Drive swing shaft sleeve

A technology of oscillating shafts and shaft sleeves, which is applied in the field of packaging units, can solve the problems of reduced production efficiency, damage to the driving arm, poor wear resistance and poor strength, etc., and achieve the effects of improving the strength of the workpiece, improving the structure, and increasing the driving torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

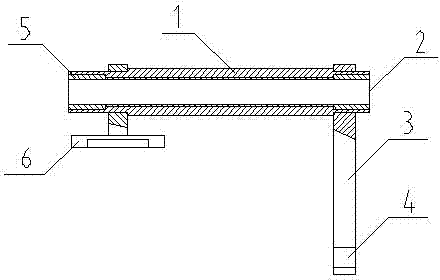

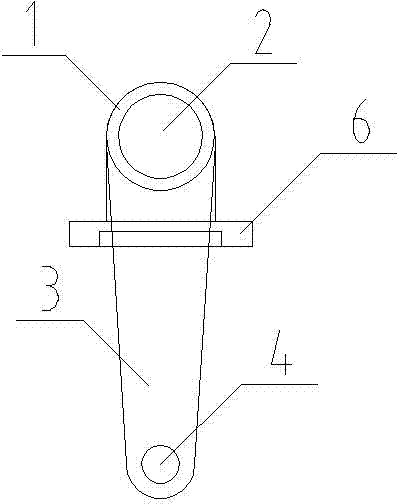

[0013] A drive swing sleeve shaft, including a shaft sleeve (1), characterized in that ball bearings (5) are installed on both sides of the shaft hole (2) of the shaft sleeve (1), and the shaft sleeve (1) A drive connecting rod (3) is welded on one side, and a drive disc (6) is welded on the other side of the bushing (1). The drive disc (6) is a disc structure and has a cylindrical stepped hole. The drive connecting rod (3) has a circular arc structure at both ends of the connecting rod, and a connecting hole (4) is opened at the lower end.

[0014] The driving source pushes the drive connecting rod (3). Since the bushing (1) is connected to the round shaft through the ball bearing (5), the driving connecting rod (3) rotates around the round shaft to drive the bushing (1) to rotate. At this time The drive disc (6) fixed on the other end of the shaft sleeve (1) also rotates together with the shaft sleeve (1), and the drive disc (6) can drive other structures to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com