Self-adaptive parallel sealing and welding mechanism for microelectronic packaging in high vacuum state

A technology of microelectronic packaging and parallel sealing and welding, which is applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., to achieve self-adaptation, overcome short life, and save investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail below in conjunction with accompanying drawing:

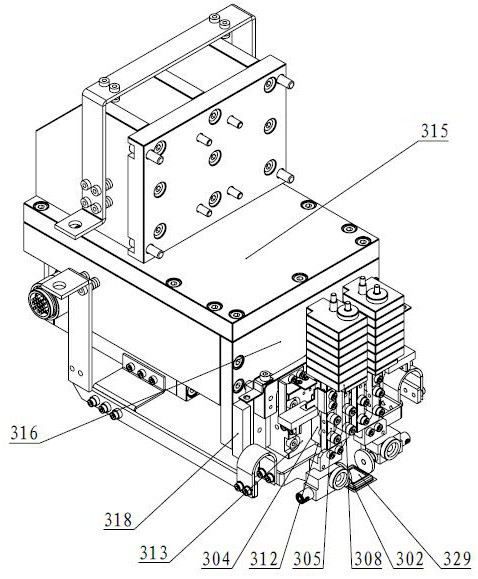

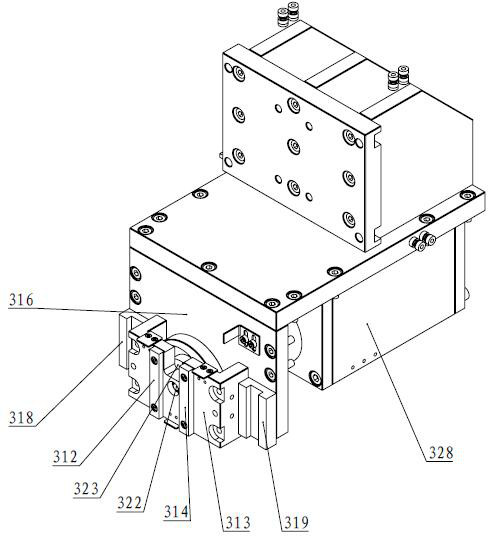

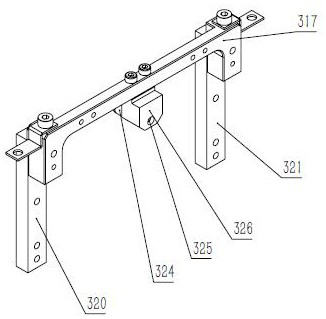

[0020] A self-adaptive parallel sealing and welding mechanism for microelectronic packaging in a high vacuum state, comprising a high vacuum airtight chamber, in which a box-shaped frame body 315 is arranged, and in front of the front side vertical plate 316 of the box-shaped frame body 315 On the facade, an eccentric wheel 323 is provided, and an airtight casing 328 of an eccentric wheel driving motor is arranged in the box-shaped frame body 315, and an eccentric wheel driving motor is arranged in the airtight casing 328, and a Air, the output shaft of the eccentric wheel drive motor, after passing through the sealed magnetic fluid, is connected together with the eccentric wheel shaft 322 of the eccentric wheel 323; a U-shaped frame plate 313 is buckled on the front facade of the front side vertical plate 316, and the eccentric wheel 323 is movably arranged in the framework o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com