Full-bundle conveyor of prestressed steel strand

A technology of prestressed steel strands and conveyors, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc. beam quality and other issues, to achieve the effect of high conveying efficiency, good conveying quality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

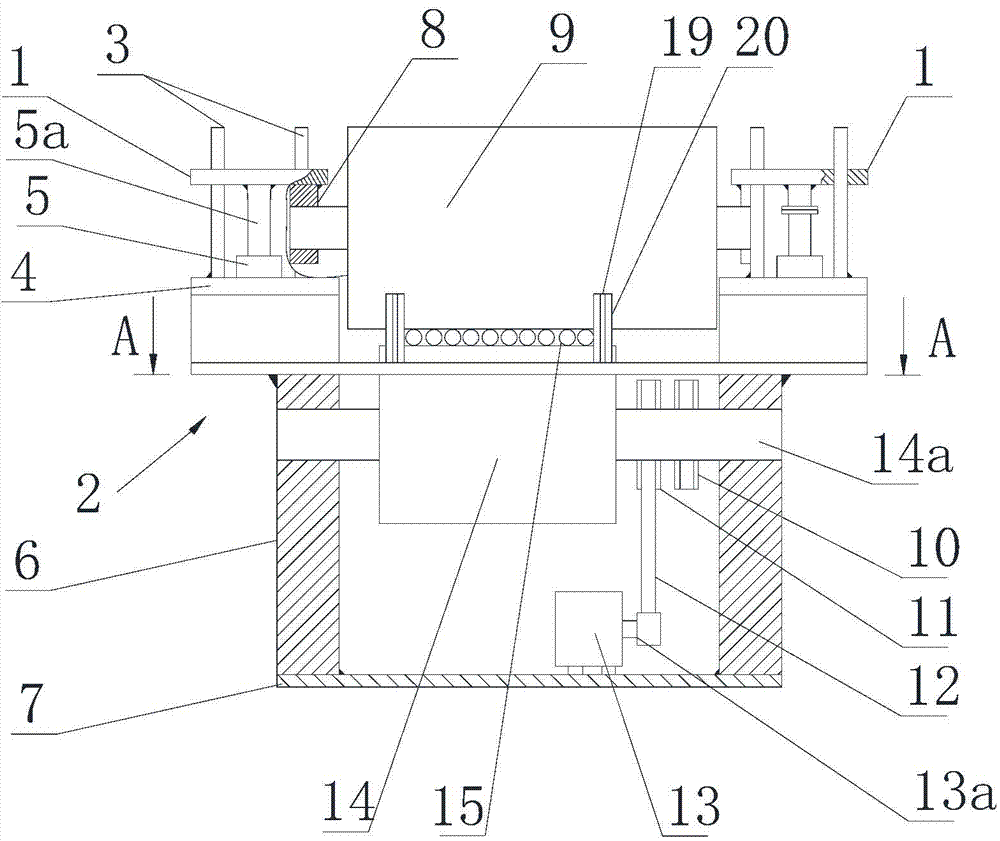

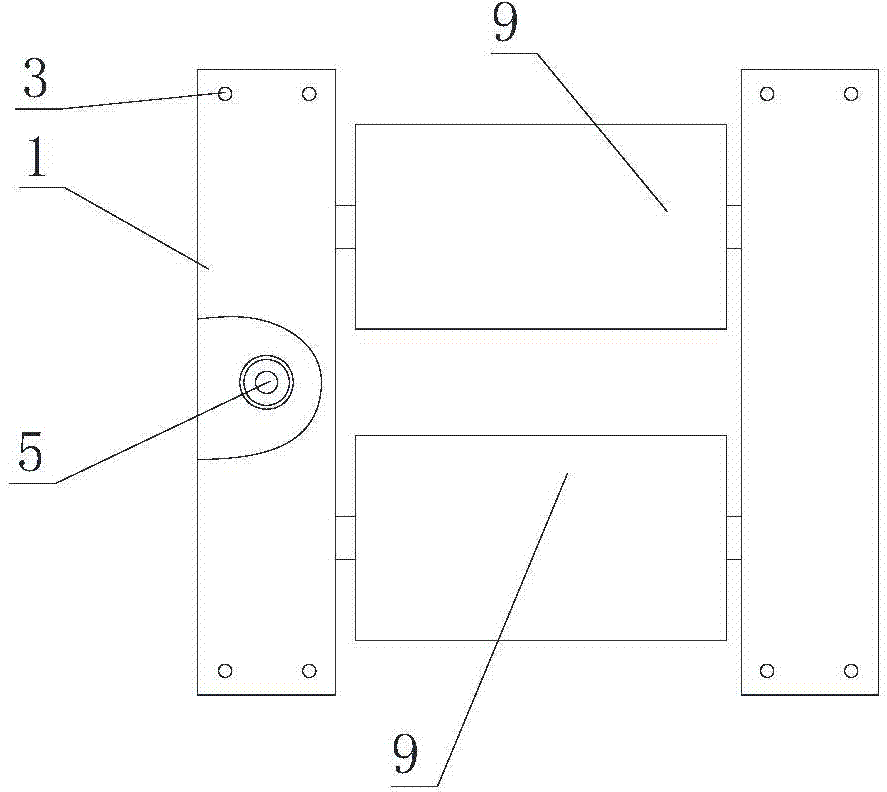

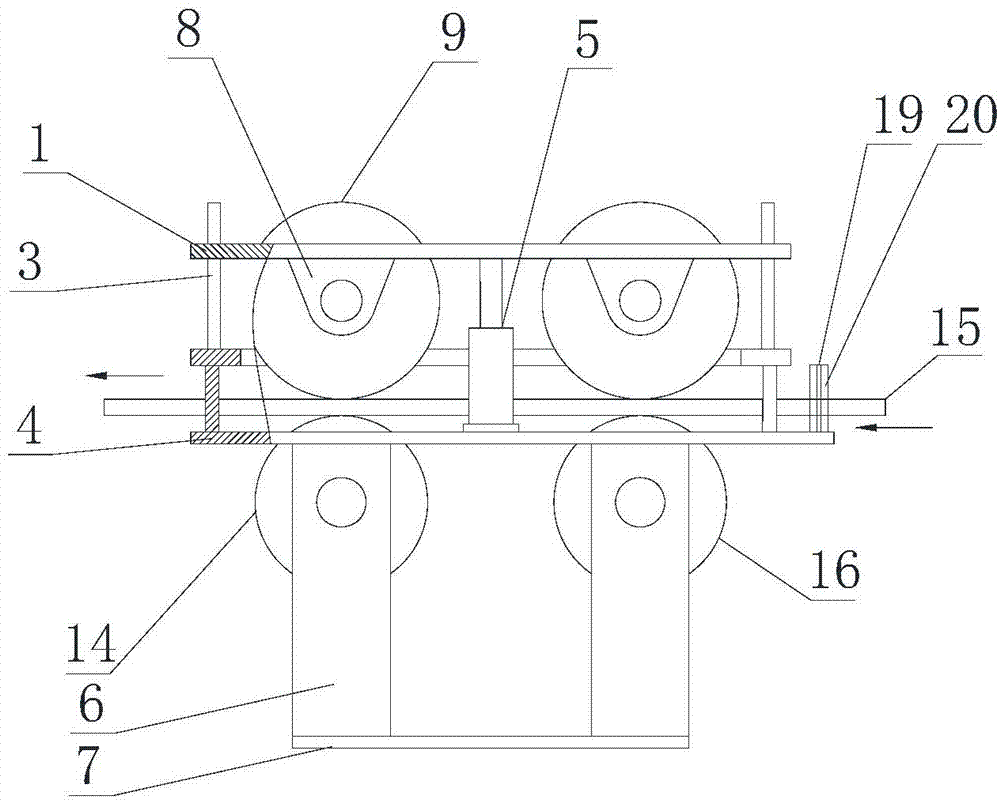

[0018] The present invention provides a whole-bundle conveyor for prestressed steel strands. The whole-bundle conveyor includes: a frame 2, two driven rollers 9 with the same structure are arranged side by side on the upper part of the frame 2, two driven rollers 9 The two ends of the roller 9 shafts are respectively hinged on the sliding brackets 1 with the same structure and symmetrical positions, and the bottom surfaces of the middle parts of the two sliding brackets 1 are respectively connected to the piston rods 5a of the cylinder 5 and are supported by the piston rods 5a. The cylinder blocks are respectively fixed on the frame 2, and there are a plurality of holes on both sides of the sliding bracket 1 to slide on the column 3, and the plurality of columns 3 are fixed on the frame 2, and two cylinders 5 respectively drive the sliding bracket 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com