Overturning type logistics box

A logistics box and flip-type technology, which is applied in the field of transportation equipment and flip-type logistics boxes, can solve the problems of easy loss of small parts, cumbersome carrying, and high cost, so as to save space and transportation costs, reduce box circulation costs, assemble and Stackable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. It should be understood that the examples are illustrative only and not limiting.

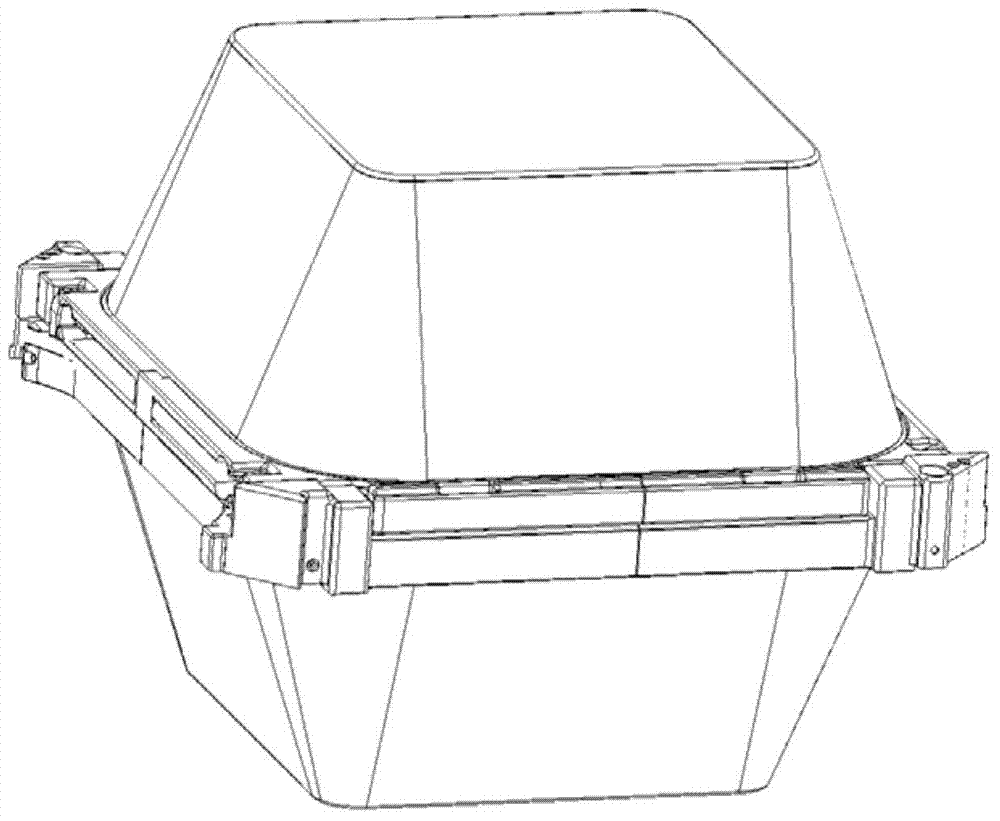

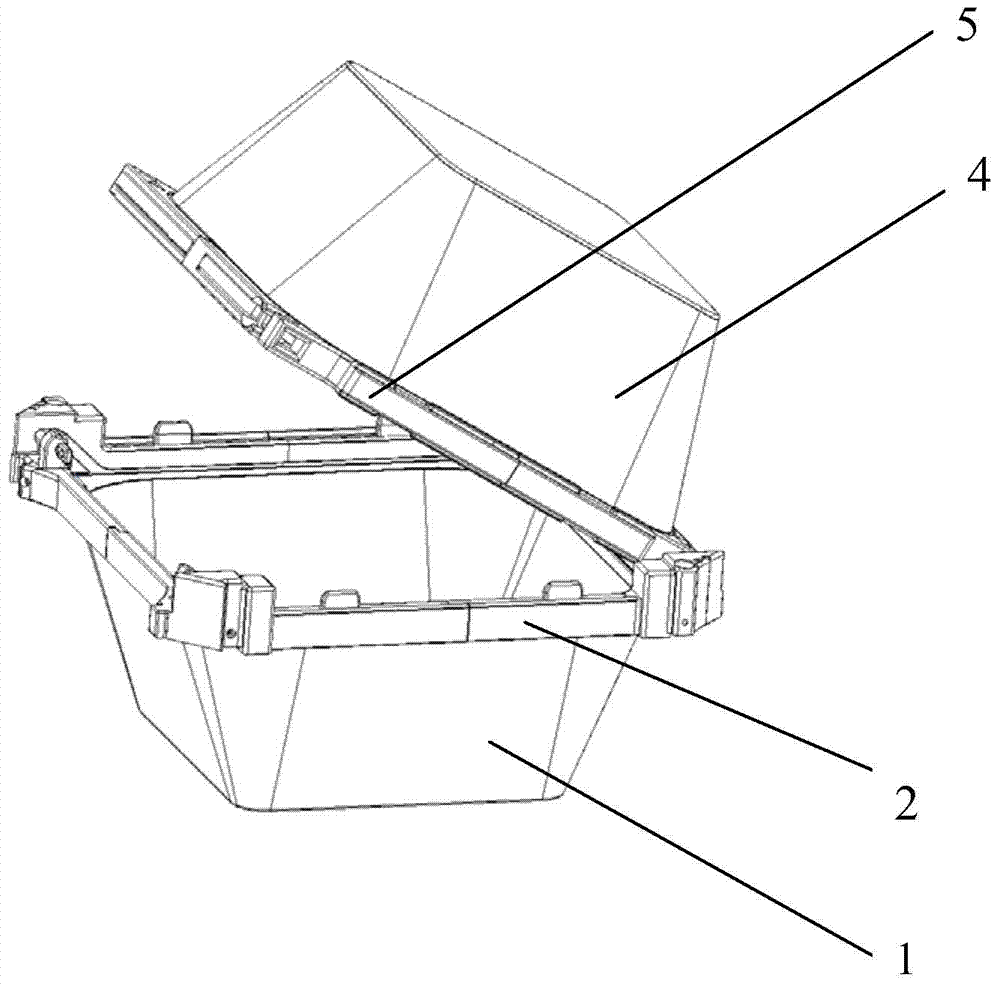

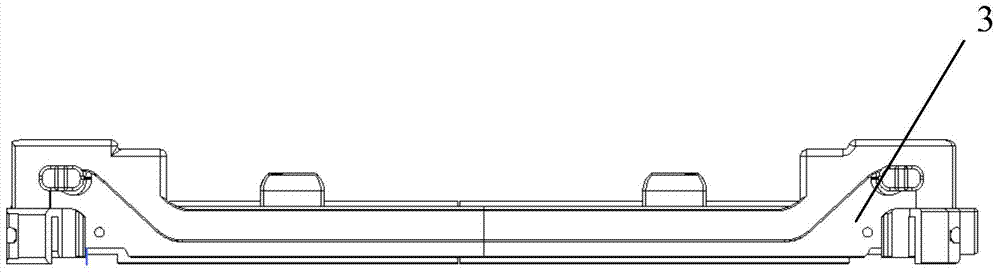

[0033] See Figure 1 to Figure 10 As shown, the flip-type logistics box of the present invention includes a box cover part and a box body part, wherein the box body part includes a box body 1 and a box body frame 2 fixed at the mouth of the box body 1, and the box body frame 2 is parallel to each other. Two grooves 3 parallel to each other are provided on the inner sides of the two frames; the cover part includes the cover 4 and the cover frame 5 fixed on the mouth of the cover 4, and is provided along one side of the cover frame 5 The turning shaft 6, the two end points of the turning shaft 6 are respectively embedded in the two parallel grooves 3 and slide in the two parallel grooves 3.

[0034] The box frame 2 and the box 1 are fixed by clamping. The botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com