Flexible picking method of thin-shell device cover plate picking mechanism in high vacuum state

A high-vacuum, thin-shell technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., to save investment costs, realize economy and durability, and overcome the effects of short life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

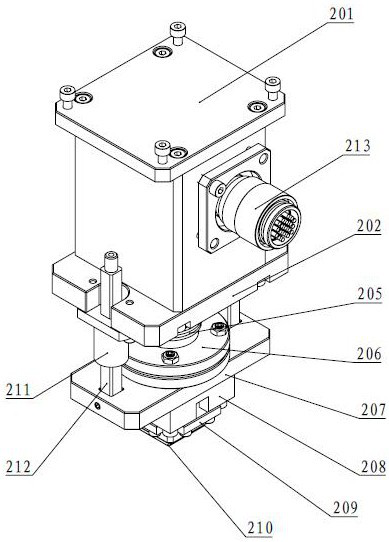

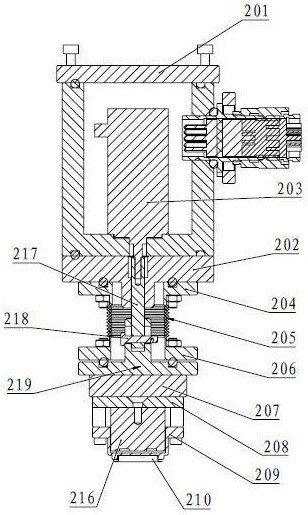

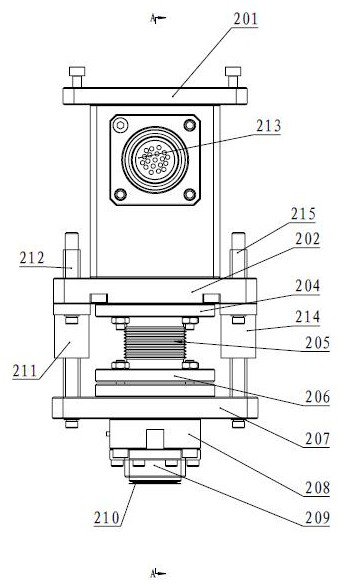

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

[0023] A combined pick-up mechanism for thin-shell devices and covers in a high-vacuum state, including a high-vacuum cavity, a tray is arranged on a workbench in the high-vacuum cavity, and a cover for thin-shell devices 210 is arranged in the tray. In the high vacuum cavity directly above the cover plate 210 of the shell device, a linear motor sealing chamber 201 is fixedly arranged. The linear motor sealing chamber 201 is fixedly arranged on the linear motor sealing chamber mounting plate 202. The linear motor 203, the output shaft 217 of the linear motor 203 passes downwards to the below of the linear motor sealing chamber mounting plate 202; just below the output shaft 217 of the linear motor 203, an electromagnet mounting box hanging plate 207 is arranged, At the center of the top surface of the electromagnet installation box suspension plate 207, a shaft end sleeve 219 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com