A copper wire pay-off device capable of effectively reducing frictional force

A pay-off device and friction force technology, applied in the field of copper wire pay-off device, can solve problems such as easy peeling off or wear of insulating paint, easy short circuit of finished stator coil, easy stretching and thinning of copper wire, etc., so as to achieve small damage to copper wire , Simple structure, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

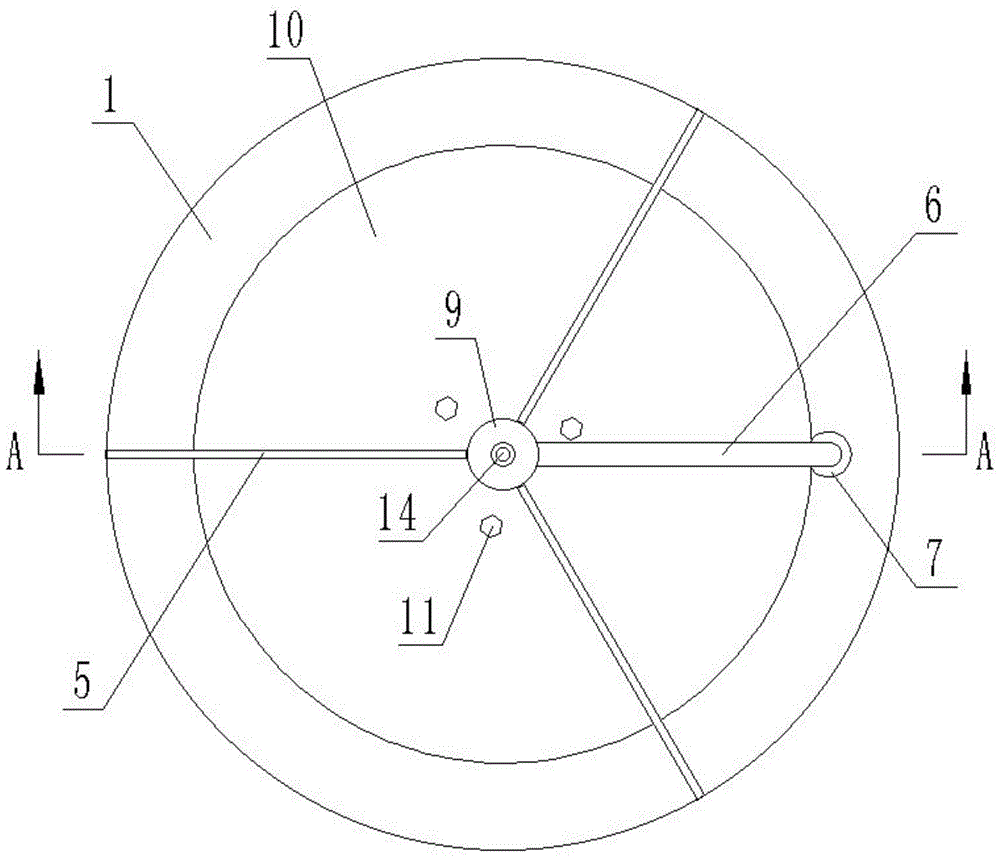

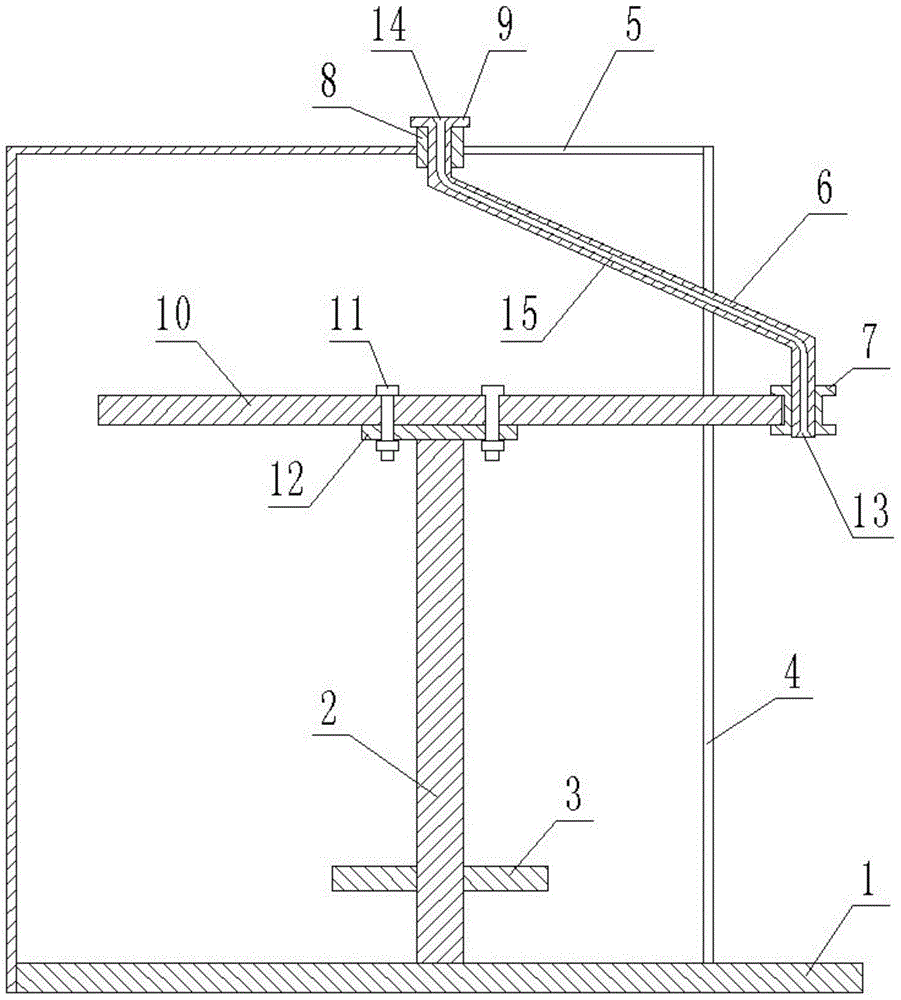

[0024] Embodiment: When in use, first disassemble the locking bolt 11, take off the top plate 10, then fit the I-shaped wheel wound with copper wire on the pillar 2, and adjust the height of the tray 3 so that the top surface is in line with the bottom of the I-shaped wheel. The end faces are offset to complete the fixing of the I-shaped wheel, and then the top plate 10 is reinstalled on the connecting plate 12 and the locking bolt 11 is tightened. Pull the copper wire head out from the I-shaped wheel and then insert it into the copper wire channel 15 through the copper wire inlet 13. The copper wire passes through the copper wire channel 15 and is drawn out from the copper wire outlet 14, and then the copper wire head is delivered to the winding machine. port, the winding of the coil can be started. The winding process will consume the copper wire, and the copper wire will be gradually pulled out from the I-shaped wheel. The center rotates to meet the requirements of copper w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap