Resin trapper for nuclear power plant

A technology of resin traps and nuclear power plants, which is applied in nuclear engineering, chemical instruments and methods, fixed filter elements, etc., can solve the problems of large construction impact, short service life of the rubber lining layer, and shortened service life of the rubber lining, etc., to achieve The effect of low installation and operation requirements, low ambient temperature requirements, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

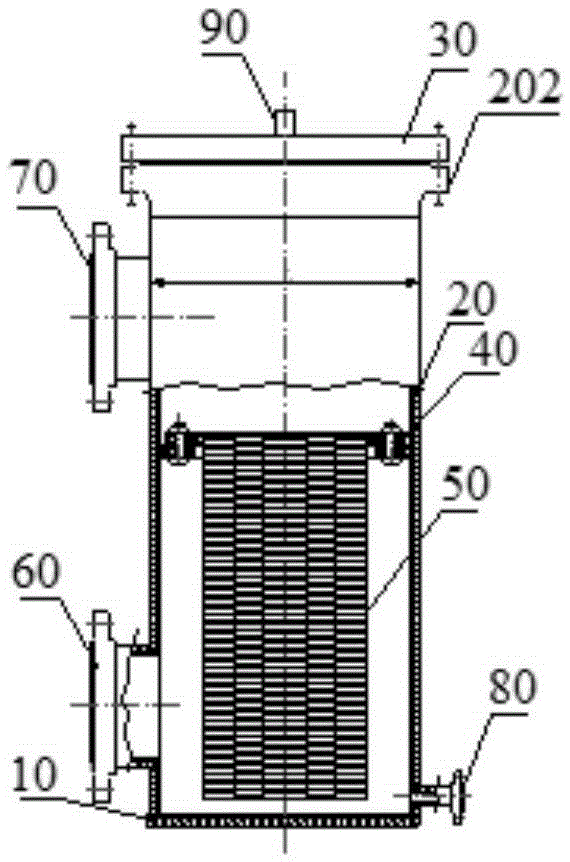

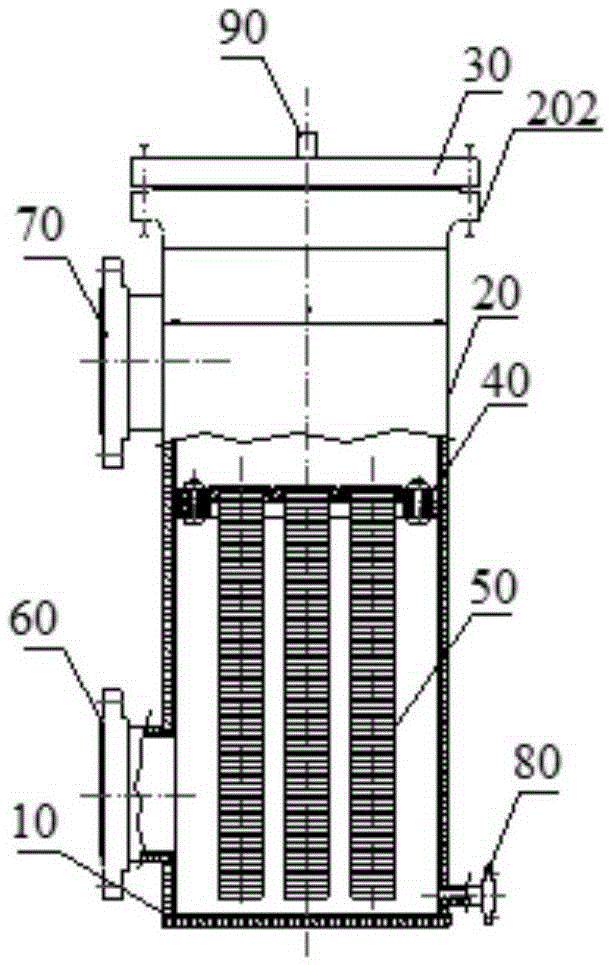

[0030] see figure 1 As shown, the resin catcher for nuclear power plants of the present invention is a first embodiment of a high-flow medium-pressure resin catcher comprising: a bottom plate 10, a cylinder 20 installed on the bottom plate 10, and a manhole flange 202 assembled on the cylinder 20 The manhole cover plate 30 on the top, the filter element installation perforated plate 40 arranged in the cylinder body 20 and the filter element 50 positioned in the cylinder body 20 through the filter element installation perforated plate 40, and the water inlet 60 arranged on the side wall of the cylinder body 20 And water outlet 70.

[0031] exist figure 1 In the illustrated embodiment, the bottom plate 10, the cylinder body 20, the manhole cover plate 30, the water inlet 60 and the water outlet 70 are made of bimetal composite steel plates. The inner wall of the composite steel plate is made of thinner stainless steel plate that meets the anti-corrosion requirements, the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com