Method for preparing polyformaldehyde dimethyl ether by catalytic distillation

A technology of polyoxymethylene dimethyl ether and catalytic distillation, which is applied in chemical instruments and methods, preparation of organic compounds, chemical industry, etc., can solve the problem of low selectivity, improve conversion rate and selectivity, promote reaction, increase effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

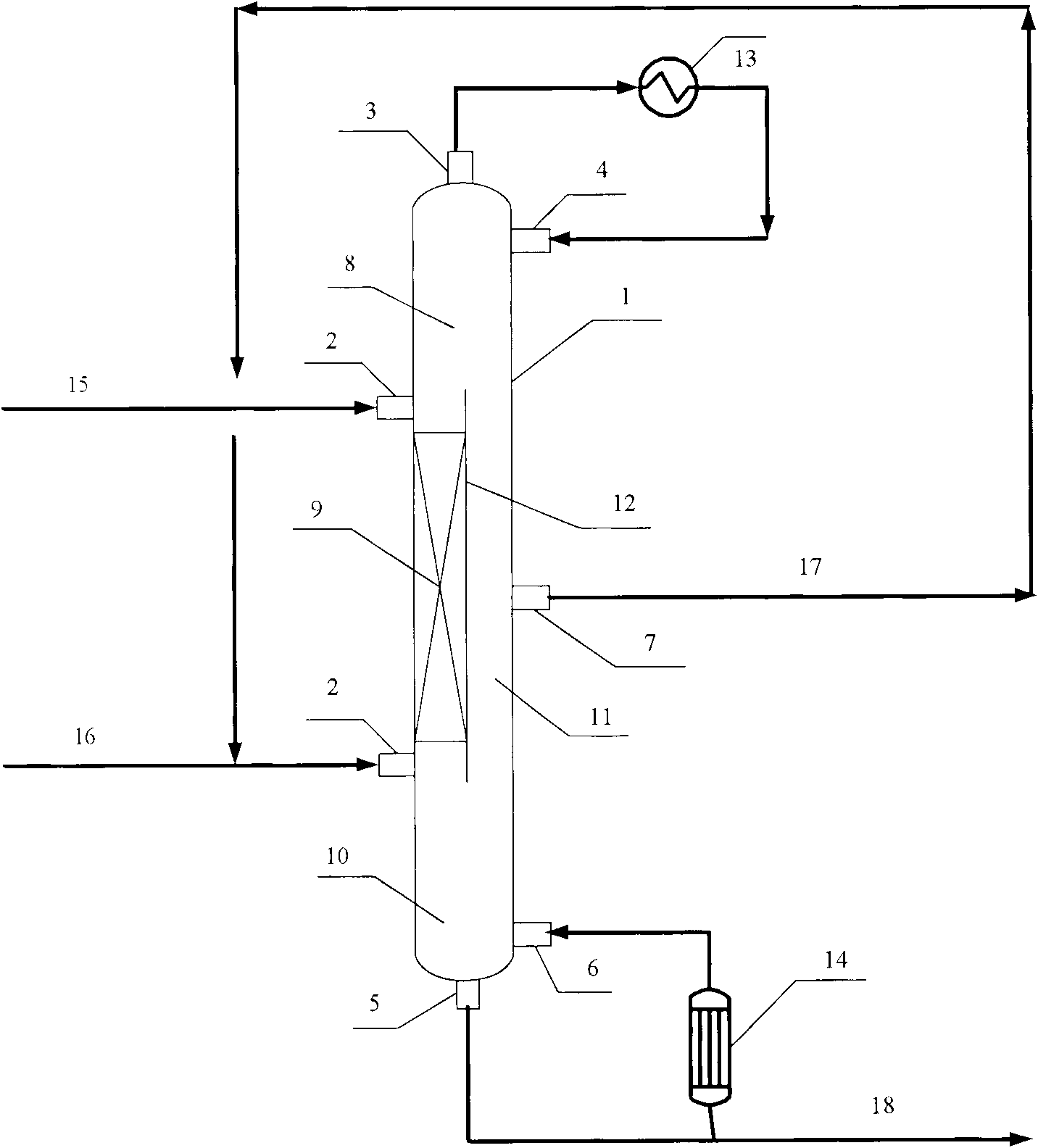

[0014] according to figure 1 The process for preparing polyoxymethylene dimethyl ether by catalytic distillation is shown, the operating pressure of the catalytic distillation tower is 0.5MPa, the number of theoretical plates in the public rectification section is 20, the number of theoretical plates in the public stripping section is 20, and the separation efficiency of the reaction section is equivalent to the number of theoretical plates is 30, and the number of theoretical plates in the rectifying section on the production side is 30. The catalyst is SAPO-34 molecular sieve, paraformaldehyde enters the first theoretical plate of the reaction section at a flow rate of 2 g / min (counting from top to bottom, the same below), and methylal enters from the bottom of the reaction section at a flow rate of 1 g / min. Enter, total reflux at the top of the tower, the control tower kettle does not contain polyoxymethylene dimethyl ether DMM 3~8 , the temperature of the catalytic reacti...

Embodiment 2~5

[0016] Other conditions are the same as in Example 1, except that the type of catalyst is changed, and the catalyst is Su Qing brand 001×4 strong acid resin, ZSM-5, SO 4 -2 / Fe 2 o 3 , Cl -1 / TiO 2 and SO 4 -2 / Fe 2 o 3 , Catalytic distillation results are shown in Table 1.

Embodiment 6

[0018] according to figure 1 As shown, the operating pressure of the catalytic distillation tower is 4.0MPa, the number of theoretical plates in the public rectification section is 5, the number of theoretical plates in the common stripping section is 5, the separation efficiency of the reaction section is equivalent to the number of theoretical plates being 5, and the number of theoretical plates in the production side rectification section is 5. The number of theoretical boards is 5. The catalyst is MCM-22 molecular sieve, paraformaldehyde enters the first theoretical plate of the reaction section at a flow rate of 1 g / min and methylal at a flow rate of 10 g / min, the top of the tower is fully refluxed, and the control tower does not contain paraformaldehyde dimethyl Ether DMM 3~8 , the temperature of the catalytic reaction section is 180-200°C, and the catalytic distillation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com