Petroleum fraction alkyl sulfur transferring method

A technology for petroleum distillate and alkylation sulfur, which is applied in the petroleum industry, refining hydrocarbon oil, refining with solid acid, etc., and can solve problems such as short lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

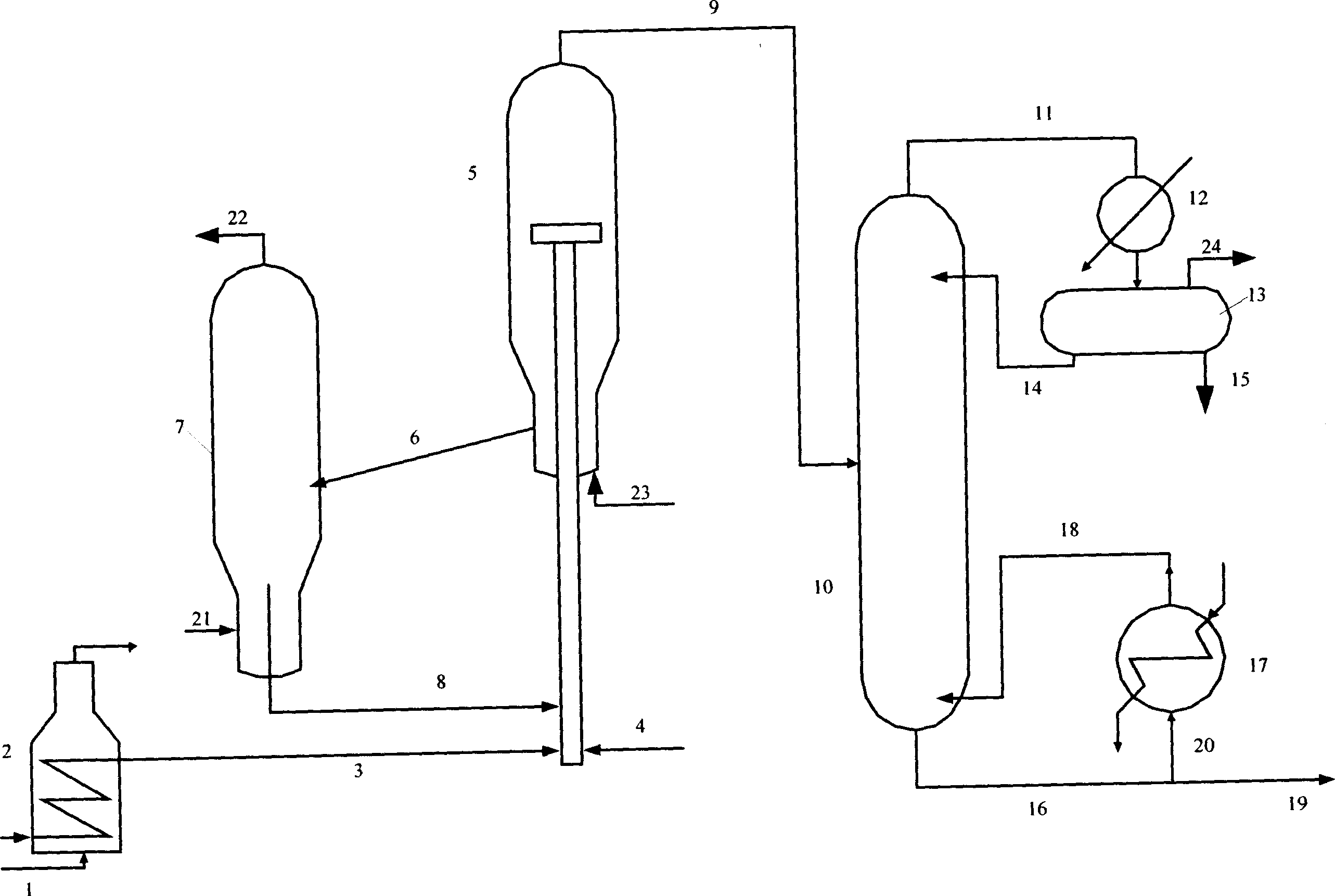

[0010] The method provided by the invention is specifically implemented as follows: the alkylating agent and the petroleum fraction raw material are premixed in a weight percentage of 0.1 to 99.9, preferably 5 to 45, and then enter the catalyst movable reactor, and the sulfide and alkane in the petroleum fraction are The alkylating agent is in contact with the powdered alkylation catalyst at a temperature of 35°C to 400°C, preferably 90°C to 280°C, a pressure of 0.001MPa to 8MPa, preferably 0.2MPa to 4MPa, and a space velocity of 1h -1 ~4h -1 The alkylation reaction is carried out under certain conditions. At the same time, the alkylating agent can be superimposed to form a component with a higher octane number. The sulfide reacts with the alkylating agent to form a sulfide with a higher boiling point. The reaction product enters the distillation tower Distillation is carried out, the low-sulfur light petroleum fraction is distilled from the top of the tower, and the heavy pet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com