Chain Joints for Links

A technology of chains and links, applied in tow chains, hanging chains, chain buckles, etc., can solve the problems of wasting and cutting off links, increasing the use of raw materials, high cost, etc. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

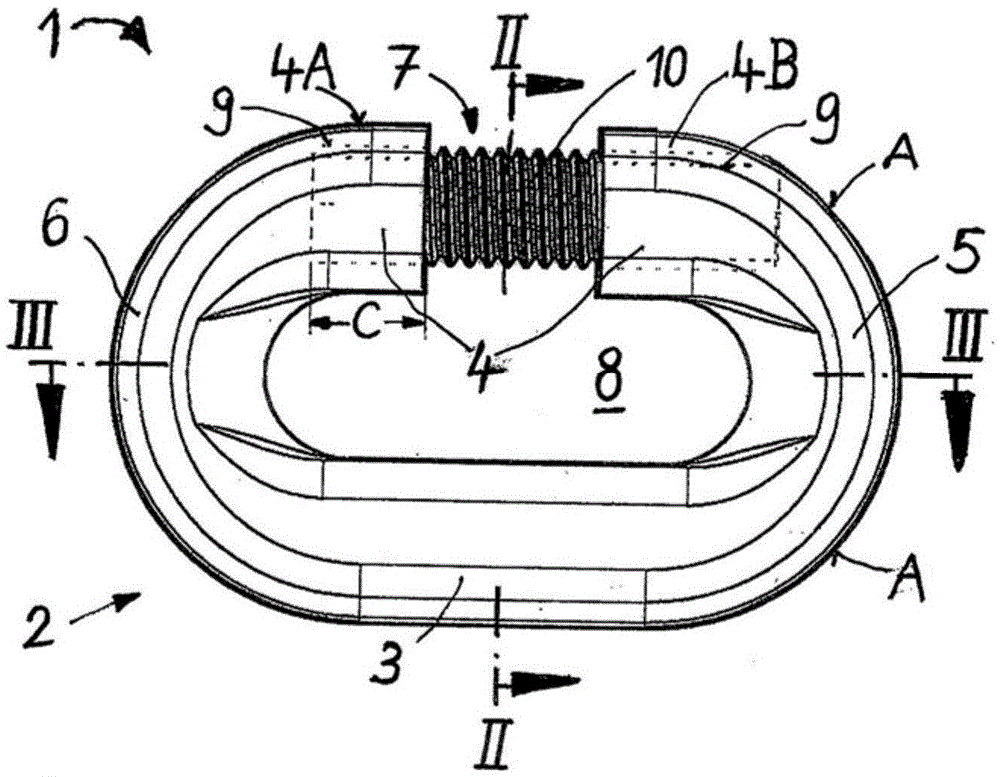

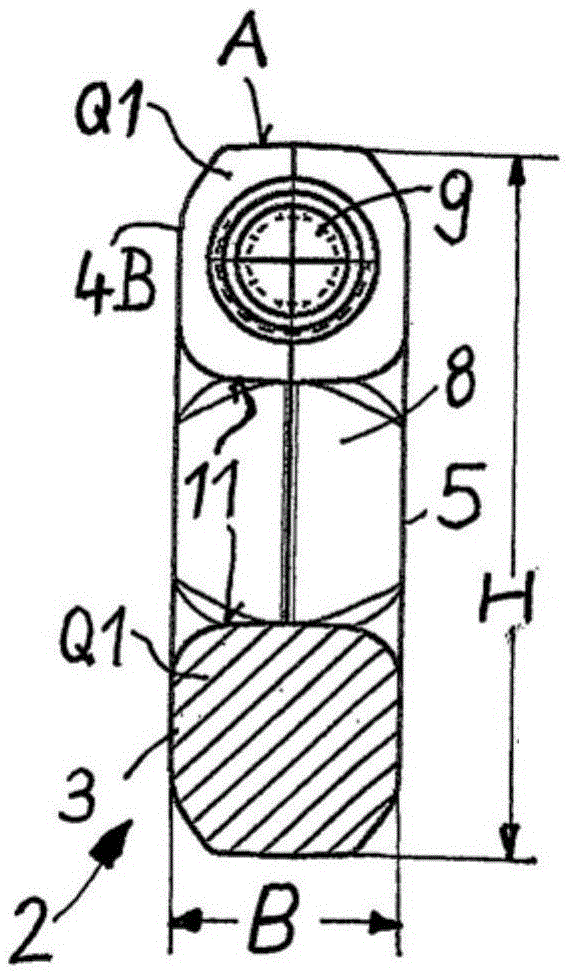

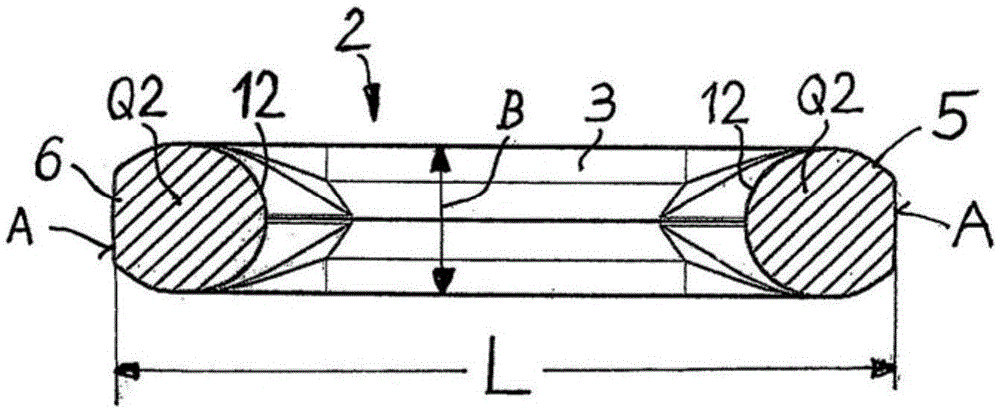

[0019] figure 1 A side view is shown of a chain joint 1 having a main body 2 designed substantially in the form of an oval link, the main body 2 comprising two longitudinal arms 3, 4 parallel to each other, each longitudinal arm via Bent loops 5 , 6 are connected to each other at their ends, wherein in the illustrated embodiment they are shown in side view forming a semicircle.

[0020] in one of the two longitudinal arms, i.e. in figure 1 Longitudinal arm 4 indicated at the top, a receiving opening 7 is formed in the middle which, when open, allows the oval link to be hooked to the inner opening 8 surrounded by the chain joint 1 or its body 2 .

[0021] as from figure 1 and especially from Figure 4 It can be seen from the Figure 4 show figure 1 The three-dimensional diagonal representation of the main body 2 of the chain joint 1, the receiving opening 7 is attached to the middle part on the longitudinal arm 4 and is bounded by the longitudinal arm parts 4A and 4B respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com