Semi-autonomic zongzi wrapping machine

A semi-automatic, rice dumpling machine technology, applied in the direction of wrapping objects, packaging/bundling objects, packaging, etc., can solve the difficult to achieve short-term, large-volume, high-quality supply requirements, high skill requirements for workers, low production efficiency, etc. problems, to achieve the effect of reasonable utilization and configuration, avoiding excessive contact, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

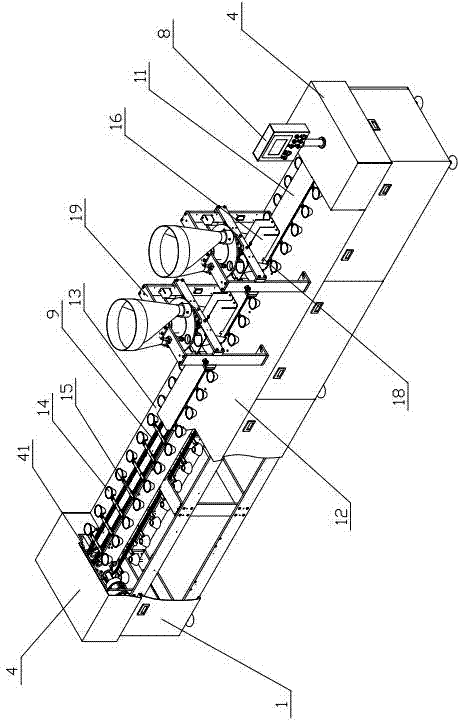

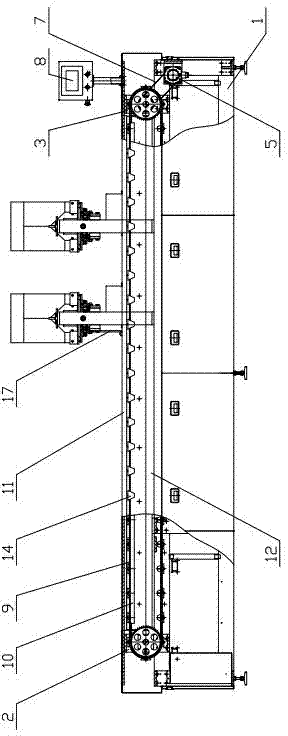

[0028] Such as figure 1 and figure 2 As shown, the semi-automatic rice dumpling wrapping machine of the present embodiment includes a frame 1, a working surface assembly is installed above the frame 1, and a main transmission mechanism is installed in the middle of the working surface assembly. Two sets of rice supply devices are installed above the working surface; a control box 8 is installed above one end of the main transmission mechanism, and a blanking control system and an emergency switch 36 are installed on the rice supply device.

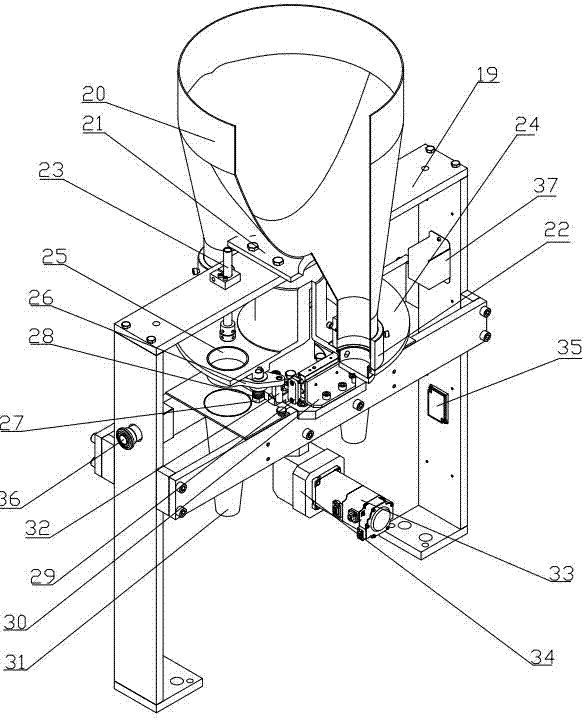

[0029] Such as image 3 Shown, the structure of rice supply device is: comprise support frame 19, on the top plate of support frame 19, hopper 20 is fixed by mounting plate 21, is positioned at the middle plate of support frame 19 and rotating disk 24 is installed, and rotating disk 24 is driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com