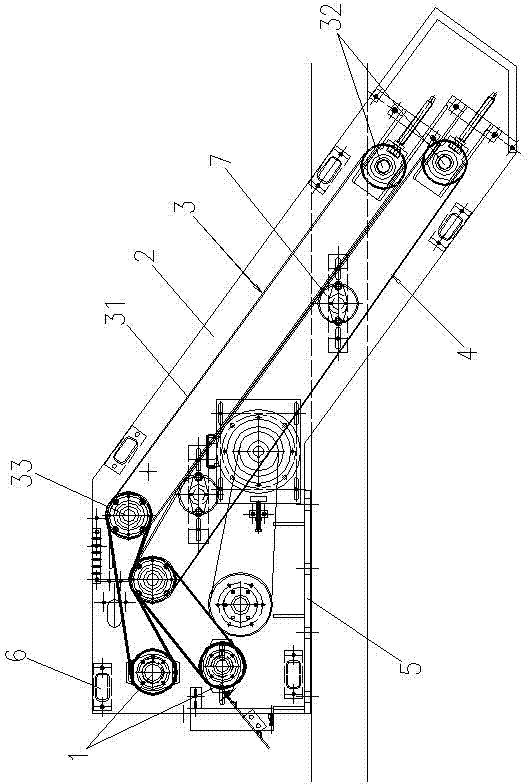

Integral type traction device

A traction device and integrated technology, applied in the field of corrugating machine equipment structure, can solve the problems of the upper and lower traction device matching deviation, the complex structure of the traction device, the wrong length of the conveyor belt, etc., and achieve high installation accuracy, easy installation and debugging, and reduce production time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] In practical applications, the complete traction support plate 2 is connected and fixed by installing the connection base plate 5 and the connection support pipe 6, and the complete set of upper conveyor belt assembly 3 and lower conveyor belt assembly 4 are fixed and installed according to the installation holes on the traction support plate 2 , the conveyor belt 31 is compressed by the tensioning device 32 and the tension roller 7, the drive motor 1 is installed, and the upper conveyor belt assembly 3 and the lower conveyor belt assembly 4 are connected through the transmission belt device. Finally, the whole set of traction device is installed and placed on the main beam of the frame to complete the whole set of assembly process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com