Automatic crab tying machine

A crab binding machine and automatic technology, applied in the processing of crustaceans, packaging, slaughtering, etc., can solve the problems of limited operating speed, slow response of operators, muscle soreness, etc., to improve processing efficiency, improve crab binding efficiency, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

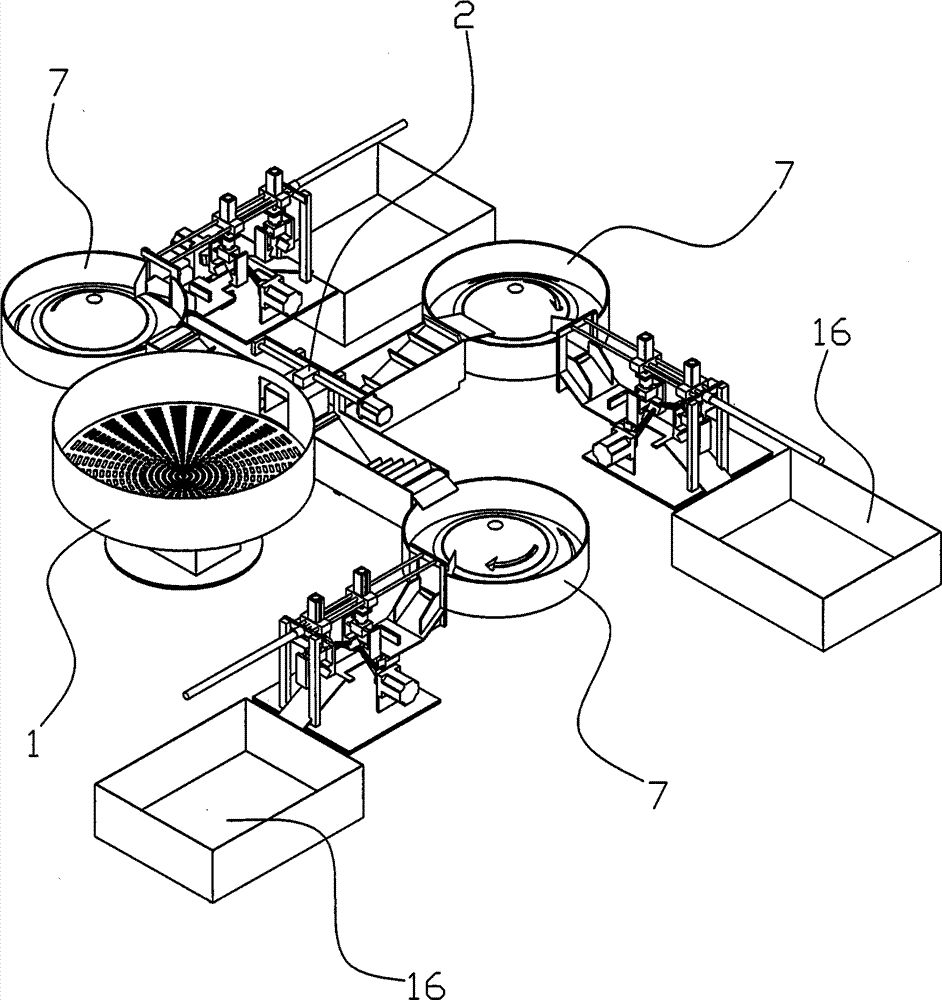

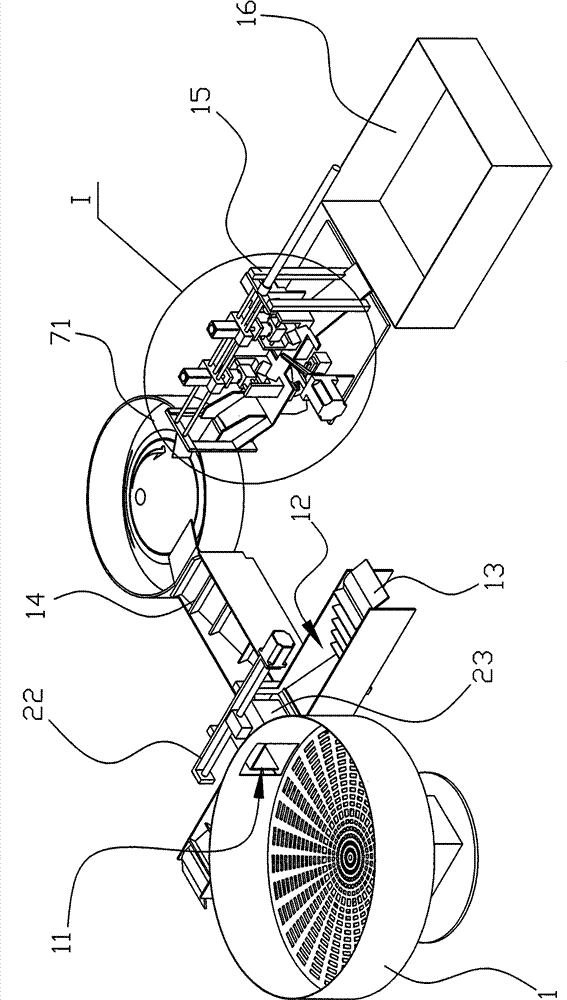

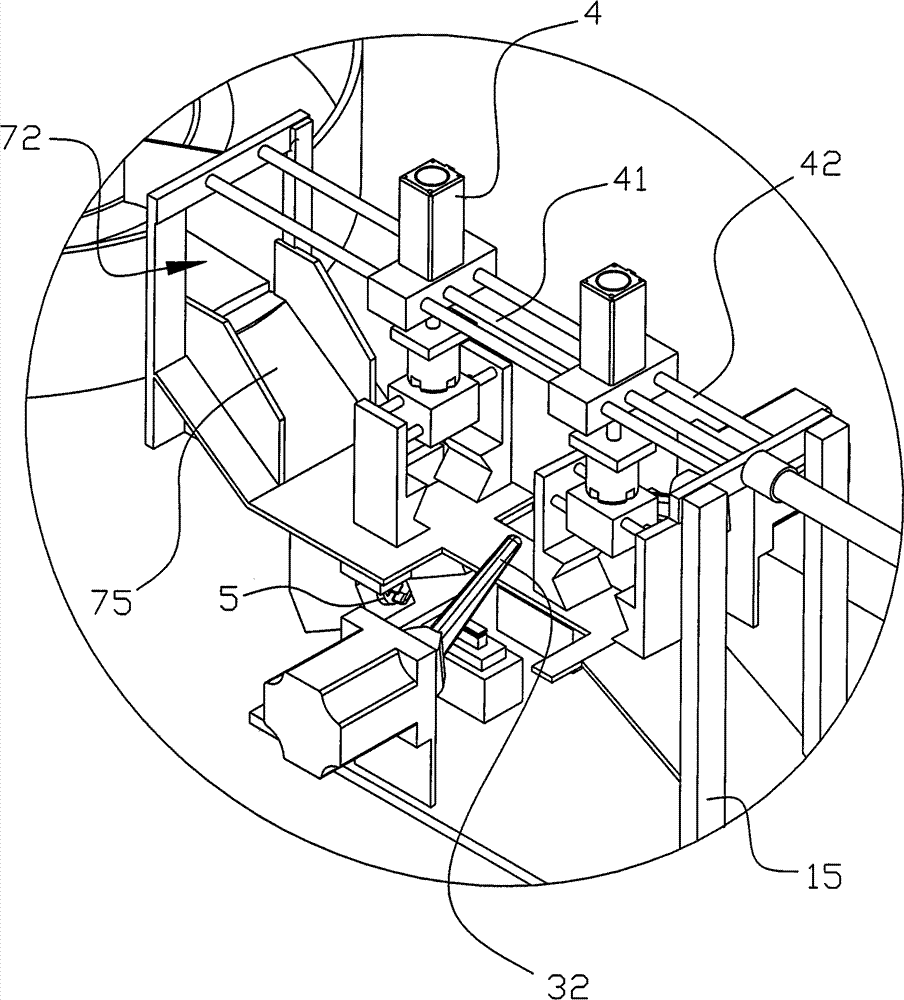

[0036] Such as Figure 1 to Figure 20 As shown, the automatic crab binding machine of this embodiment includes a barrel 1 for placing live crabs, a separation device 2 for separating large and small crabs, an anesthesia pool 12, and an intoxicating tank for storing crabs 3 after they are anesthetized. Crab storage tube 7, drunk crab automatic binding device, storage crab storage tube 16 for drunk crabs after being tied up, an opening 11 through which live crabs can pass is provided on the side of the barrel 1, and the separation device 2 can separate the crabs from The crab 3 crawled out in the opening 11 is placed by weight in the corresponding anesthesia pool 12 of the left, right or front, and the corresponding anesthesia pool 12 of the left, right or front is connected with the corresponding drunk crab storage cylinder 7 respectively, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com