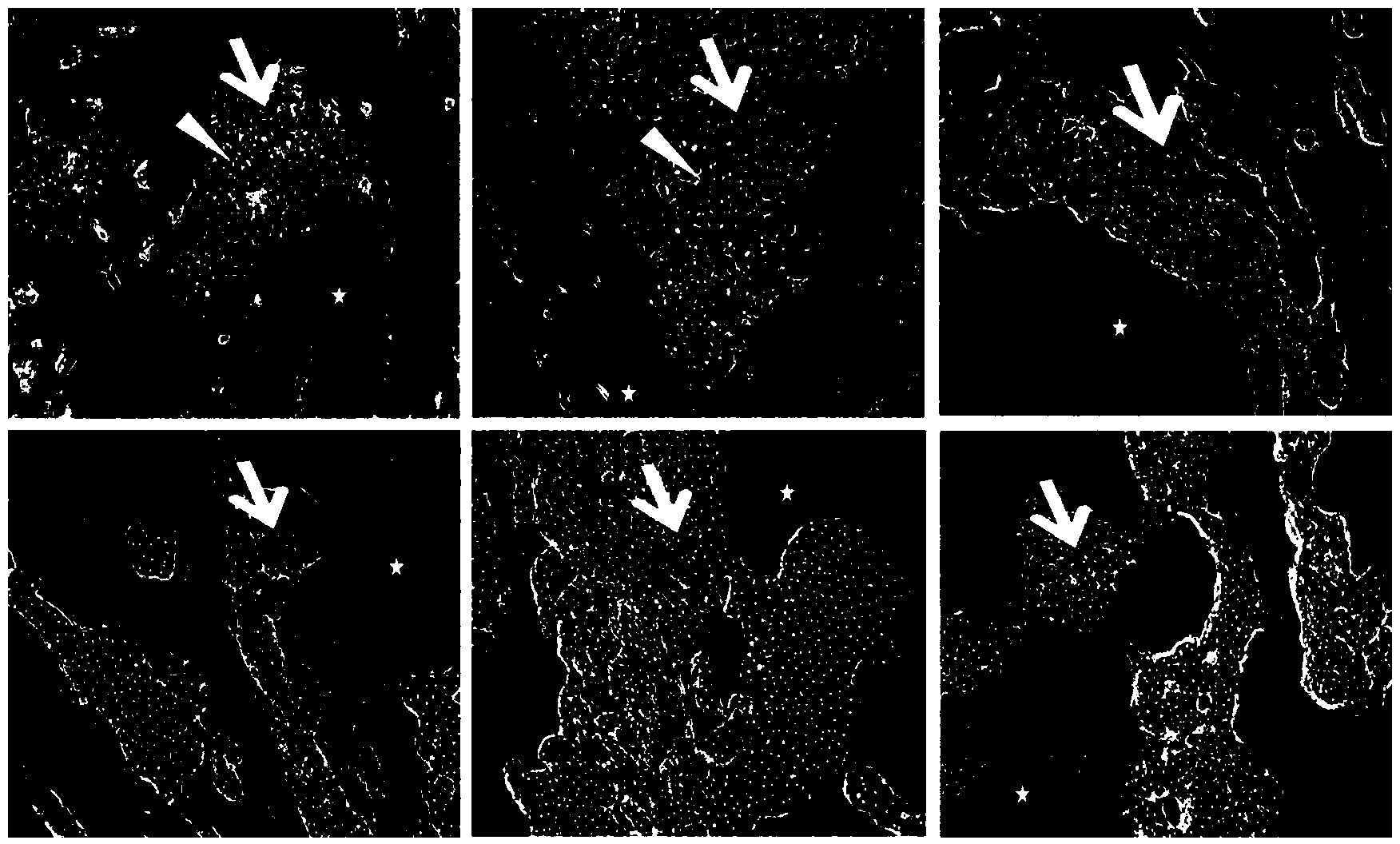

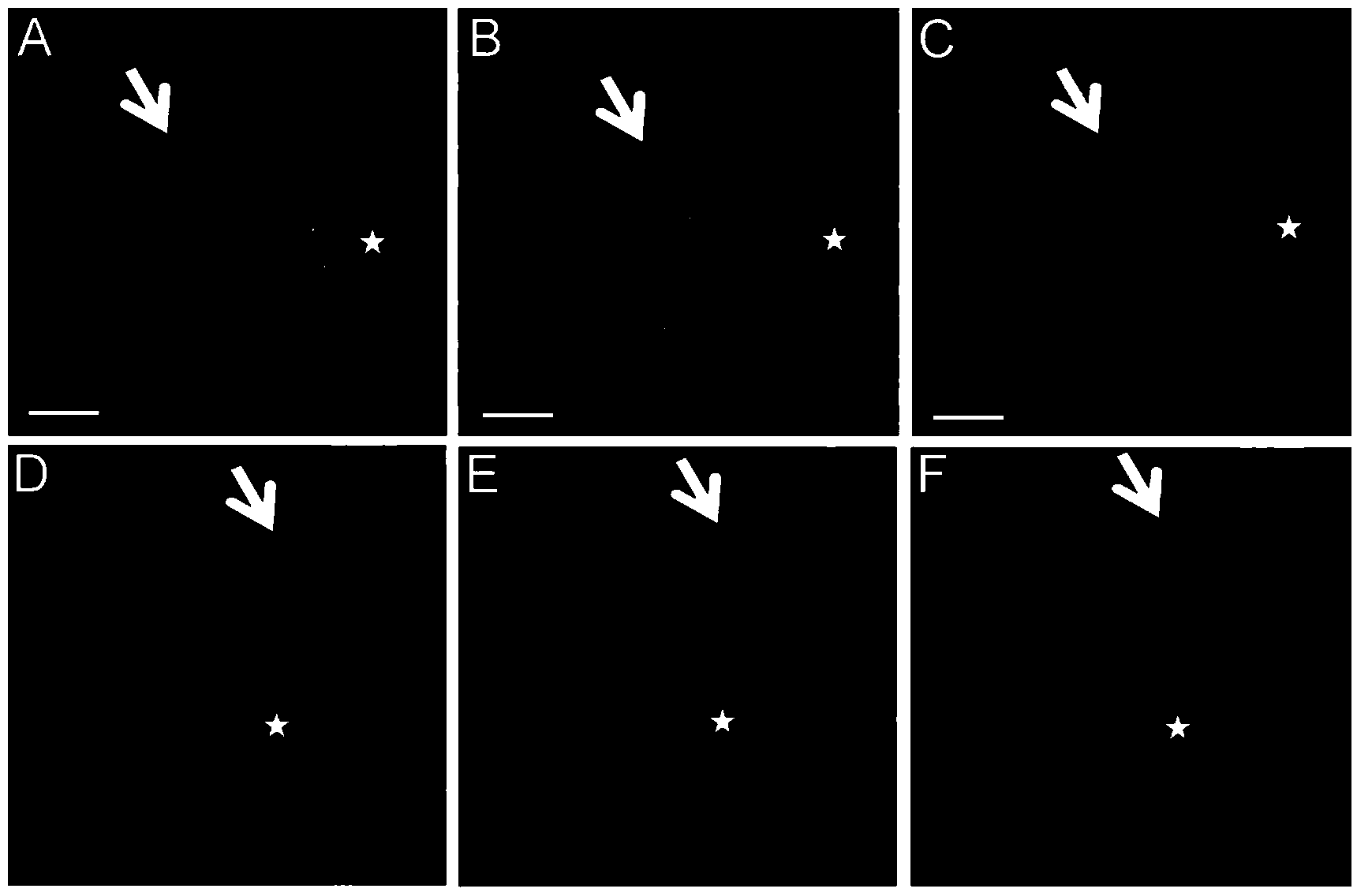

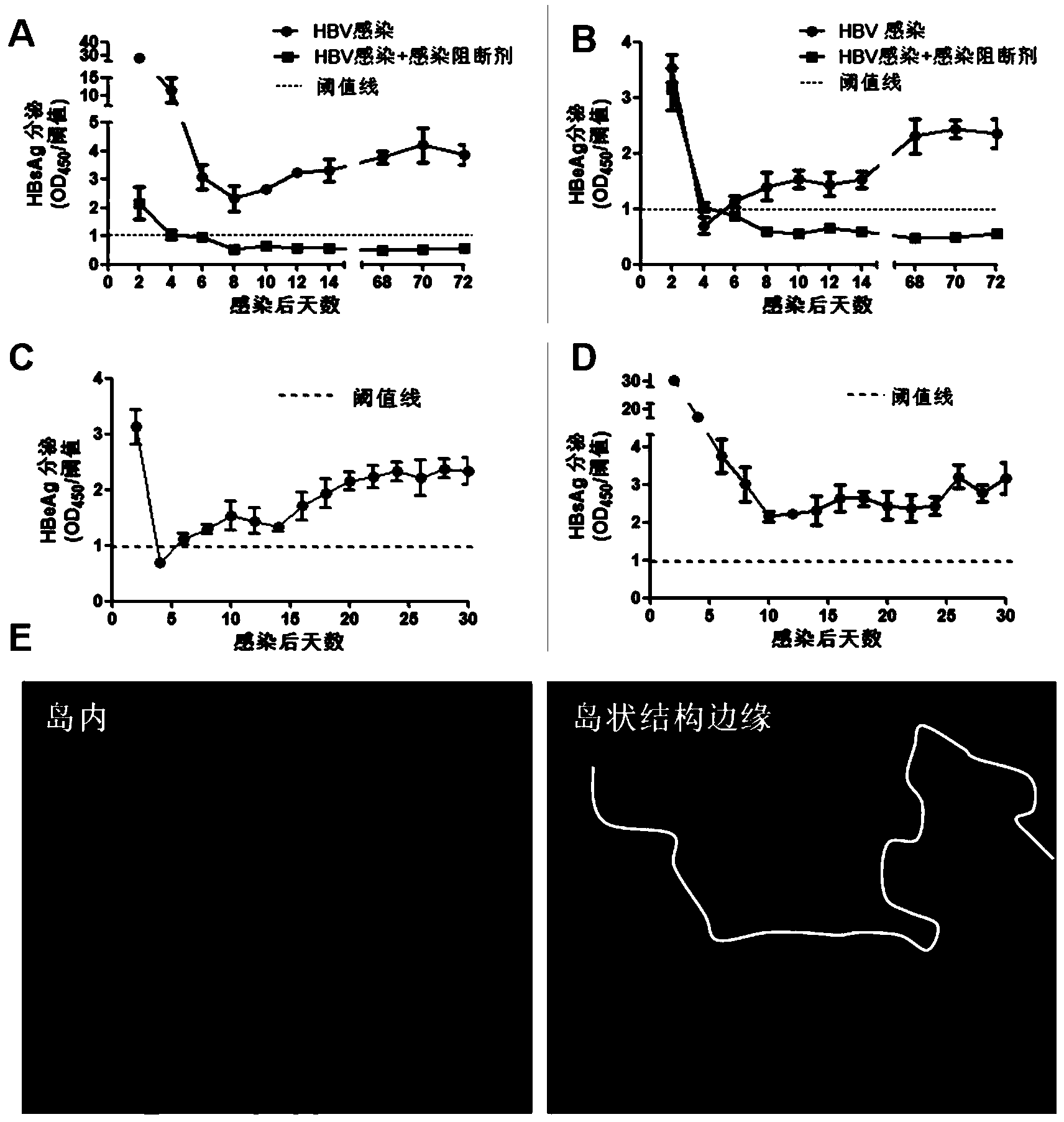

Co-culturing method of human primary hepatocytes and liver nonparenchymal cells

ActiveCN103509751AAchieve in vitro expansionNo blocking operation requiredVertebrate cellsArtificial cell constructsSeparation technologySingle cell suspension

The invention discloses a co-culturing method of human primary hepatocytes and liver nonparenchymal cells. The co-culturing method comprises following steps: fresh hepatic tissue is washed thoroughly with exposed blood vessel perfusate I and perfusate II until elasticity of the hepatic tissue is lost, and complete digestion is realized; the hepatic tissue is delivered into a culture dish filled with a cell washing liquor, and is screened so as to obtain a single-cell suspension; a culture plate or a culture dish coated with collagen is inoculated with the single-cell suspension with a low inoculum density so as to obtain monolayer co-cultured cells with a fusion degree of 100% in the presence of growth factors; and a maintaining culture medium containing 2% DMSO is added into the culture plate or the culture dish for culturing, and then a liver island structure is formed by accumulation of hepatic cells, wherein the liver island structure is surrounded and invaded by liver nonparenchymal cells. Routine hepatocyte separation technology is employed in the co-culturing method, in vitro long-term culturing of hepatocytes as long as 120 days are realized, and HBV susceptibility is maintained for as long as 72 days. In addition, the co-culturing method can be used for screening and evaluating anti-HBV medicines, and possesses significant importance on researches of antiviral medicines.

Owner:康珞生物科技(常州)有限公司

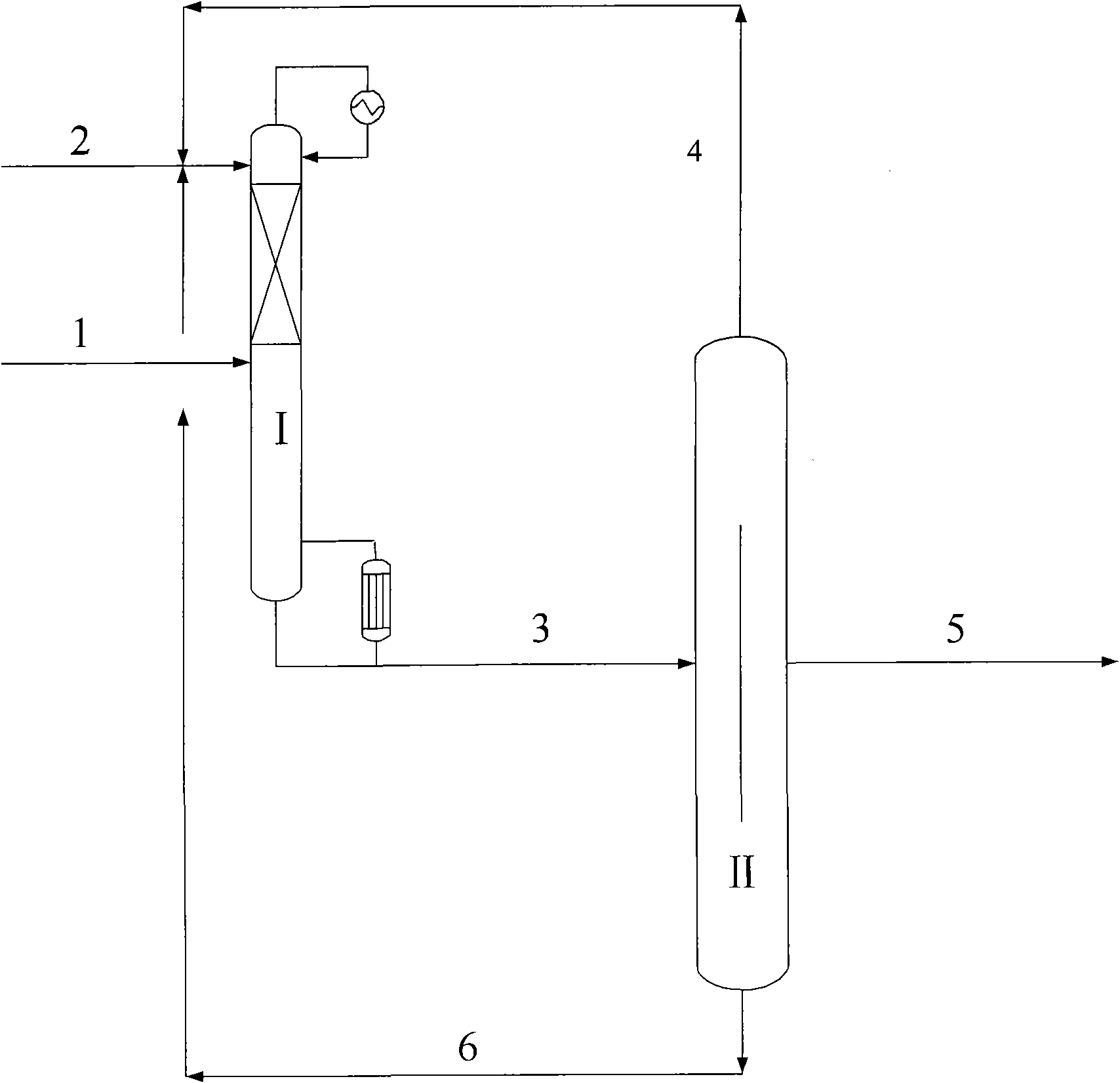

Production method of polyoxymethylene dimethylether

ActiveCN102372614AOvercome the shortcoming of short lifeHigh selectivityOrganic chemistryOrganic compound preparationPolyoxymethyleneReflux

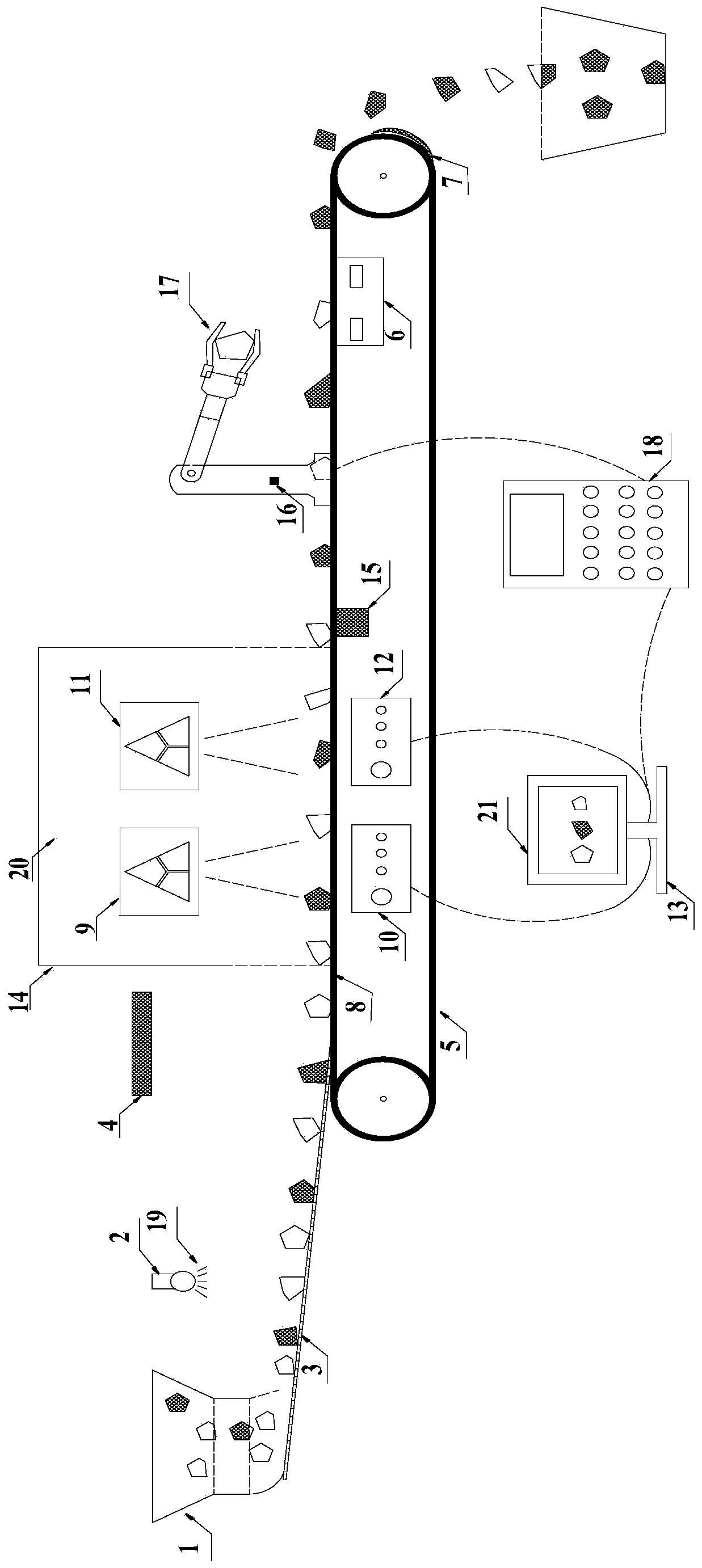

The invention relates to a production method of polyoxymethylene dimethylether and mainly solves the problems of low selectivity of polyoxymethylene dimethylether, complex technology and high energy consumption during the present production process of polyoxymethylene dimethylether. The production method provided by the invention comprises the following steps of: carrying out a reaction between methylal and trioxane in a catalytic distillation column while separating ingredients, condensing steam on the top of the column, followed by reflux, allowing a first part of the materials on the bottom of the column to return to the catalytic distillation column after vaporizing the first part through a reboiler while a second part is used as a production stream I and the weight ratio of the first part materials to the second part materials is 1-10: 1; allowing the production stream I to enter into a divided wall distillation column for separation, and collecting polyoxymethylene dimethylether DMM3-8 from the produced central part in the divided wall distillation column. The technical scheme provided by the invention greatly solves the problems and can be used in the industrial production of polyoxymethylene dimethylether.

Owner:CHINA PETROLEUM & CHEM CORP +1

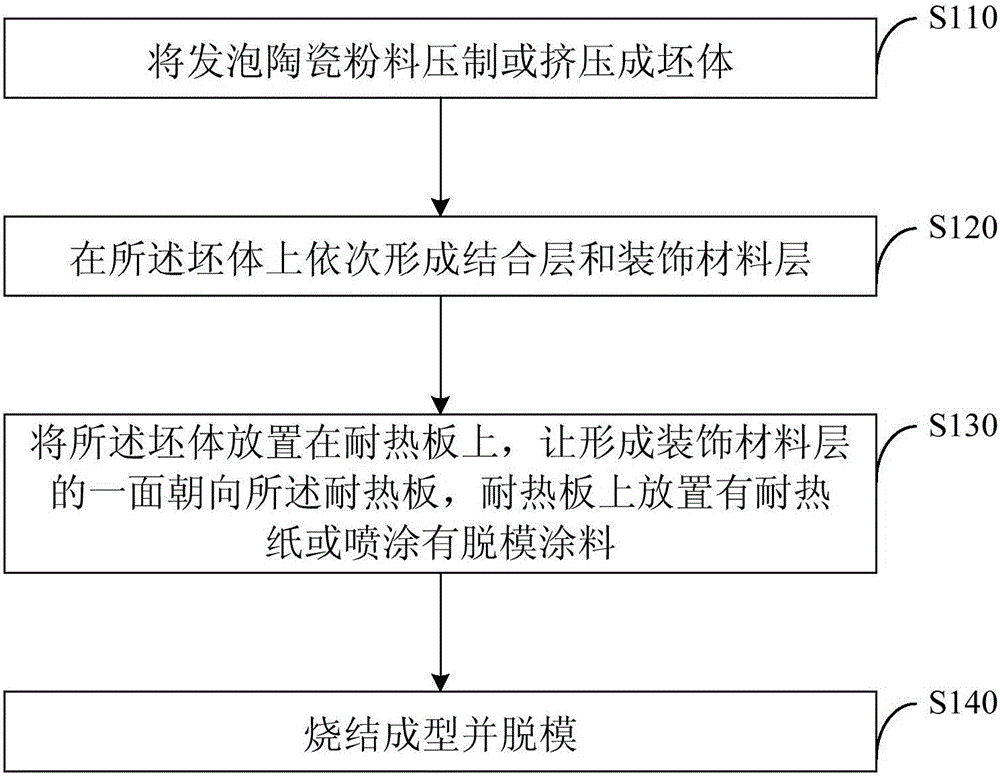

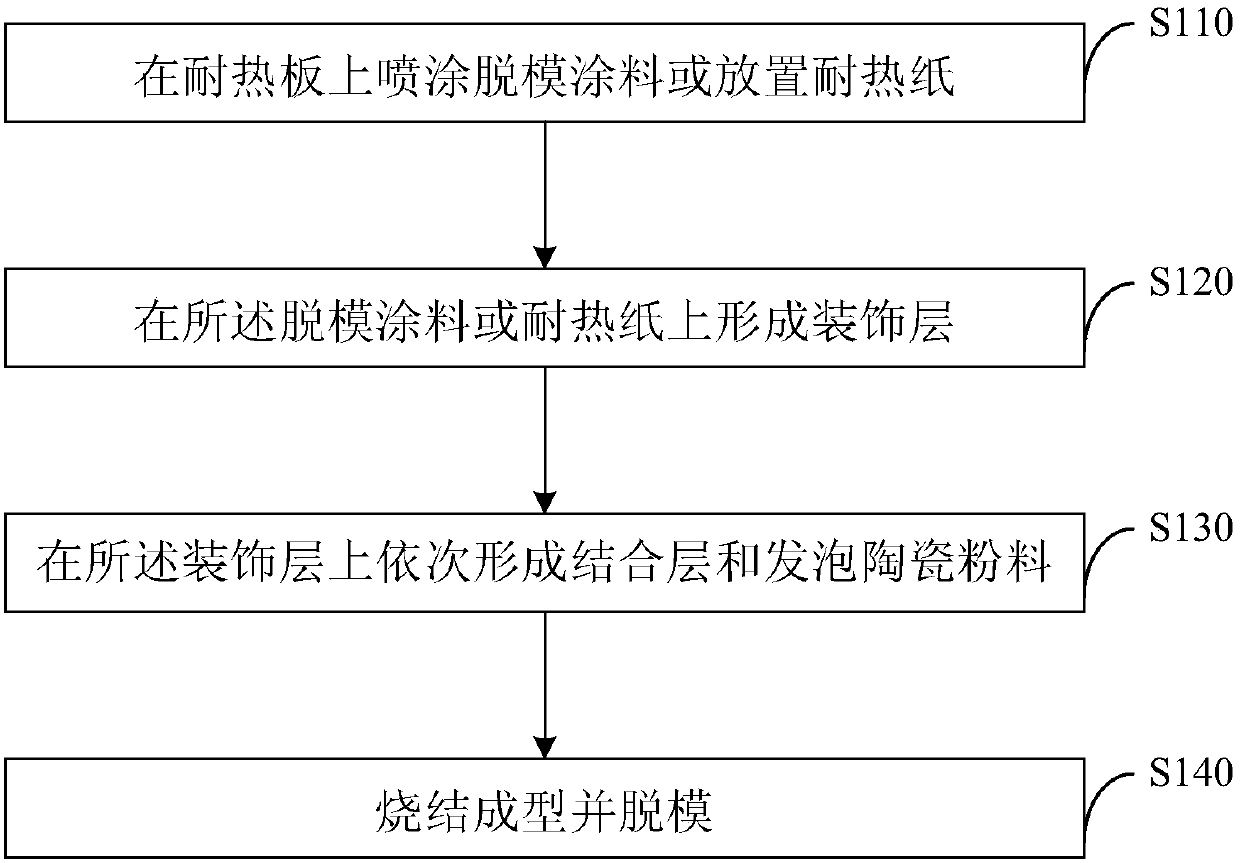

Manufacturing method for heat preservation decoration ceramic tile

ActiveCN105693205AOvercome the shortcoming of short lifeReduce production processCeramic materials productionCeramicwareBrickHot Temperature

The invention relates to the technical field of building materials, and discloses a manufacturing method of a heat preservation decoration ceramic file. The method includes the steps of pressing or extruding foaming ceramic powder into a green body, sequentially forming a bonding layer and a decoration layer on the green body, putting the green body on a heat-resistant plate, making the face forming the decoration layer face the heat-resistant plate, putting heat-resistant paper on the heat-resistant plate or coating the heat-resistant plate with demolding paint, and conducting sintering, forming and demolding. In the method, the green body made from the foaming ceramic powder and the decoration layer are sintered together at a high temperature and integrally formed, manufacturing procedures are reduced, and the manufacturing cost is saved.

Owner:湖南写生绿色建筑科技有限公司

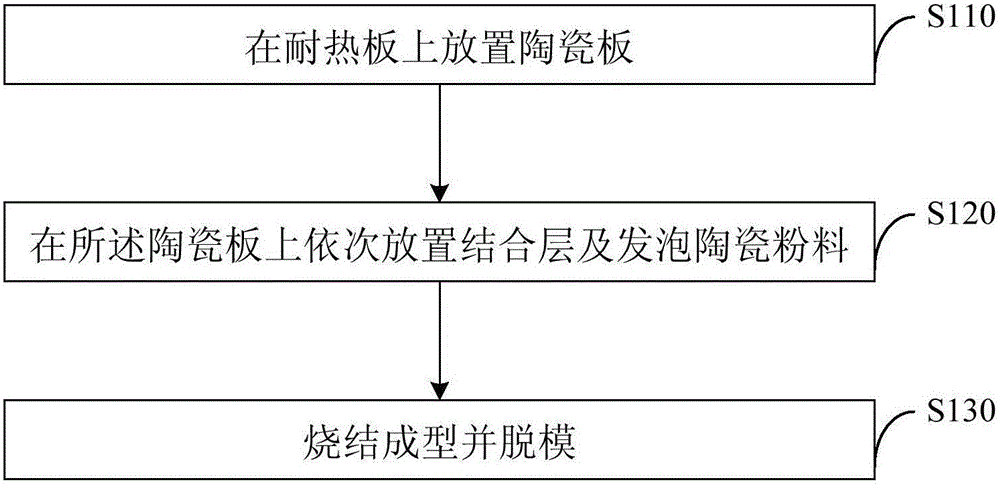

Making method of thermal insulation decorative ceramic tiles

InactiveCN105777070ASolve the problem of complex production process and high production costOvercome the shortcoming of short lifeCeramic materials productionCeramicwareBrickThermal insulation

The invention relates to the technical field of building materials, and discloses a making method of thermal insulation decorative ceramic tiles. The making method comprises the following steps: placing ceramic plates on heat resistant plates; sequentially placing bonding layers and foaming ceramic powder on the ceramic plates; carrying out sinter molding and demoulding. According to the making method of the thermal insulation decorative ceramic tiles disclosed by the invention, the foaming ceramic powder and the ceramic plates served as decorative layers are subjected to high temperature sintering together and formed integrally to reduce the making procedures and the making cost.

Owner:重庆歌德陶瓷玛赛克制造有限公司

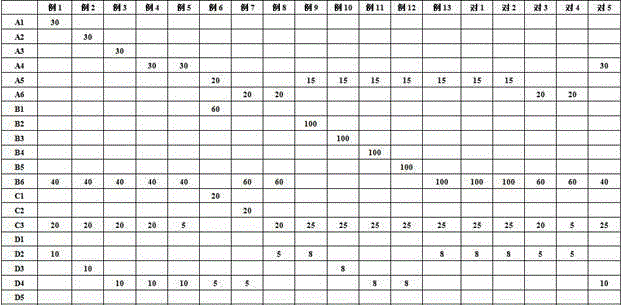

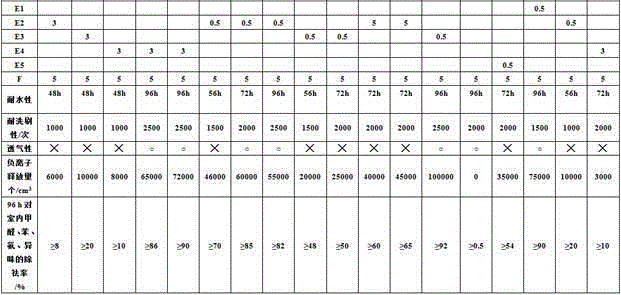

Energy-saving water-based coating adsorbing and degrading formaldehyde and releasing negative oxygen ions

An energy-saving water-based coating adsorbing and degrading formaldehyde and releasing negative oxygen ions is characterized in that the energy-saving water-based coating is prepared from, by weight, at least 15-30 parts of hydroxyl water-based resin, 40-100 parts of a first packing and 5-25 parts of a second packing, wherein the first packing is one or more of diatomite, coarse whiting and ash calcium, and the second packing is selected from montmorillonite and / or sericite. The energy-saving water-based coating has good breathability, water resistance, formaldehyde degradation performance and other excellent performance and can be used on the basic layers and face layers of building walls.

Owner:XIAN TIJI BUILDING DECORATION MATERIAL CO LTD

Self-adaptive parallel sealing and welding method for microelectronic packaging in high vacuum state

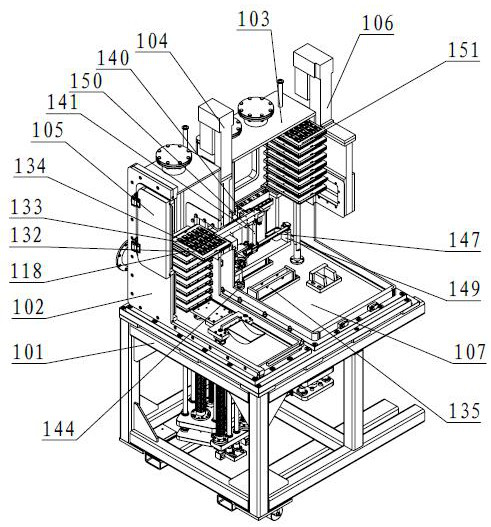

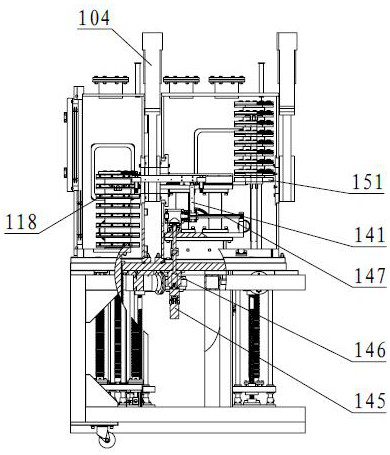

ActiveCN114029661ALow investment costOvercome the shortcoming of short lifeWelding/cutting auxillary devicesAuxillary welding devicesThin shellsWeld seam

The invention discloses a self-adaptive parallel sealing and welding method for microelectronic packaging in a high vacuum state, and solves the problem of how to complete high-quality parallel seal welding of a cover plate and a tube shell of a thin-shell device at low cost in a vacuum environment so as to improve the sealing and welding yield. A floating parallel welding wheel support is arranged, two parallel welding wheels on the support are pressed on parallel welding seams between the cover plate and the tube shell in a floating mode, weights are arranged at the top end of the parallel welding wheel support, and the welding pressure of the parallel welding wheels on the welding seams is adjusted by increasing or reducing the number of the weights, so that the adjustment of the self-adaptive welding pressure in the welding process is realized; a shoulder-pole-shaped semi-square-shaped jacking frame body is arranged between the left parallel welding wheel support and the right parallel welding wheel support, the floating parallel welding wheel supports are lifted and lowered through jacking connection of eccentric wheels to the semi-square-shaped jacking frame body, and conversion between a welding state and a to-be-welded state of the two parallel welding wheels is completed. and the sealing and welding quality of the packaging assembly is greatly improved.

Owner:西北电子装备技术研究所

Method for producing polyformaldehyde dimethyl ether

ActiveCN102372613AImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationReboilerCatalytic distillation

The invention relates to a method for producing polyformaldehyde dimethyl ether. By the method, the problems of a low conversion rate of trioxymethylene and low selectivity of poly methoxyl dimethyl ether (DMM3-8) in the production of the polyformaldehyde dimethyl ether at present are mainly solved. In the method, methanol and the trioxymethylene are separated while reacting in a catalytic distillation tower under the effective reaction condition, steam on a tower top is refluxed after being condensed, a first part of materials at a tower bottom is vaporized by a reboiler and returns to the catalytic distillation tower, a second part of the materials is used as extraction liquid, and a mass ratio of the first part to the second part is (1-15):1, wherein the trioxymethylene enters the catalytic distillation tower from the tower top, the methanol can enter the catalytic distillation tower from a stripping section to any position on the tower top, and a catalyst in the catalytic distillation tower is a heterogeneous acidic catalyst. Through the technical scheme, the problems are better solved. The method can be used for the industrial production of the polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

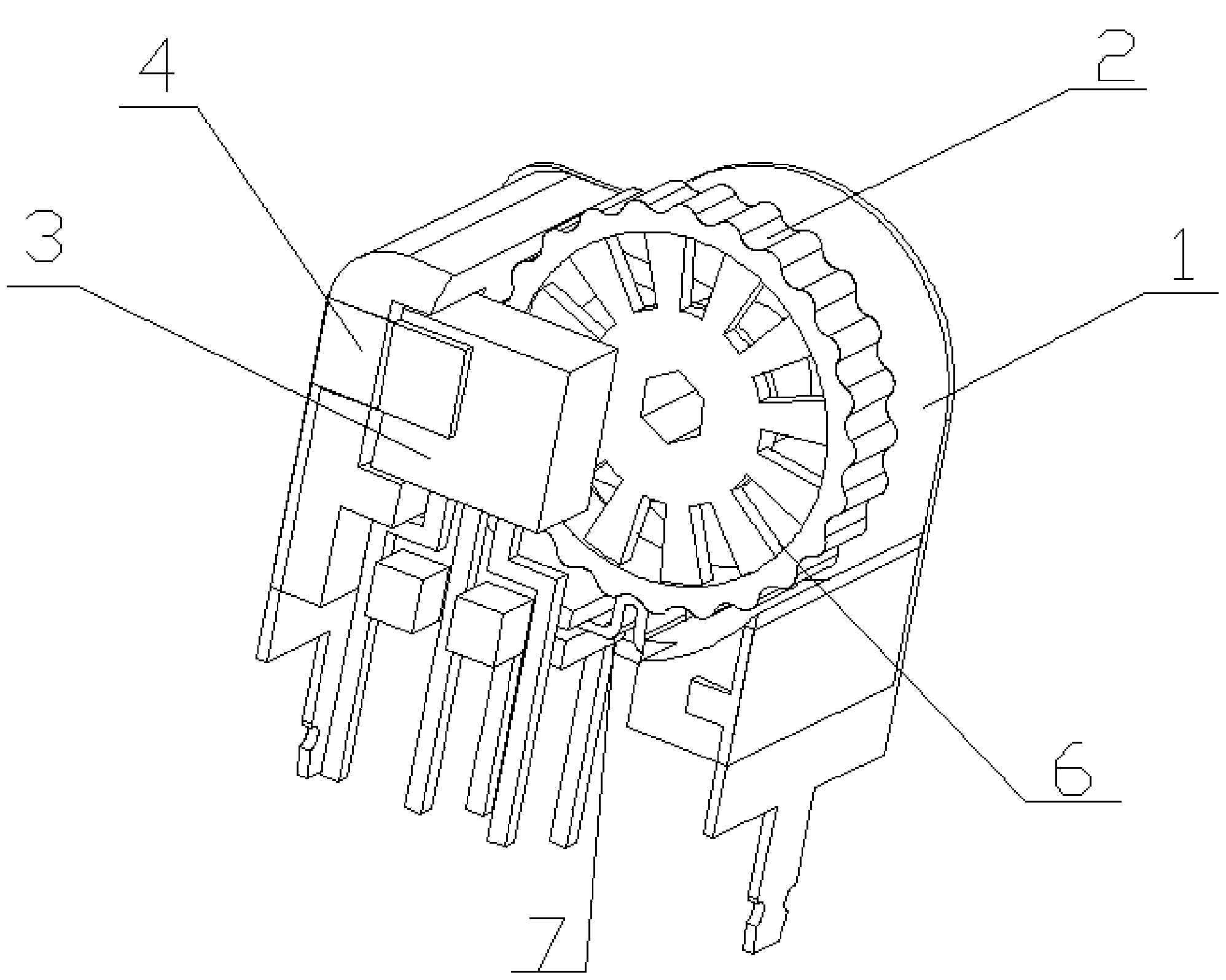

Optical crystal encoder of simple structure

The invention discloses an optical crystal encoder of a simple structure. The optical crystal encoder of the simple structure comprises an encoder body and a grating device arranged inside the encoder body, and further comprises an optical crystal device. The optical crystal device comprises an optical crystal emitting device and an optical crystal receiving device. The optical crystal emitting device is arranged in a containing region of the encoder body and between the encoder body and the grating device. The optical crystal receiving device is arranged on the surface of the grating device and the encoder body, the grating device and the optical crystal device are fixed together through fixing devices. The optical crystal encoder of the simple structure overcomes the defects that a common mechanical encoder is short in service life, the service life of the mechanical encoder depends on the service life of a metal rotary disk and the universal mechanical encoder in the market can be used no more than 500 thousand times. However, the optical crystal encoder can be used infinitely theoretically.

Owner:郝小妮 +1

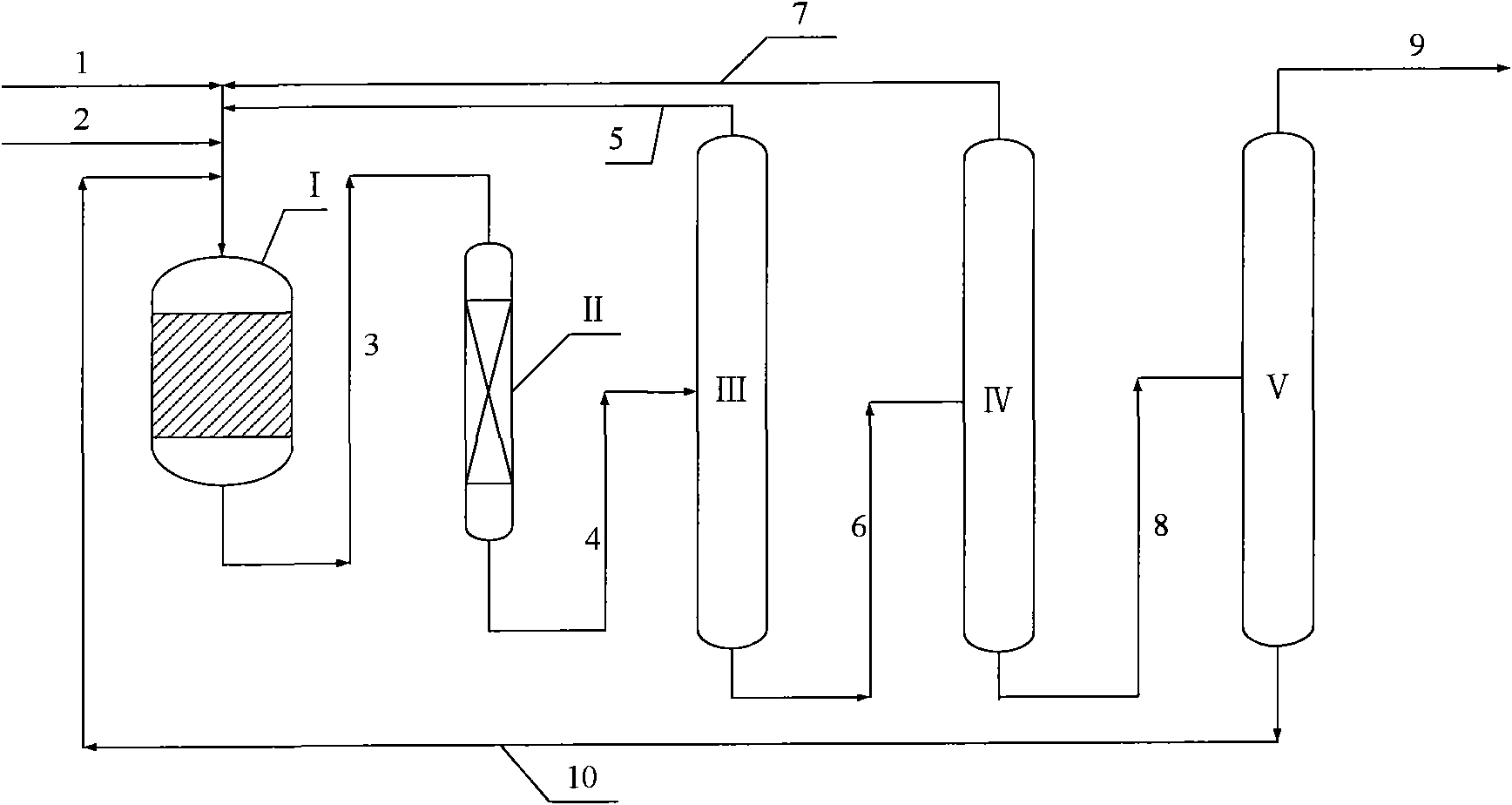

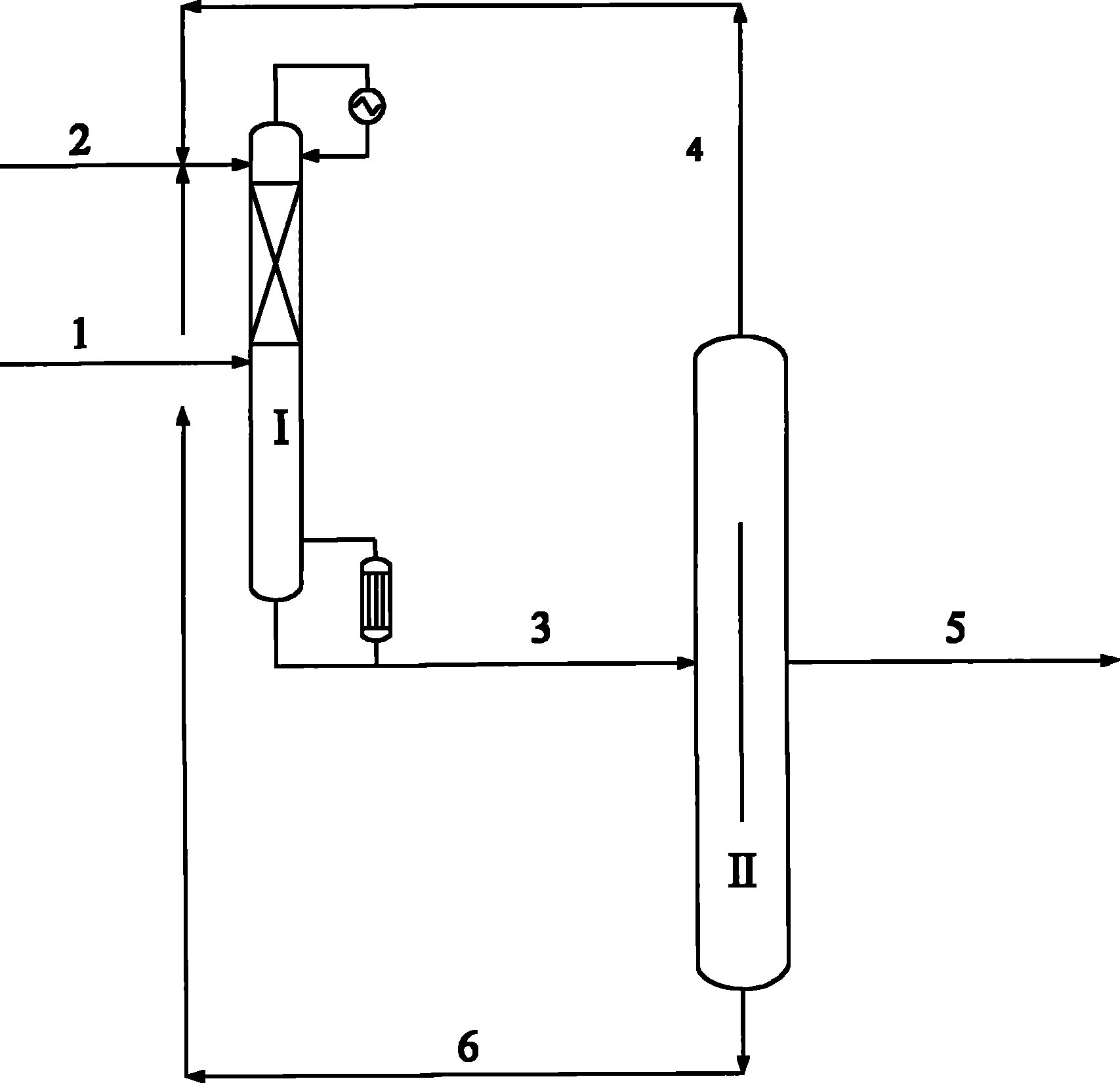

Petroleum fraction alkyl sulfur transferring method

InactiveCN1453335AOvercome the shortcoming of short lifeKeep aliveRefining with solid acidsDistillates petroleumAlkyl transfer

The present invention is petroleum fraction alkyl sulfur transferring method. Heated petroleum fraction and alkylating agent are made to enter movable catalyst reactor, so that the sulfide in petroleum fraction and the alkylating agent produce alkylation reaction under the action of powdered alkylating catalyst. The reaction products are separated to obtain low-sulfur light petroleum fraction and high--sulfur heavy petroleum fraction, and the deactivated catalyst from the reactor is regenerated in regenerator and returned to the reactor for circular use. The said process can regenerate catalyst continuously or intermittently to maintain the catalytic activity of the alkylating catalyst for long period and has lowest loss of produce in amount and octane number while eliminating the thiofuran sulfur impurity in material.

Owner:CHINA PETROLEUM & CHEM CORP +1

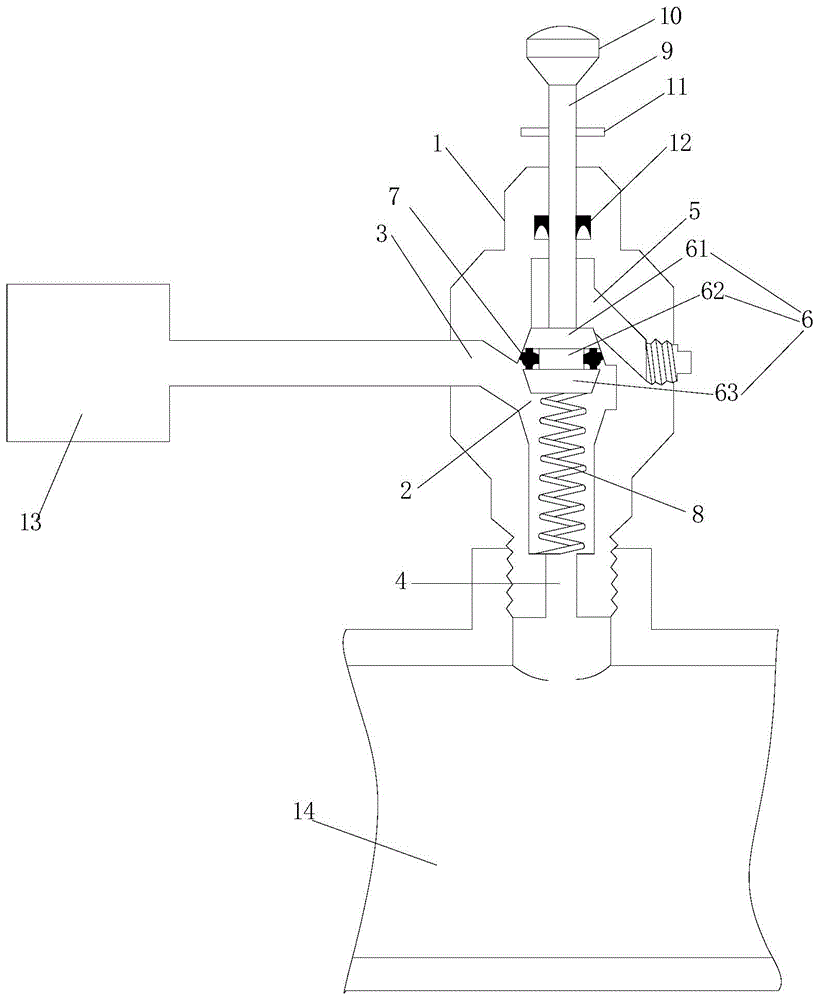

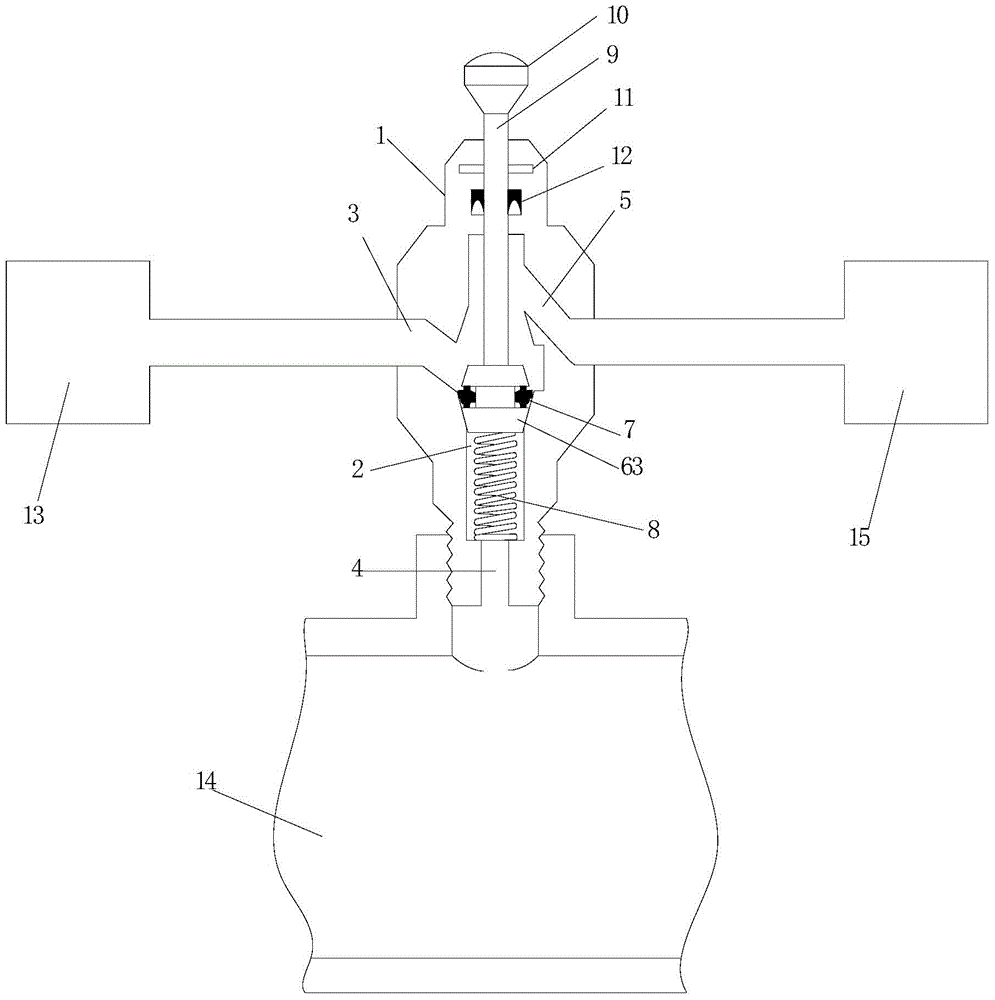

Three-way valve

InactiveCN104482246AOvercome the shortcoming of short lifeImprove sealingMultiple way valvesEngineeringMechanical engineering

Owner:TERRENCE ENERGY

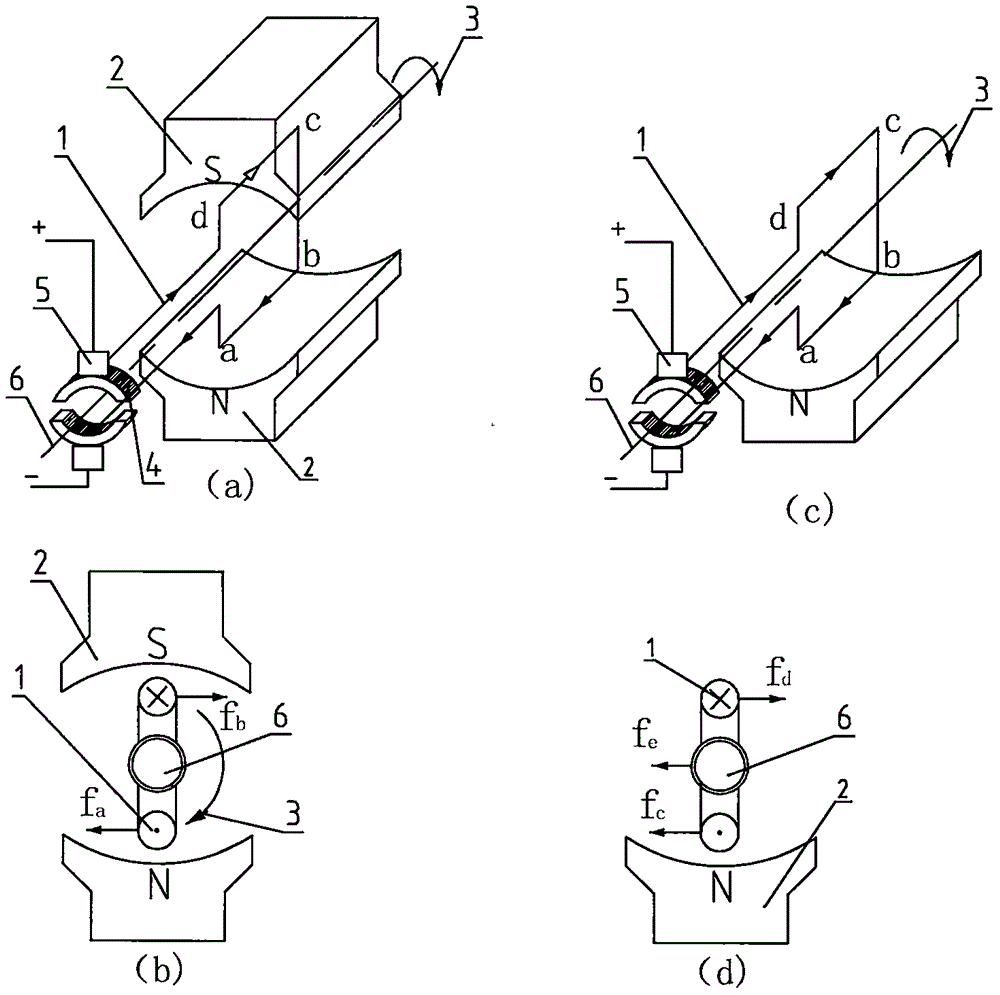

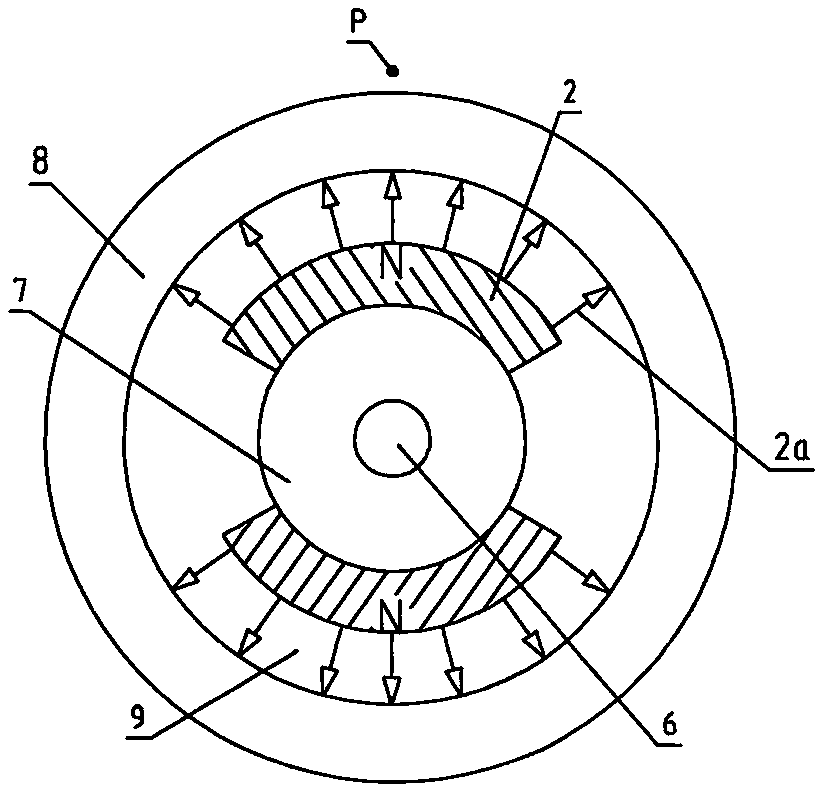

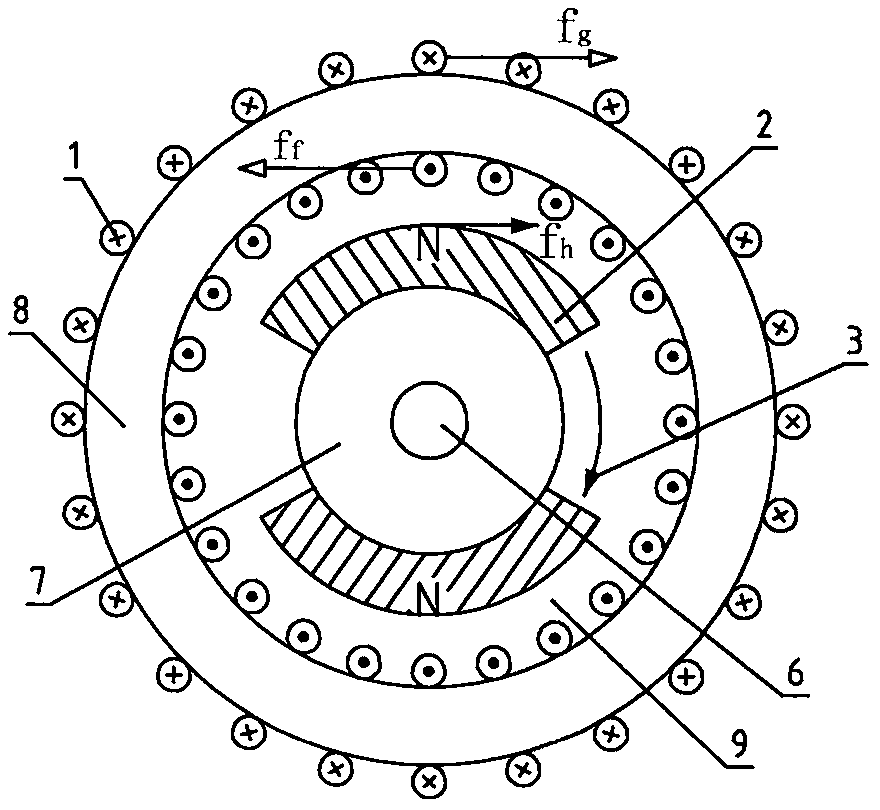

Design method of no-commutating permanent magnet direct current rotating motor

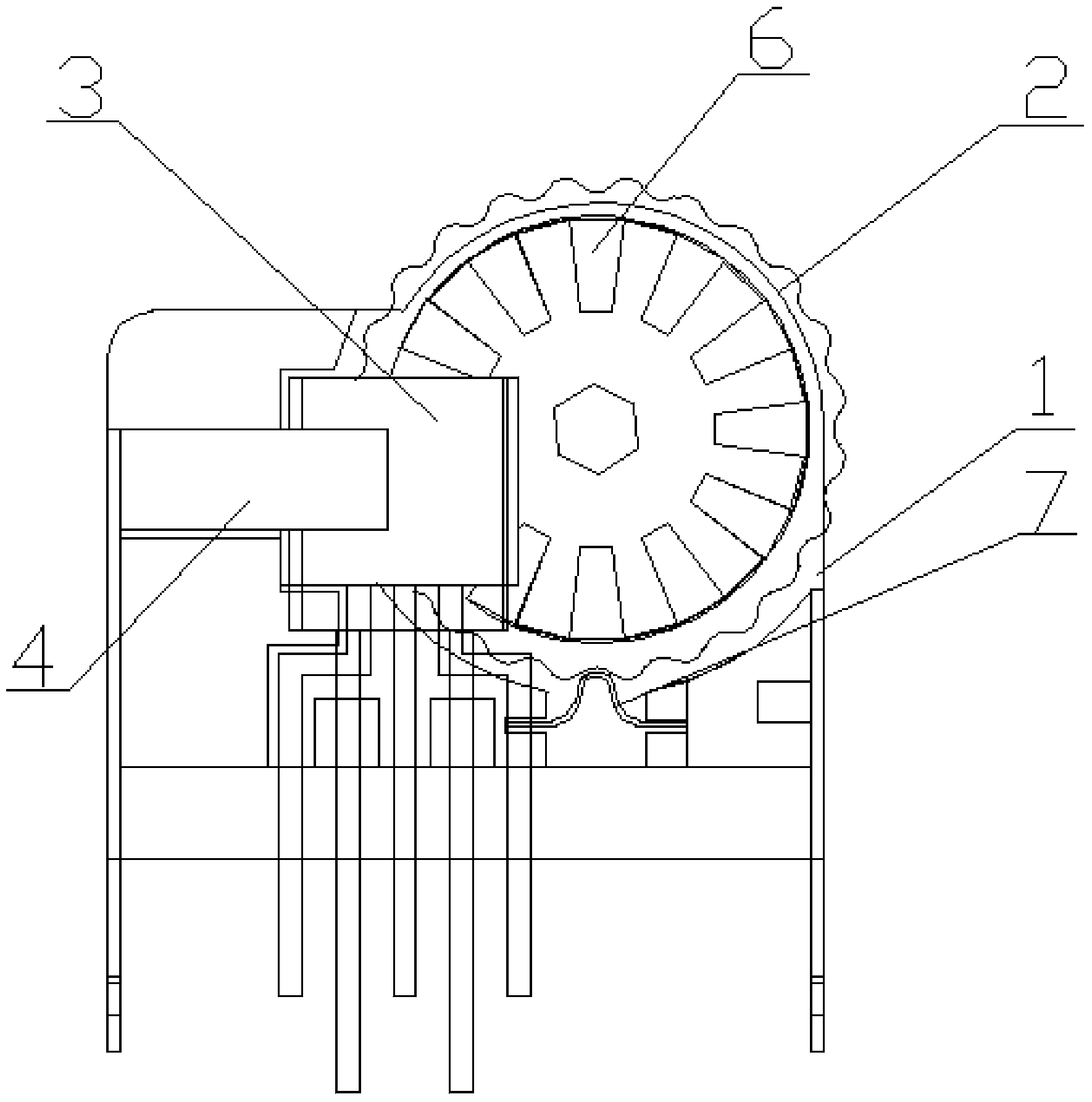

InactiveCN106712333APracticalEnables rotation workMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical conductorMagnetic poles

The invention discloses a design method of a no-commutating permanent magnet direct current rotating motor. The rotating motor is designed according to the principle that a current-carrying coil is subjected to ampere force in a magnetic field and a conductor cuts magnetic lines of force to generate induced electromotive force and the characteristic that a ferromagnet isolates and shields the magnetic field. By using the method, no matter the rotating motor is used as a direct current motor or a direct current generator, a commutating device is not needed; the rotating motor is mainly composed of a stator winding and rotor permanent magnets, and the stator winding is axially wound on the cylindrical wall of a cylindrical ferromagnet core; and the polar faces of the same magnetic poles of a plurality of permanent magnets on the rotor face the stator winding. The design method has the advantages: the permanent magnet direct current rotating motor does not need a commutating device, and the defect of shot service life of the direct current motor due to commutation is overcome; the requirement of a sensor and a supporting electronic element of a brushless direct current motor for the working environment is eliminated; and the permanent magnet direct current rotating motor has the advantages of simplicity in processing, low manufacturing cost, low fault rate and long service life.

Owner:丁士来

An energy-saving water-based coating that absorbs and degrades formaldehyde and releases negative oxygen ions

An energy-saving water-based coating adsorbing and degrading formaldehyde and releasing negative oxygen ions is characterized in that the energy-saving water-based coating is prepared from, by weight, at least 15-30 parts of hydroxyl water-based resin, 40-100 parts of a first packing and 5-25 parts of a second packing, wherein the first packing is one or more of diatomite, coarse whiting and ash calcium, and the second packing is selected from montmorillonite and / or sericite. The energy-saving water-based coating has good breathability, water resistance, formaldehyde degradation performance and other excellent performance and can be used on the basic layers and face layers of building walls.

Owner:XIAN TIJI BUILDING DECORATION MATERIAL CO LTD

Method for preparing polyformaldehyde dimethyl ether by catalytic distillation

ActiveCN102372615BOvercome the shortcoming of short lifeIncrease concentrationOrganic chemistryOrganic compound preparationRefluxReboiler

Owner:CHINA PETROLEUM & CHEM CORP +1

Resin trapper for nuclear power plant

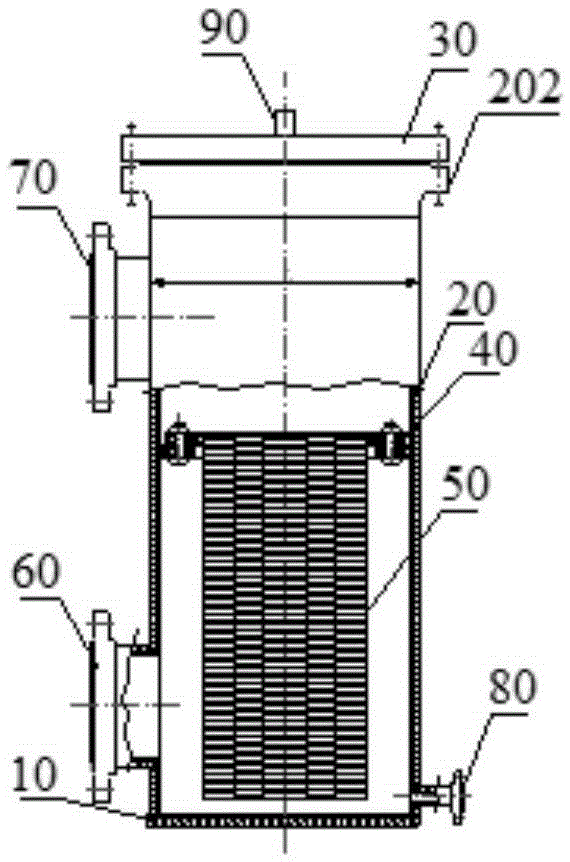

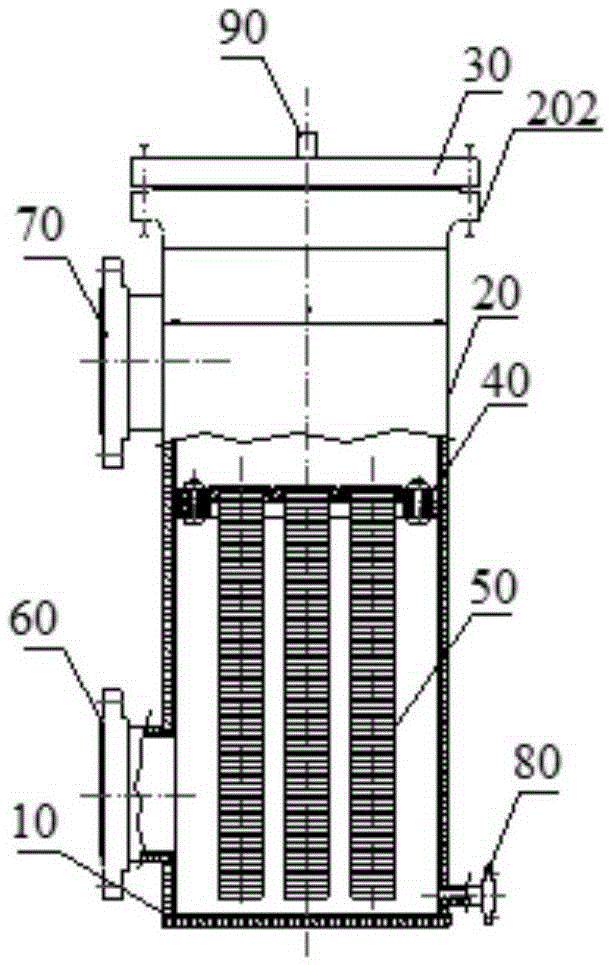

InactiveCN105355251ASo as not to damageLow costRadioactive decontaminationStationary filtering element filtersNuclear powerEngineering

The invention discloses a resin trapper for a nuclear power plant. The resin trapper comprises a bottom plate, a cylinder arranged on the bottom plate, a manhole cover plate assembled on the cylinder, a filter element mounting porous plate arranged in the cylinder, a filter element positioned in the cylinder by virtue of the filter element mounting porous plate, and a water inlet and a water outlet which are formed in the side wall of the cylinder, wherein the bottom plate, the cylinder, the manhole cover plate, the water inlet and the water outlet are manufactured by bimetallic composite steel plates; the inner layer refers to stainless steel plates; the outer layer refers to vessel steel plates; and the filter element mounting porous plate and the filter element are made of all stainless steel. According to the resin trapper for the nuclear power plant disclosed by the invention, the bimetallic composite steel plates are adopted, a layer of thin stainless steel plates is compounded on the inner side of an equipment container, the original rubber lined layer is replaced, and the defect that the rubber lined layer is short in service life is overcome. Compared with an all stainless steel material, the material in the invention has the advantages that the construction cost is greatly reduced, and the anticorrosion requirement is met. In the nuclear power plant operating process, the resin trapper for the nuclear power plant disclosed by the invention does not need to be maintained and replaced in the unit lifecycle under the normal use condition.

Owner:中广核工程有限公司 +1

Co-culturing method of human primary hepatocytes and liver nonparenchymal cells

ActiveCN103509751BAchieve in vitro expansionNo blocking operation requiredArtificial cell constructsVertebrate cellsCulture fluidSeparation technology

Owner:康珞生物科技(常州)有限公司

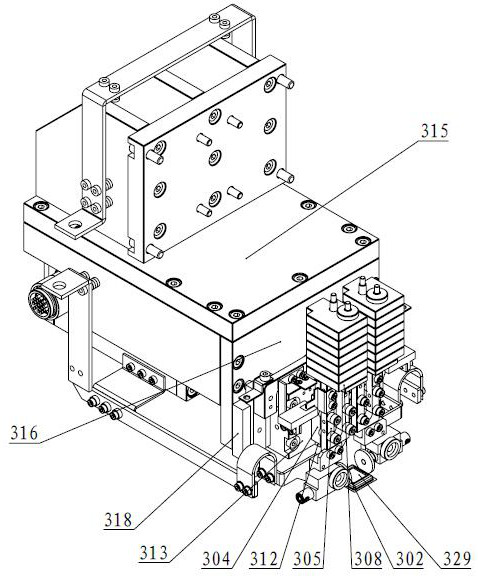

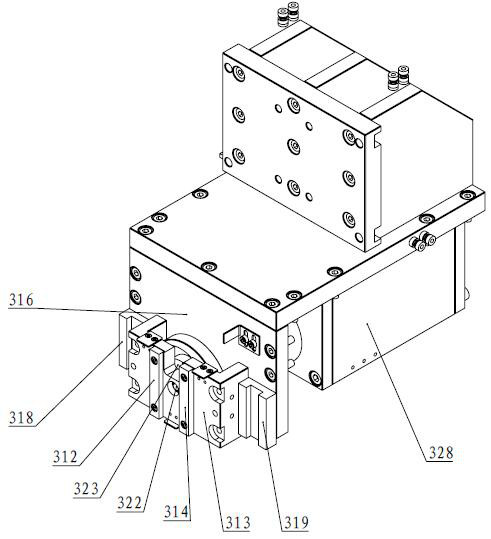

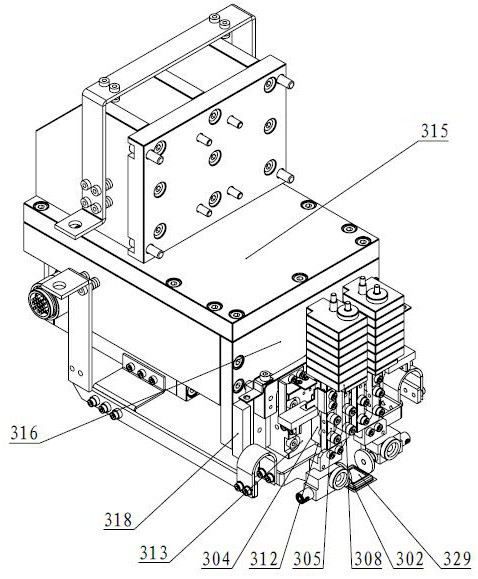

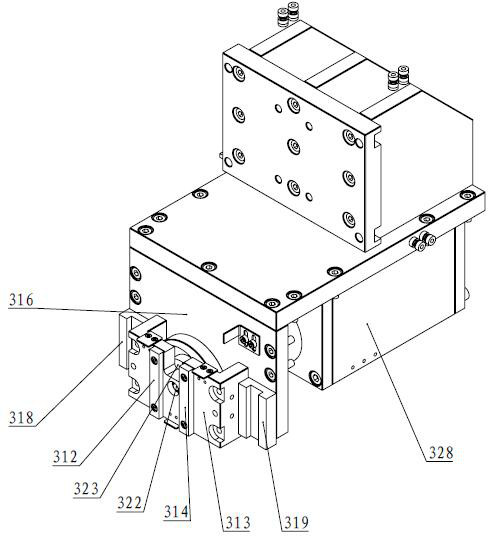

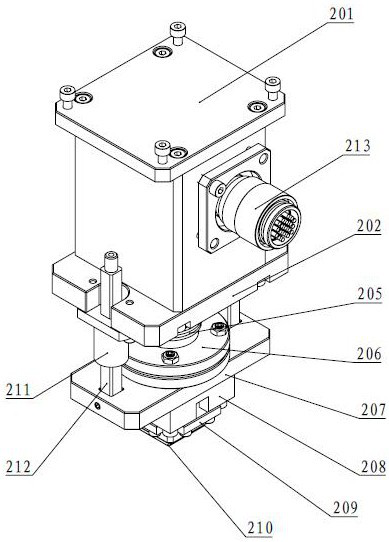

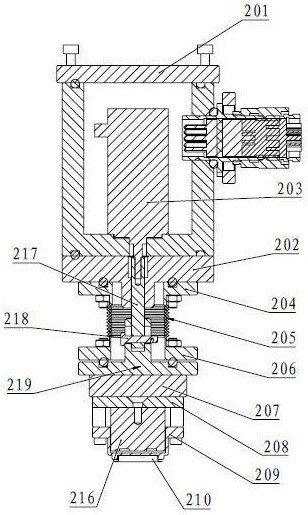

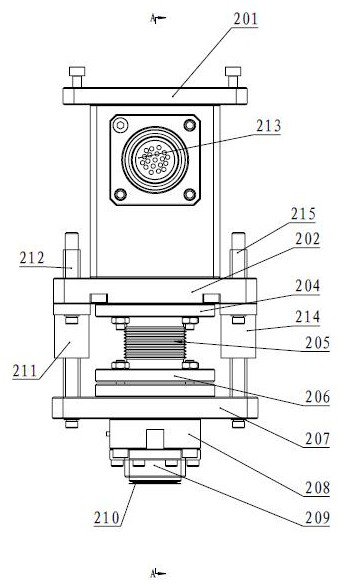

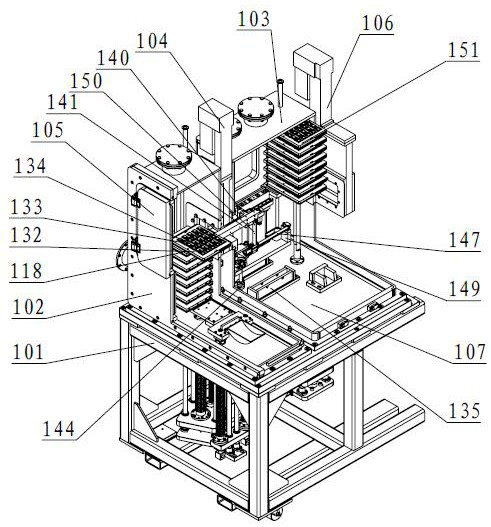

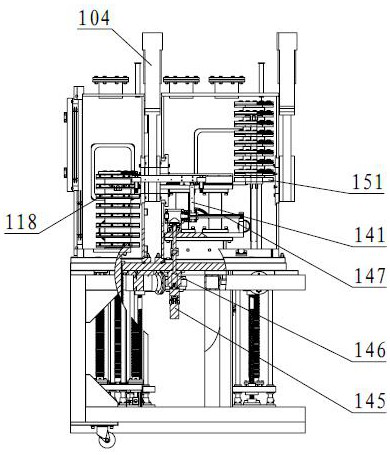

Self-adaptive parallel sealing and welding mechanism for microelectronic packaging in high vacuum state

PendingCN114074916ALow investment costOvercome the shortcoming of short lifeDecorative surface effectsWelding/cutting auxillary devicesThin shellsWeld seam

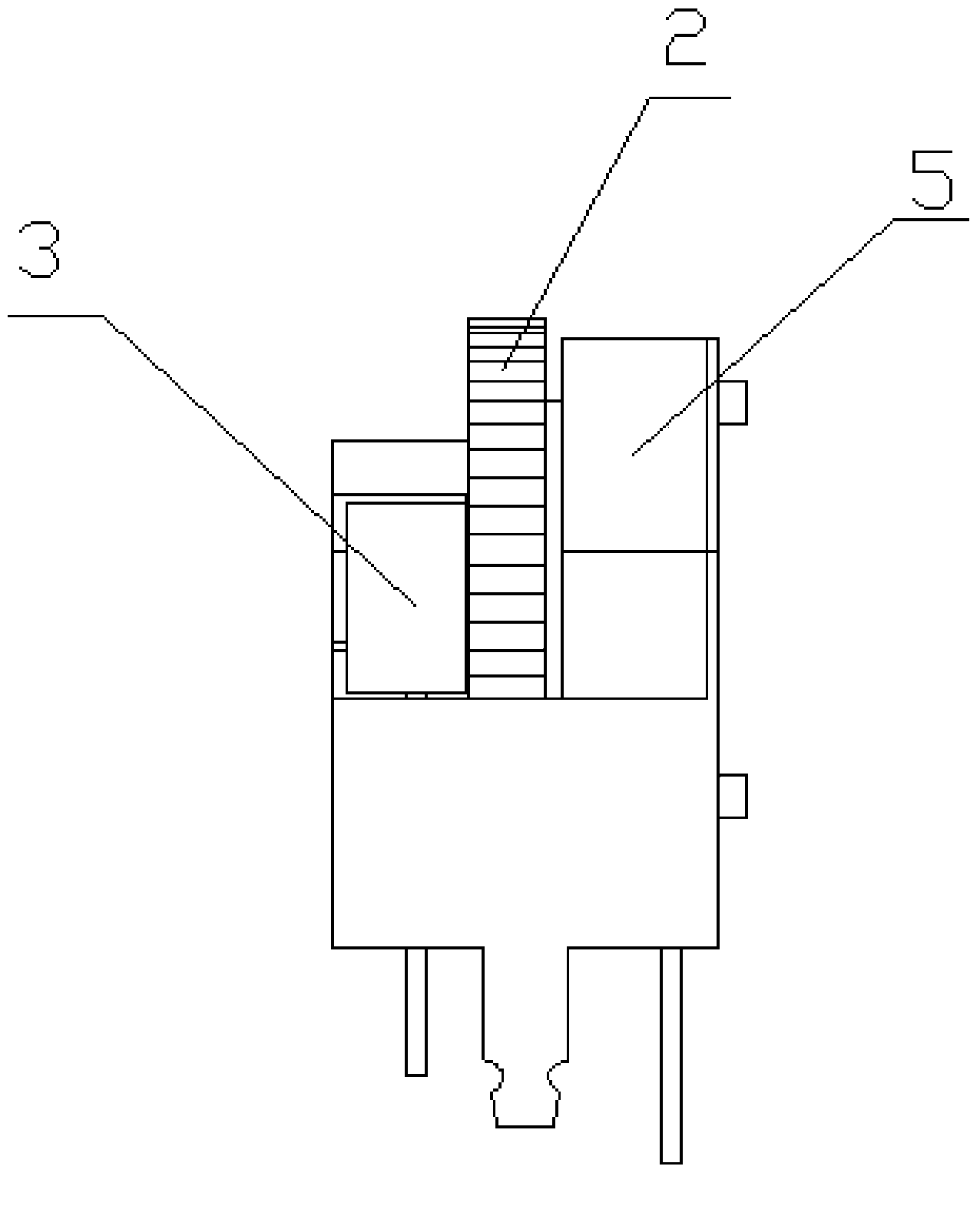

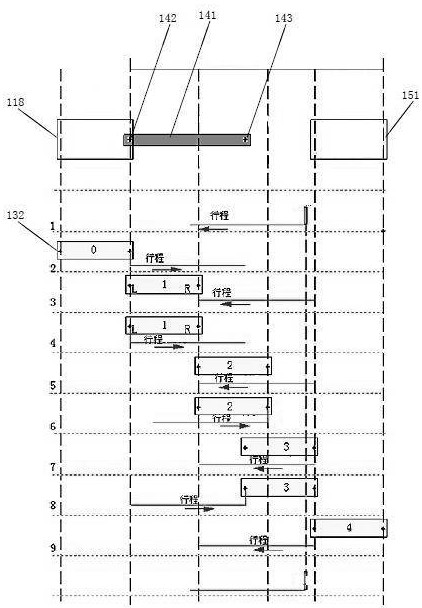

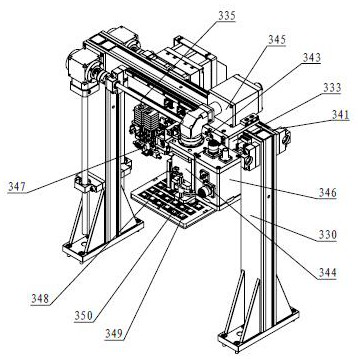

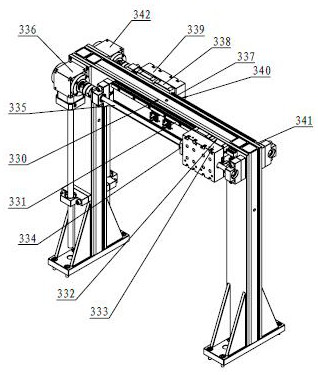

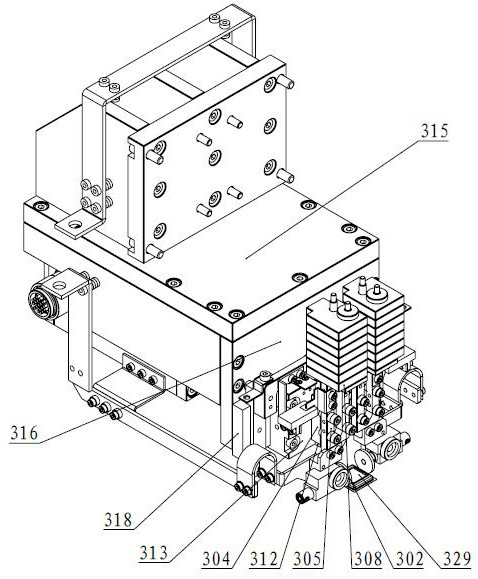

The invention discloses a self-adaptive parallel sealing and welding mechanism for microelectronic packaging in a high vacuum state, and solves the problem of how to complete high-quality parallel sealing and welding of a cover plate and a tube shell of a thin-shell device in a vacuum environment at low cost so as to improve the sealing and welding yield. The self-adaptive parallel sealing and welding mechanism is characterized in that a floating parallel welding wheel support is arranged, two parallel welding wheels on the support are pressed on parallel welding seams between a cover plate and a tube shell in a floating mode, weights are arranged at the top end of the parallel welding wheel support, and the welding pressure of the parallel welding wheels on the welding seams is adjusted by increasing or reducing the number of the weights, so that the adjustment of the self-adaptive welding pressure in the welding process is realized; and a shoulder-pole-shaped semi-square-shaped jacking frame body is arranged between the left parallel welding wheel support and the right parallel welding wheel support, the floating parallel welding wheel support is lifted and lowered through jacking connection of eccentric wheels to the semi-square-shaped jacking frame body, and conversion between the welding state and the to-be-welded state of the two parallel welding wheels is completed. The sealing and welding quality of the packaging assembly is greatly improved.

Owner:西北电子装备技术研究所

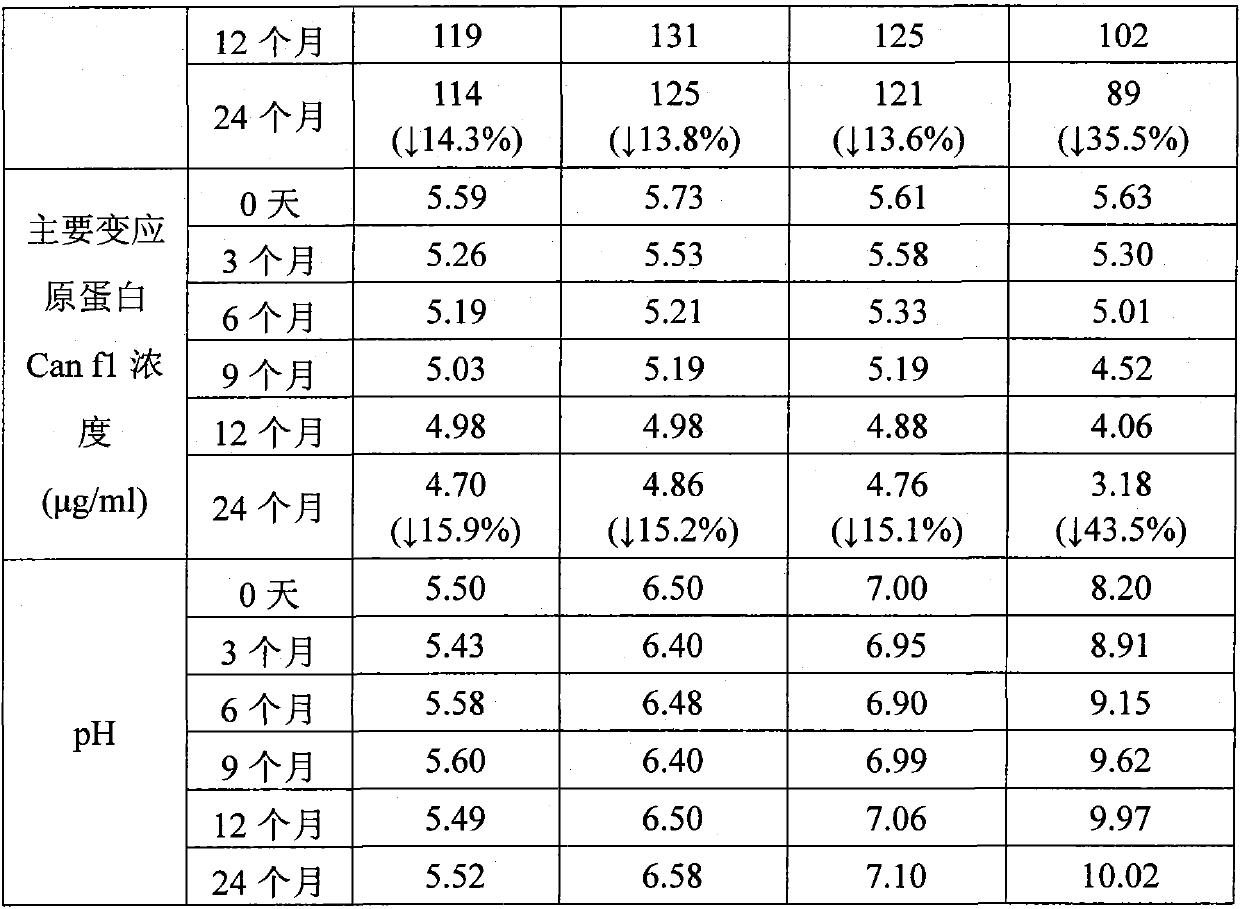

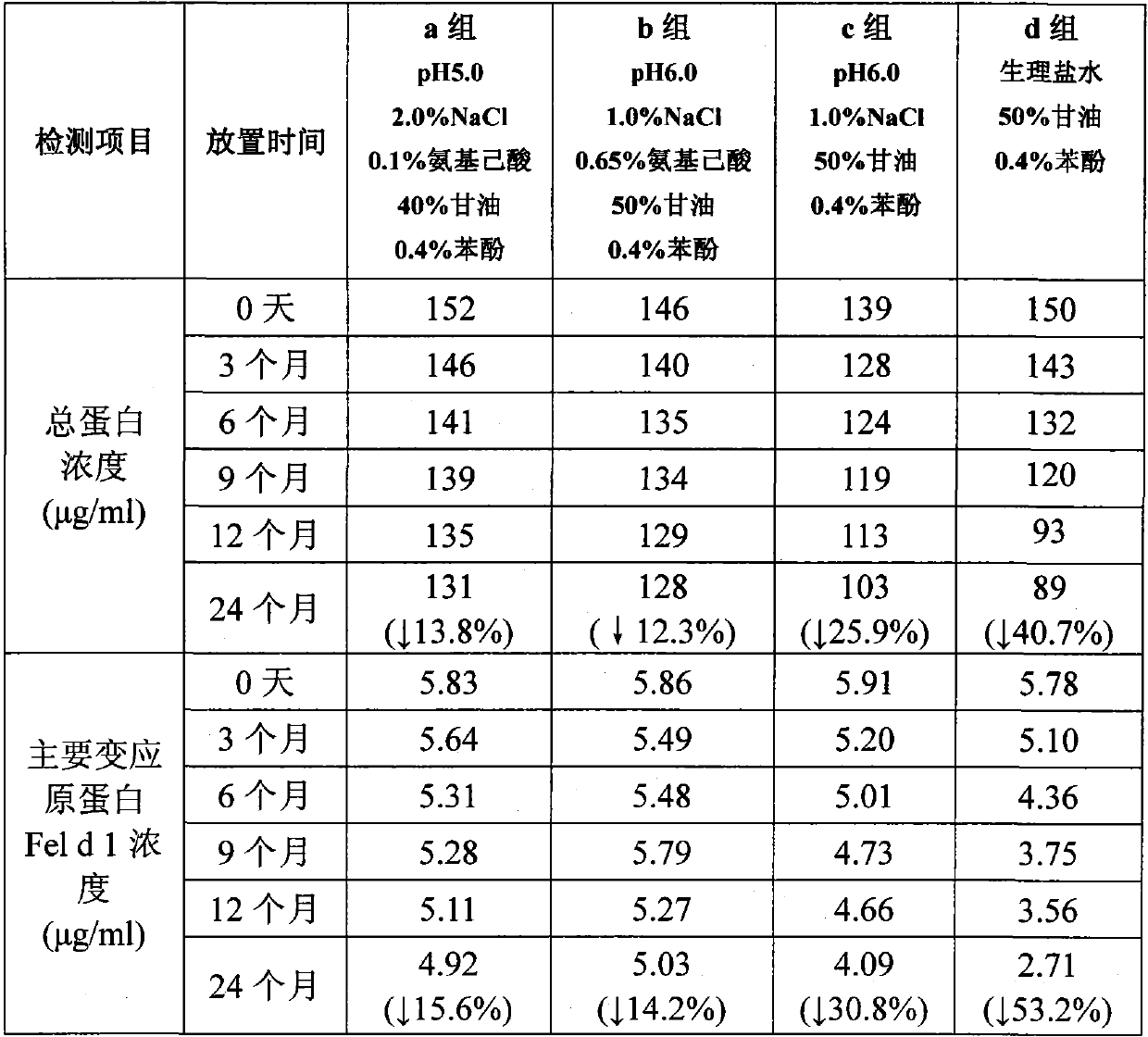

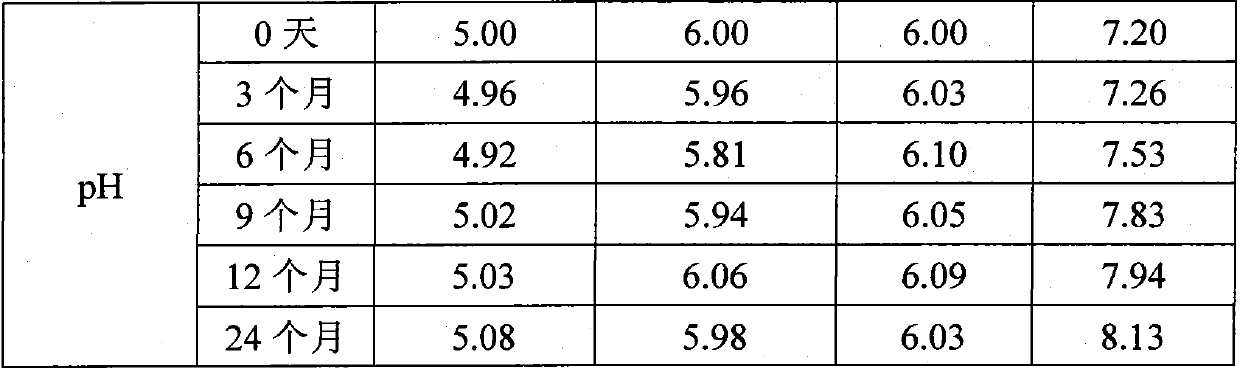

A stable liquid pharmaceutical composition containing animal dander allergen

ActiveCN104491858BImprove stabilityOvercome the shortcoming of short lifeAllergen ingredientsImmunological disordersDiseaseDolichol

The present invention provides a stable liquid pharmaceutical composition containing animal dander allergen. The liquid pharmaceutical composition comprises a therapeutically effective amount or a diagnostically effective amount of animal dander allergens, an effective buffering amount of a pH 5.0-7.0 buffer, aminocaproic acid with a concentration range of 0.1%-2.0% w / v, Polyols and pharmaceutical preservatives in concentrations ranging from 30% to 70% v / v. The liquid pharmaceutical composition can be made into dosage forms such as oral, subcutaneous injection, sublingual, aerosol, nasal cavity, skin pricking, etc., and can be applied to the diagnosis or treatment of allergies induced by animal dander allergens disease.

Owner:ZHEJIANG WOLWO BIOTECH

Flexible picking method of thin-shell device cover plate picking mechanism in high vacuum state

ActiveCN114212539ALow investment costOvercome the shortcoming of short lifeLoading/unloadingConveyor partsElectric machineStructural engineering

The invention discloses a flexible picking method of a thin-shell device cover plate picking mechanism in a high vacuum state. The flexible picking method solves the problems of how to finish accurate picking of a thin-shell device cover plate in a vacuum environment and how to ensure that the cover plate is not deformed due to impact force in the putting-down process. The floating thin-shell cover plate picking die is connected to the downward output shaft of the linear motor, and the contact impact force between the picking die and the picked thin-shell cover plate is overcome through floating fit between the shaft end of the downward output shaft of the linear motor and the shaft end sleeve; a corrugated pipe sleeve is arranged at the lower end of a sealing cavity of the floating pickup die and the linear motor, so that secondary absorption of contact impact force is realized; besides, the square prismatic column guide rod is arranged between the picking die and the sealing cavity of the linear motor, so that the picking die is effectively prevented from rotating when picking the thin-shell cover plate, the picking positioning accuracy is greatly improved, and a positioning foundation is laid for follow-up processes.

Owner:西北电子装备技术研究所

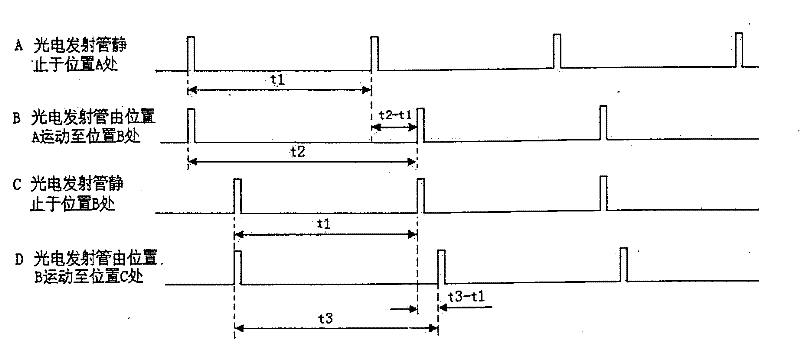

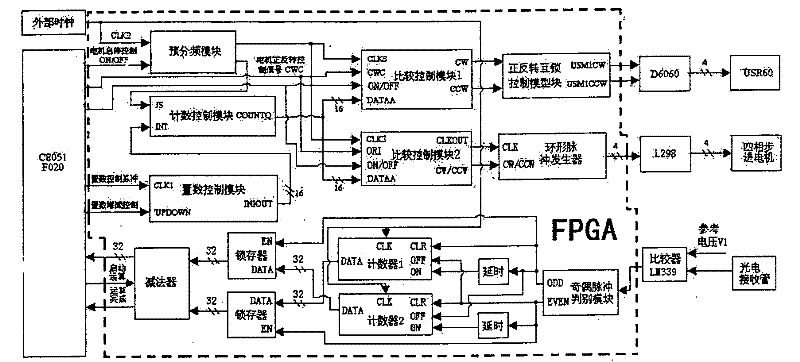

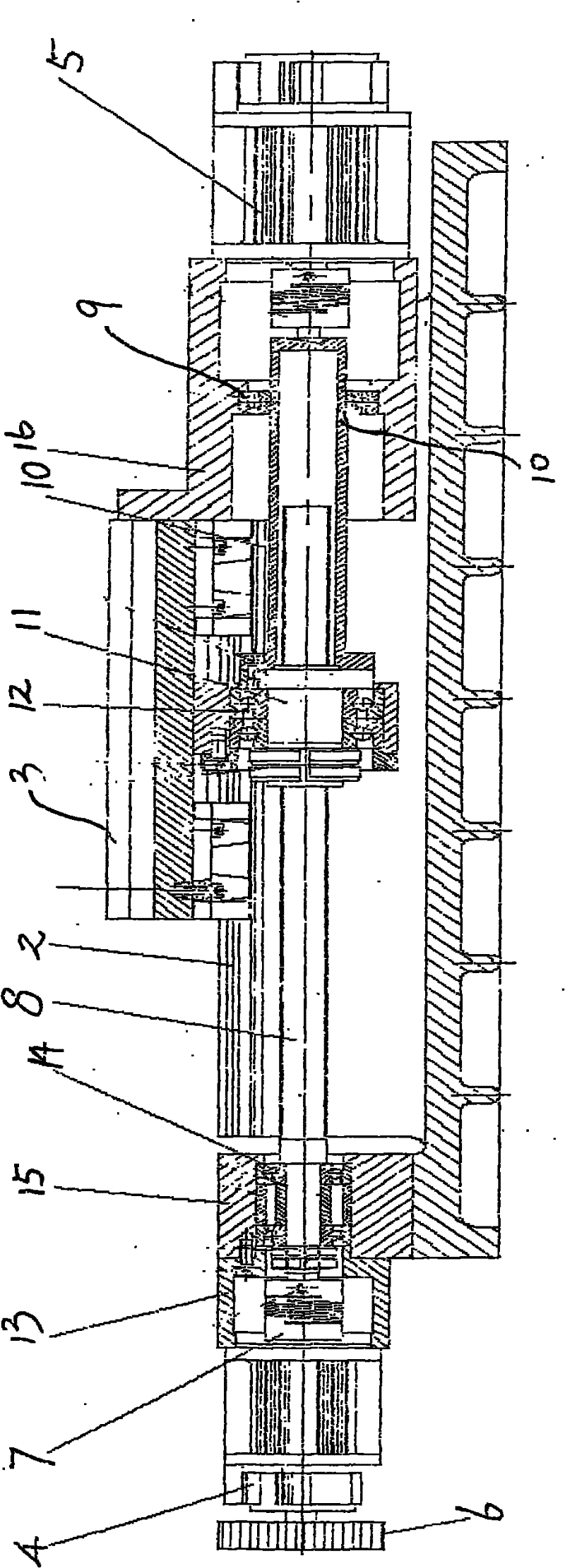

Hybrid drive semi-closed loop precision positioning system

InactiveCN101820203BOvercome the shortcoming of short service lifeReasonable structurePiezoelectric/electrostriction/magnetostriction machinesElectric motor speed/torque regulationMotor driveMeasurement device

The invention discloses a combined drive semi-closed loop precision positioning system for double-motor undisturbed switchover, comprising a sliding table base, wherein a linear slide rail is mounted on the sliding table base and is provided with a sliding table, the left side and the right side of the linear slide rail are respectively provided with an ultrasound wave motor driving the sliding table to move on the slide rail and a stepping motor, and the ultrasound wave motor is connected with a corner measurement device. The invention has reasonable structure, overcomes the disadvantage of short service life of the ultrasound wave motor and can realize double-motor undisturbed switchover during precision positioning process.

Owner:NANTONG UNIVERSITY

Method for making thermal insulation and decorative ceramic tiles

ActiveCN105819826BOvercome the shortcoming of short lifeReduce production processCeramic materials productionCeramicwareBrickThermal insulation

The invention relates to the technical field of construction materials, and discloses a manufacturing method of a thermal insulation decorative ceramic brick. The manufacturing method comprises the following steps: spraying demoulding paint on a heatproof plate or placing heatproof paper on the heatproof plate; forming a decorative layer on the demoulding paint or the heatproof paper; covering a combination layer on the decorative layer, evenly spraying foamed ceramic powder on the combination layer; sintering and moulding. According to the manufacturing method, the foamed ceramic powder and decorative layer are sintered at a high temperature together so as to integrate the foamed ceramic powder and decorative layer, the steps are reduced, and the manufacturing cost is reduced therefore.

Owner:四会市金丽阳新材料有限公司

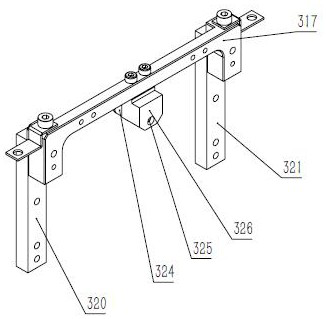

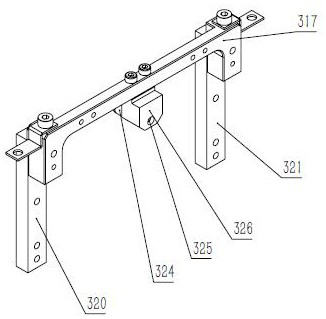

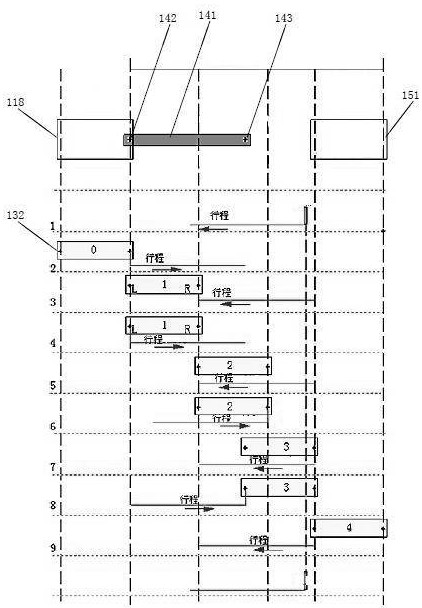

Tray transfer method for microelectronic packaging assembly between high-vacuum sealed cavities

ActiveCN114074828ATransport stableOvercome the shortcoming of short lifeFinal product manufactureMechanical conveyorsRobotic armElectric machine

The invention discloses a tray transfer method for a microelectronic packaging assembly between high-vacuum closed cavities. The problem of how to complete tray transfer in a limited space by adopting a simple and economical driving mechanism is solved. A gate valve is arranged between two high vacuum chambers for microelectronic packaging assembly tray transfer, a transfer mechanism is arranged in a second activated process chamber, and a driving motor of the transfer mechanism is arranged outside the process chamber, so that the independent sealing performance of the process chamber is ensured, and meanwhile, the stable and reliable movement of the tray is realized due to good guidance; compared with a vacuum motor, the driving motor reducer adopts a common motor, so that the cost is reduced and the service life is prolonged; besides, the length of a mechanical arm is shortened, the intermittent segmented conveying of the trays is achieved through reciprocating work of the mechanical arm, and the purpose of reducing the occupied space of the tray transferring mechanism is achieved; the process cavity is independent, the transfer of the high-vacuum trays is achieved, and the driving structure is simple, economical, reliable and durable.

Owner:西北电子装备技术研究所

Petroleum fraction alkyl sulfur transferring method

InactiveCN1195825COvercome the shortcoming of short lifeKeep aliveRefining with solid acidsDistillates petroleumAlkyl transfer

The present invention is petroleum fraction alkyl sulfur transferring method. Heated petroleum fraction and alkylating agent are made to enter movable catalyst reactor, so that the sulfide in petroleum fraction and the alkylating agent produce alkylation reaction under the action of powdered alkylating catalyst. The reaction products are separated to obtain low-sulfur light petroleum fraction and high--sulfur heavy petroleum fraction, and the deactivated catalyst from the reactor is regenerated in regenerator and returned to the reactor for circular use. The said process can regenerate catalyst continuously or intermittently to maintain the catalytic activity of the alkylating catalyst for long period and has lowest loss of produce in amount and octane number while eliminating the thiofuran sulfur impurity in material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Microelectronic packaging assembly tray transfer mechanism between high-vacuum sealed cavities

PendingCN114074829AOvercome high costTo overcome the short life of the motorMechanical conveyorsDrive motorTransfer mechanism

The invention discloses a microelectronic packaging assembly tray transfer mechanism between high-vacuum sealed cavities, and solves the problem of how to complete tray transfer by adopting a simple and economical driving mechanism in a limited space. A gate valve is arranged between two high vacuum chambers for microelectronic packaging assembly tray transfer, a transfer mechanism is arranged in a second activated process chamber, and a driving motor of the transfer mechanism is arranged outside the process chamber, so that the independent sealing performance of the process chamber is ensured, and meanwhile, the stable and reliable movement of the tray is realized due to good guidance; compared with a vacuum motor, the driving motor reducer adopts a common motor, so that the cost is reduced and the service life is prolonged; besides, the length of a mechanical arm is shortened, the intermittent segmented conveying of the trays is achieved through reciprocating work of the mechanical arm, and the purpose of reducing the occupied space of the tray transferring mechanism is achieved; the process cavity is independent, the transfer of the high-vacuum trays is achieved, and the driving structure is simple, economical, reliable and durable.

Owner:西北电子装备技术研究所

Production method of polyoxymethylene dimethylether

ActiveCN102372614BOvercome the shortcoming of short lifeHigh selectivityOrganic chemistryOrganic compound preparationPolyoxymethyleneReflux

The invention relates to a production method of polyoxymethylene dimethylether and mainly solves the problems of low selectivity of polyoxymethylene dimethylether, complex technology and high energy consumption during the present production process of polyoxymethylene dimethylether. The production method provided by the invention comprises the following steps of: carrying out a reaction between methylal and trioxane in a catalytic distillation column while separating ingredients, condensing steam on the top of the column, followed by reflux, allowing a first part of the materials on the bottom of the column to return to the catalytic distillation column after vaporizing the first part through a reboiler while a second part is used as a production stream I and the weight ratio of the first part materials to the second part materials is 1-10: 1; allowing the production stream I to enter into a divided wall distillation column for separation, and collecting polyoxymethylene dimethylether DMM3-8 from the produced central part in the divided wall distillation column. The technical scheme provided by the invention greatly solves the problems and can be used in the industrial production of polyoxymethylene dimethylether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Automatic alignment parallel seal welding method for microelectronic packaging in high vacuum state

PendingCN114212753ALow investment costOvercome short lifeDecorative surface effectsChemical vapor deposition coatingWeld seamThin shells

The invention discloses an automatic alignment parallel seal welding method for microelectronic packaging in a high vacuum state, and solves the problem of how to complete high-quality parallel seal welding of a cover plate and a tube shell of a thin-shell device at low cost in a vacuum environment. A floating parallel welding wheel support is arranged, two parallel welding wheels on the support are pressed on parallel welding seams between a cover plate and a tube shell in a floating mode, weights are arranged at the top end of the parallel welding wheel support, and the welding pressure of the parallel welding wheels on the welding seams is adjusted by increasing or reducing the number of the weights. The adjustment of self-adaptive welding pressure in the welding process is realized; a shoulder-pole-shaped semi-square-shaped jacking frame body is arranged between a left parallel welding wheel support and a right parallel welding wheel support, the floating parallel welding wheel supports are lifted and lowered through jacking connection of an eccentric wheel to the semi-square-shaped jacking frame body, a tray conveying driving motor is installed outside a closed cavity, and conveying of trays in the cavity is completed at low cost; and the cover plate and the tube shell can be accurately aligned.

Owner:西北电子装备技术研究所

Preparation method for polyoxymethylene dimethyl ether

ActiveCN102372612BImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationRefluxReboiler

The invention relates to a preparation method for polyoxymethylene dimethyl ether, which mainly solves the problem that the trioxymethylene conversion rates and the selectivity of DMM3 to 8 are low in the production of polyoxymethylene dimethyl ether at present. Methylal and trioxymethylene are adopted to react under effective reaction conditions in a catalytic distillation tower, component separation is carried out during reaction, part of condensed overhead vapour flows back, the other part is recovered, the overhead reflux ratio is 1 to 10, distillate returns into the tower, part of bottom material is vaporized by a reboiler and then returns into the catalytic distillation tower, the rest is adopted as recovered liquid, wherein the methylal, the trioxymethylene and the returning distillate enter between the two reaction sections of the catalytic distillation tower, and the catalyst in the catalytic distillation tower is heterogeneous acidic catalyst. The technical scheme effectively solves the problem, and can be used in the industrial production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing polyformaldehyde dimethyl ether

ActiveCN102372613BImprove conversion rateHigh selectivityOrganic chemistryOrganic compound preparationReboilerCatalytic distillation

The invention relates to a method for producing polyformaldehyde dimethyl ether. By the method, the problems of a low conversion rate of trioxymethylene and low selectivity of poly methoxyl dimethyl ether (DMM3-8) in the production of the polyformaldehyde dimethyl ether at present are mainly solved. In the method, methanol and the trioxymethylene are separated while reacting in a catalytic distillation tower under the effective reaction condition, steam on a tower top is refluxed after being condensed, a first part of materials at a tower bottom is vaporized by a reboiler and returns to the catalytic distillation tower, a second part of the materials is used as extraction liquid, and a mass ratio of the first part to the second part is (1-15):1, wherein the trioxymethylene enters the catalytic distillation tower from the tower top, the methanol can enter the catalytic distillation tower from a stripping section to any position on the tower top, and a catalyst in the catalytic distillation tower is a heterogeneous acidic catalyst. Through the technical scheme, the problems are better solved. The method can be used for the industrial production of the polyformaldehyde dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com