A coaxial counter-rotating propeller pitch changing device

A technology of pitch changing device and propeller, which is used in propeller, transportation and packaging, aircraft parts, etc., can solve the problem of not meeting the requirements of coaxial counter-rotating propeller pitch change, and achieve light weight, fast response speed and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

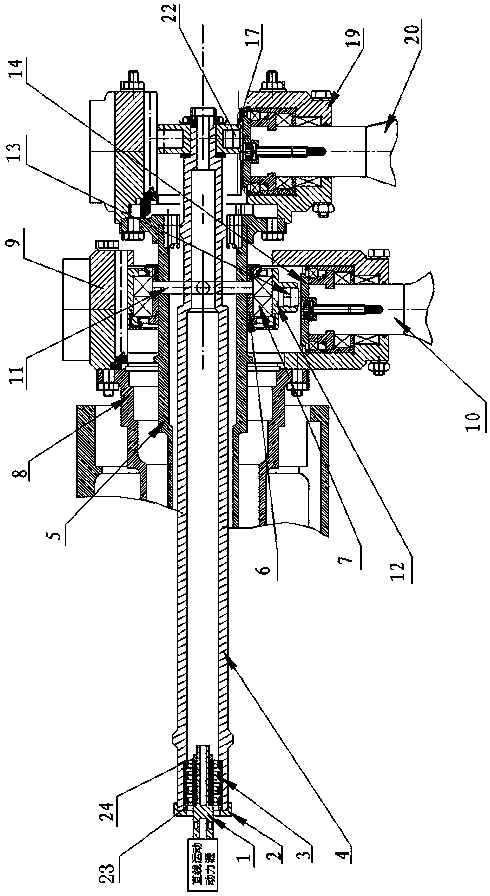

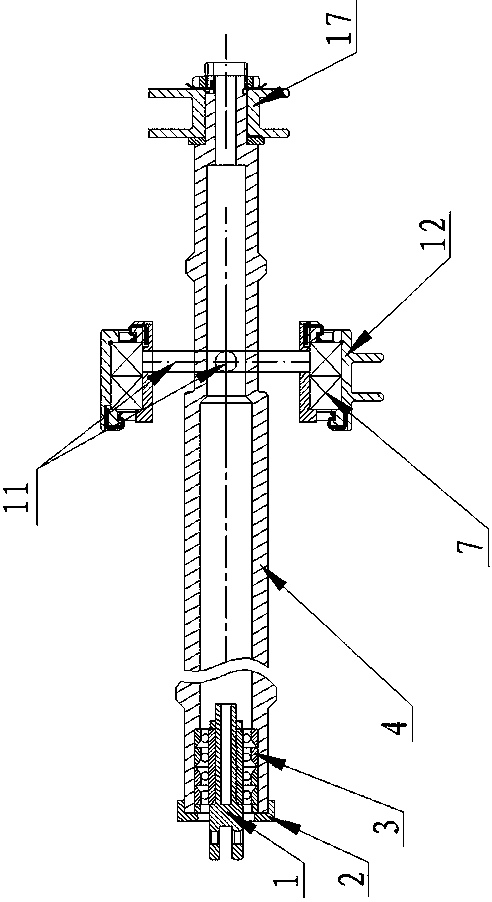

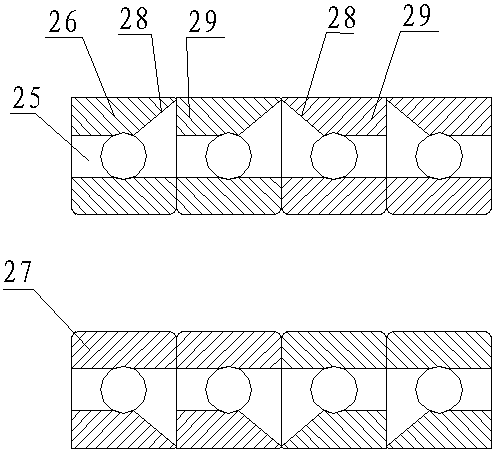

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the present embodiment includes a linear motion power source, a fork lug 1, a bearing retaining ring 2, a static and dynamic conversion bearing 3, a pitch change rod 4, a pin 11, a high-speed bearing 7, front and rear dial sleeves 17 and 12, front, Rear eccentric pins 13 and 22. The pitch change rod 4 is passed through the center hole of the inner shaft 5 of the engine reducer, and its front end and the front dial 17 are fixed together by washers and nuts, and each shift fork on the front dial 17 is fixed to each front eccentric pin through bearings. 22, each front eccentric pin 22 is respectively eccentrically fixed on the paddle root retaining ring 14 of each front blade 20. A pin 11 is plugged and fixed on the pitch-changing rod 4 facing the rear dial sleeve 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com