Tray transfer method for microelectronic packaging assembly between high-vacuum sealed cavities

A technology of microelectronic packaging and closed cavity, which is applied in transportation and packaging, conveyors, mechanical conveyors, etc., to overcome high cost, simple driving structure, and reduce space size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below in conjunction with accompanying drawing:

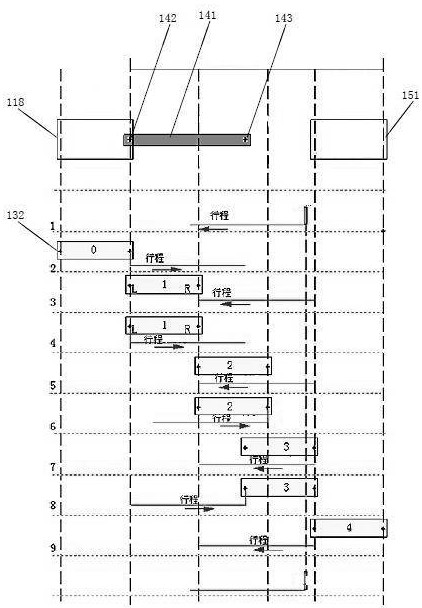

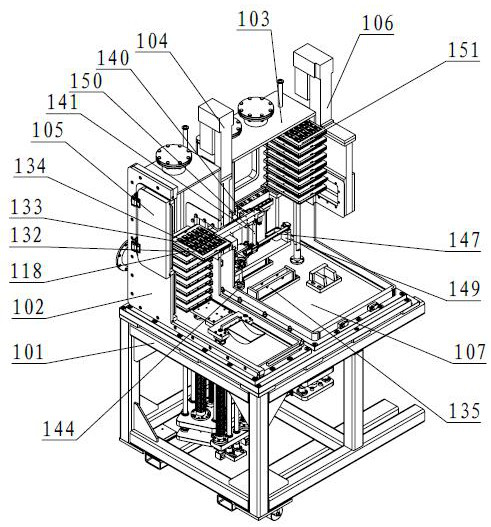

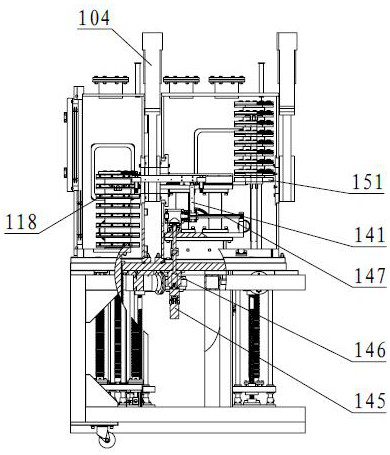

[0028] A microelectronic packaging assembly tray transfer mechanism between high-vacuum airtight chambers, including a box-shaped frame base 101, a worktable 107 is arranged on the top of the box-shaped frame base 101, and the worktable 107 is adjacent to and independent of each other A baking airtight cavity 102 and an activation airtight cavity 103 are arranged respectively. Between the baking airtight cavity 102 and the activation airtight cavity 103, a communication gate valve 104 connecting the two chambers is arranged. 102 is provided with a loading door 105 on the left side facade, and is provided with a second door valve 106 on the right side facade of the activated airtight cavity 103, and is respectively provided with a transfer screw support frame 149 and Lead screw drive motor reducer 144, between transmission drive lead screw support frame 149 and lead screw drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com