Spinning reel

A reel and textile technology, applied in the field of auxiliary accessories for textile machines, can solve the problems of inconvenient installation, difficult to correct, limited space at the elliptical swivel, and achieve the effects of convenient installation, concentrated and accurate traction direction, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

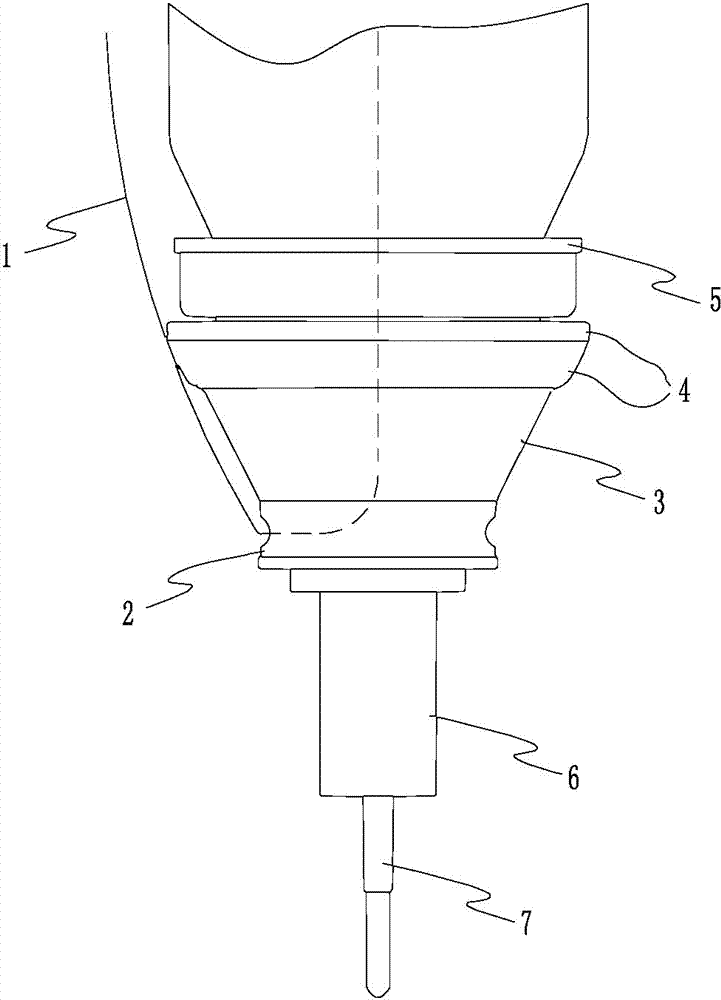

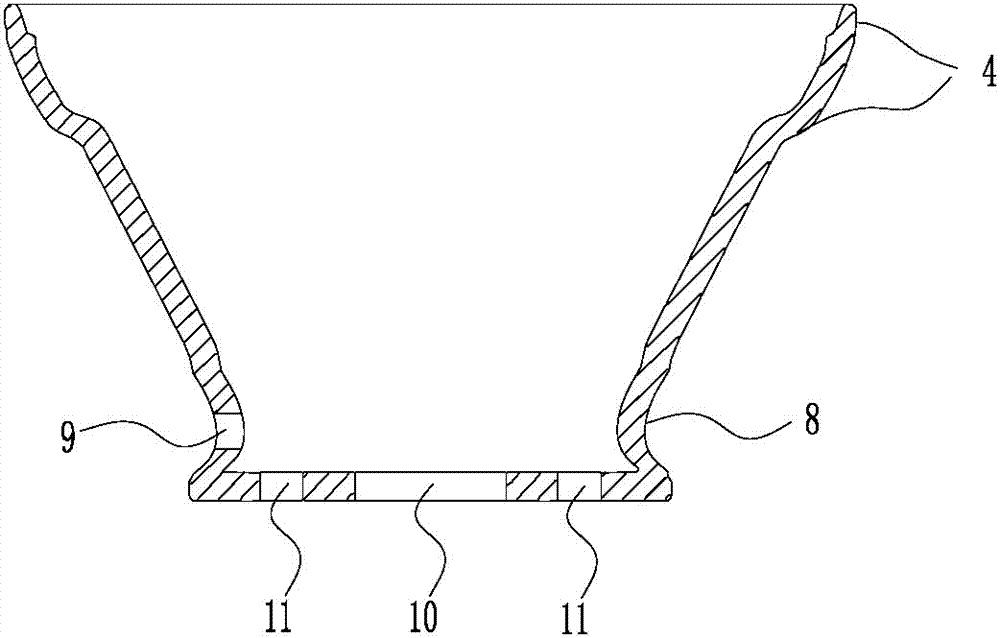

[0021] The reference signs in the drawings of the description include: line 1, lower curved block 2, middle taper sleeve 3, ring platform 4, upper support ring 5, mounting seat 6, connecting shaft 7, indentation area 8, through hole 9, opening Hole 10, winding hole 11.

[0022] Such as figure 1 As shown, the utility model textile winding 1 wheel includes an elliptical swivel body and a support sleeve arranged below the elliptical swivel body, and the lower part of the elliptical swivel body is rotatably connected with the inner wall of the support sleeve through a bearing.

[0023] Bearings can be set using existing basic structures, such as rolling bearings including outer rings, inner rings, rolling elements and cages.

[0024] The supporting sleeve includes an upper support ring 5, a middle taper sleeve 3 and a lower curved block 2 arranged in sequence from top to bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com