Energy-saving water-based coating adsorbing and degrading formaldehyde and releasing negative oxygen ions

A water-based coating, adsorption and degradation technology, applied in the direction of coating, etc., can solve the problems of poor water resistance, poor air permeability, non-environmental protection, etc., achieve breathability, humidity control, water resistance, reduce construction waste, and overcome short life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

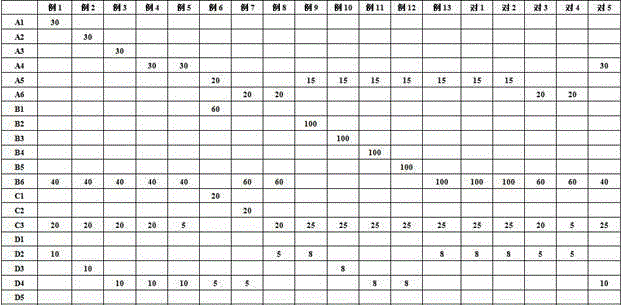

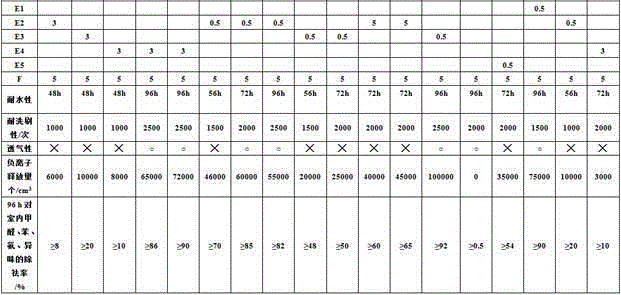

Examples

preparation example Construction

[0094] A second aspect of the present invention relates to providing the aforementioned method for preparing an energy-saving water-based paint that absorbs and degrades formaldehyde and releases negative oxygen ions, and is characterized in that it comprises the following steps:

[0095] Step 1, adding the hydroxyl-type water-soluble resin into deionized water, heating and stirring until the hydroxyl-type water-soluble resin is completely dissolved, cooling to room temperature, and filtering to obtain a hydroxyl-type water-soluble resin solution;

[0096] Step 2, mix and stir the deionized water and additives evenly, add the first filler, the second filler, and negative ion powder, mix under the action of a high-speed mixer, and grind it into a pigment slurry;

[0097] Step 3: Add the above-mentioned pigment slurry into the hydroxyl-type water-soluble resin solution, adjust the pH to 7-8, heat and stir, mix evenly, filter through a filter, remove impurities, and dry to obtain ...

Embodiment 1

[0110] An energy-saving water-based paint that absorbs and degrades formaldehyde and releases negative oxygen ions. The energy-saving water-based paint at least includes 15-30 parts by weight of a hydroxyl-type water-soluble resin, 40-100 parts by weight of a first filler, 5-25 parts by weight Parts of second filler, the first filler is selected from one or more of diatomite, heavy calcium, lime calcium, and the second filler is selected from montmorillonite and / or sericite.

[0111] The hydroxy-type water-soluble resin is selected from one of hydroxycellulose, polyvinyl alcohol, and hydroxyacrylic acid.

[0112] The hydroxyl type water-soluble resin is selected from polyvinyl alcohol.

[0113] The degree of alkalization of the polyvinyl alcohol polyvinyl alcohol is greater than or equal to 60 mol%, and the weight average molecular weight is 1000-10000.

[0114] The first filler is selected from one or more of diatomaceous earth, heavy calcium, and lime calcium.

[0115] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com