Hybrid drive semi-closed loop precision positioning system

A precise positioning and hybrid drive technology, applied in control systems, electric components, generators/motors, etc., can solve the problems of short service life of ultrasonic motors, and achieve the effect of overcoming short service life, high resolution and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

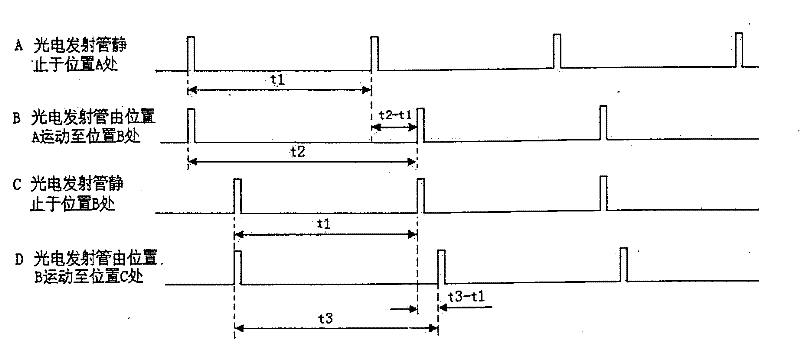

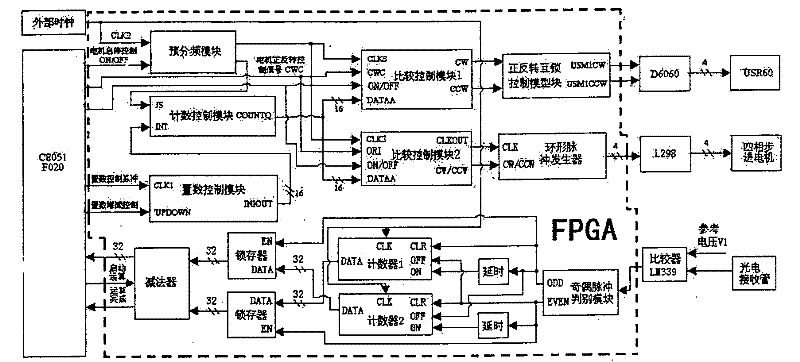

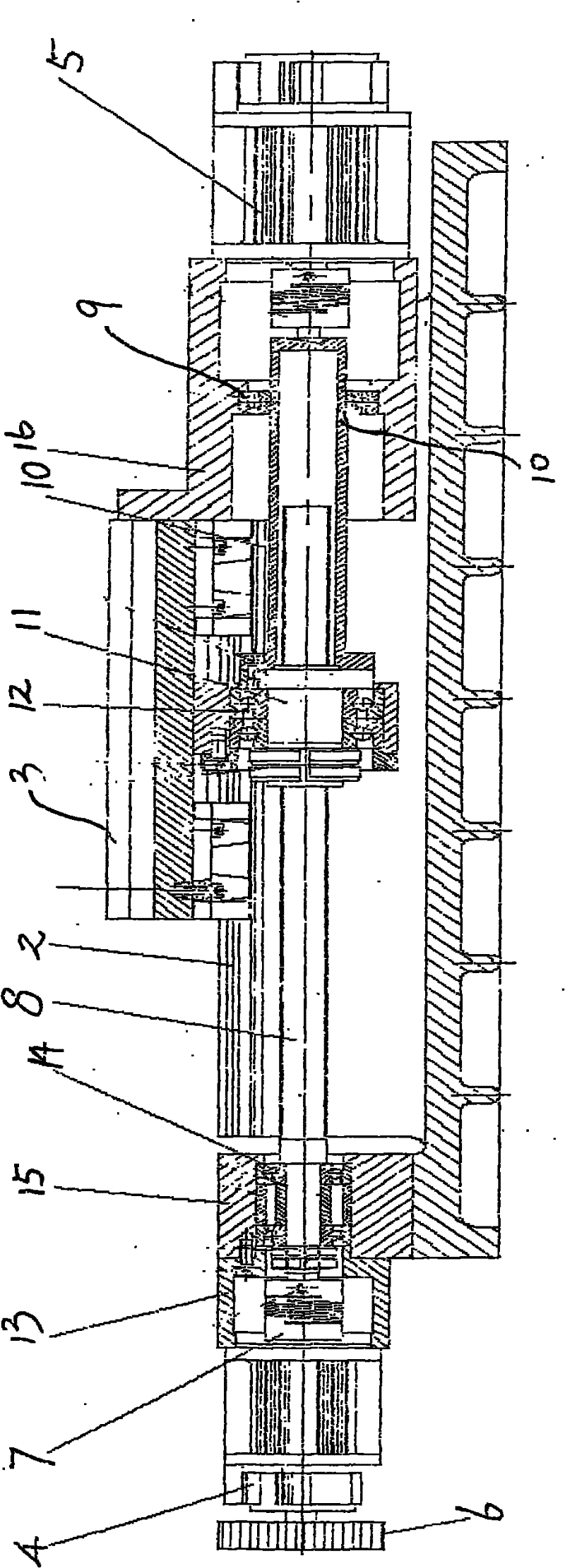

[0026] A mixed-drive semi-closed-loop precision positioning system, comprising a slide table base 1, a linear slide guide rail 2 mounted on the slide table base, a slide table 3 mounted on the linear slide guide rail, drive slide tables are respectively arranged on the left and right sides of the linear slide guide rail on the slide guide rail The moving ultrasonic motor 4 and the stepper motor 5 are connected with the angular position measuring device 6 .

[0027] The ultrasonic motor is connected to the ball screw 8 connected to the slide table through the first elastic diaphragm coupling 7, and the ball nut 11 is mounted on the ball screw; The shaft coupling 10 is connected, the shaft coupling is connected with the ball nut 11, the ball nut is fixedly connected with the nut seat through two angular contact bearings 12 with the same height of the inner and outer rings, the nut seat is fixedly connected with the sliding table 3, and is positioned by the positioning pin.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com