Device and method for producing aged asphalt for testing

A technology of aged asphalt and production method, which is applied in the field of road engineering test, can solve the problems of long heating time, slow speed of aged asphalt, troublesome operation, etc., and achieve the effect of increasing the amount of one-time aging, increasing the aging speed, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

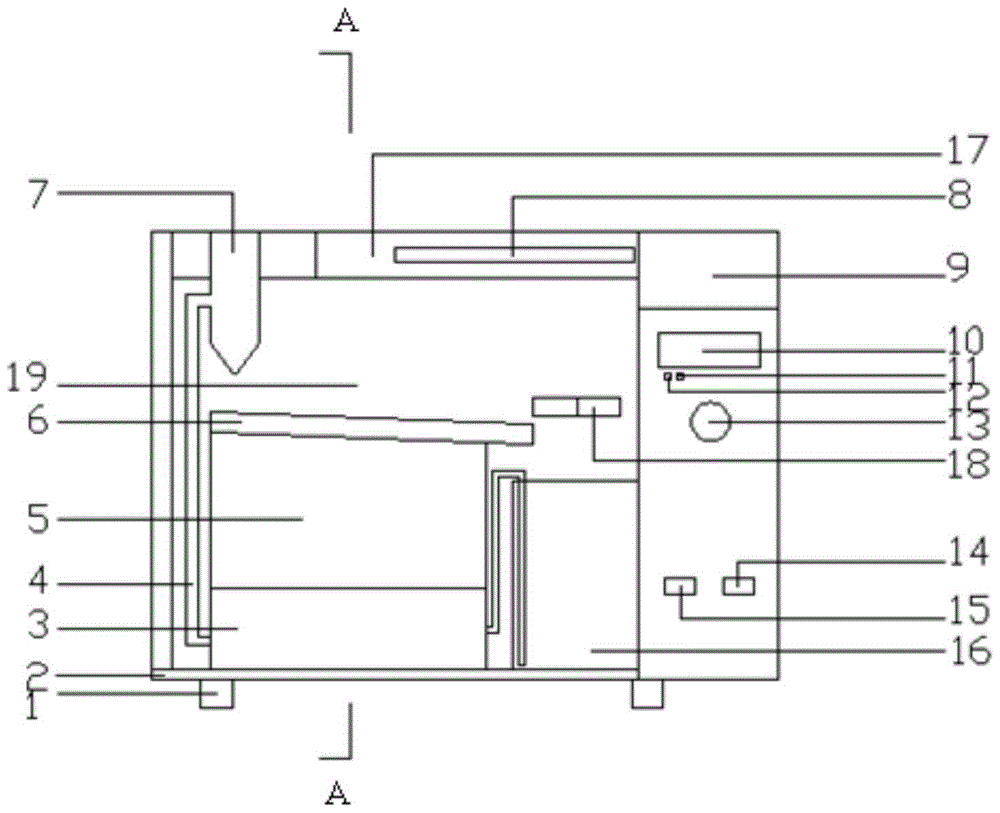

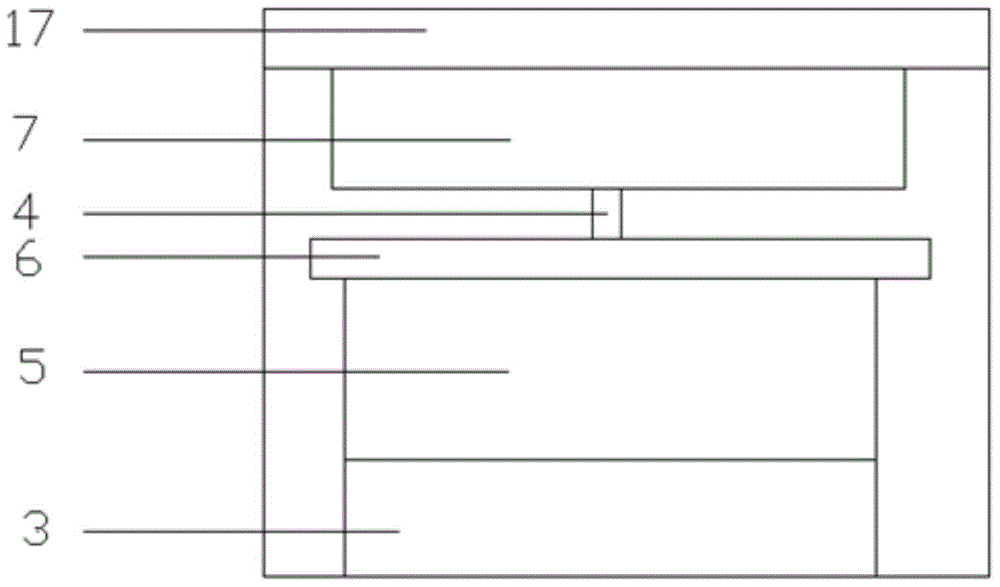

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

[0030] refer to figure 1 and figure 2 , the test aging asphalt production device of the present invention includes a temperature box, a controller 9 and a circulation component; , the controller 9 is located on the outer side of the temperature box, the temperature box is provided with a door 19, the asphalt flow tank 6, the collection bucket 16, the pressure pump 3 and the heating element 8 are located in the temperature box, the entrance of the upper end of the asphalt holder 7 Pass the top of the temperature box and extend out of the temperature box. The inlet of the pressure pump 3 is connected with the bottom of the collection bucket 16, the outlet of the pressure pump 3 is connected with the inlet of the side of the asphalt holder 7, and the bottom of the asphalt holder 7 The outlet of the asphalt flow tank 6 is located directly above the asphalt flow tank 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com