Clutch unit and outer friction plate support

A technology of clutch device and plate support, which is applied in clutches, friction clutches, fluid-driven clutches, etc., and can solve problems affecting the function of clutch devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

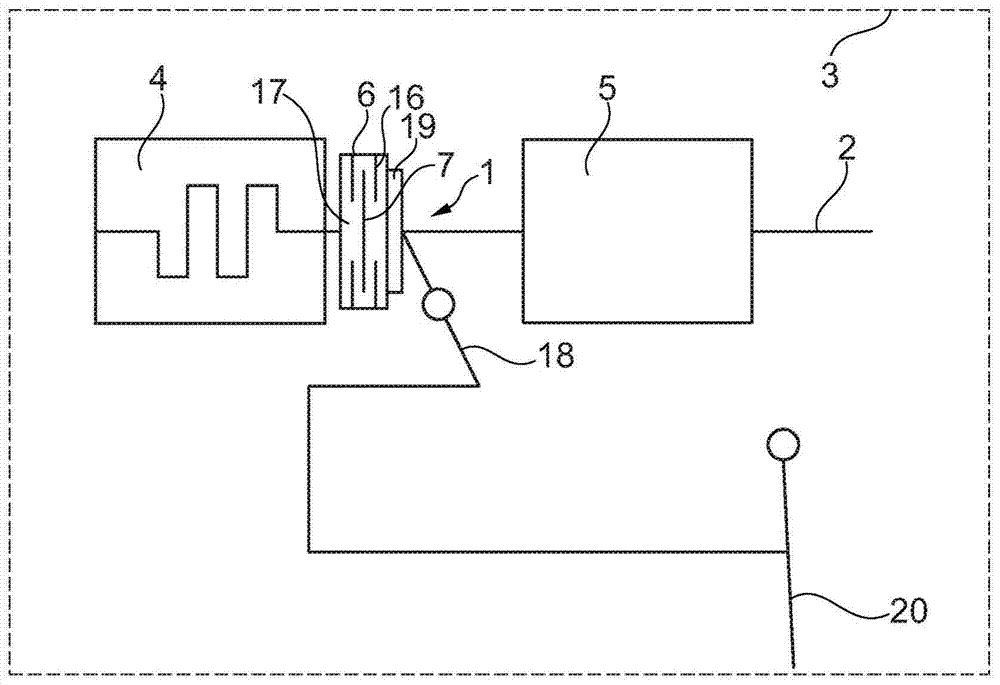

[0035] figure 1 Motor vehicle 3 with clutch device 1 is shown schematically. The clutch device 1 serves to transmit torque between the drive unit 4 and the transmission 5 . The clutch device 1 has an outer friction plate support 6 and an inner friction plate support 7, the outer friction plate support 6 has an outer friction plate 16, the inner friction plate support 7 has an inner friction plate 17, the outer friction plate support 6 and the inner friction plate support 7 can be frictionally connected to each other or disconnected from each other via disk spring 19 and release device 18 . The release device 18 is actuated via a clutch pedal 20 . The torque is transmitted from the drive unit 4 via the clutch device 1 to the transmission 5 and from the transmission 5 to the drive train 2 .

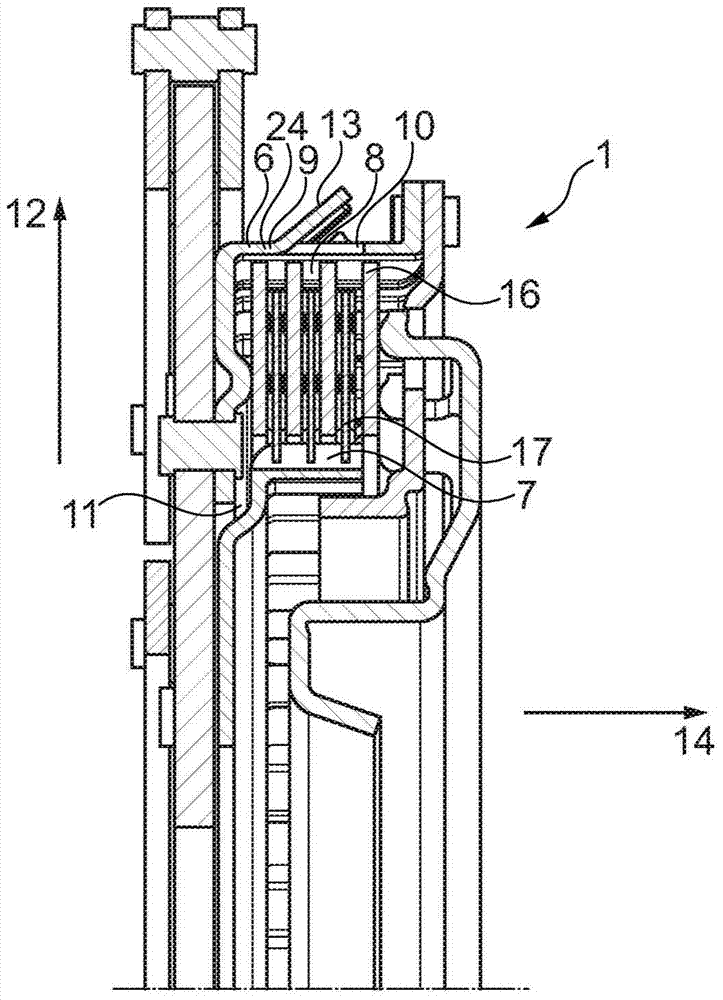

[0036] figure 2A side view of the clutch device 1 is shown in section. The clutch device 1 has an outer disk carrier 6 and an inner disk carrier 7 . The outer disk carrier 6 is posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com