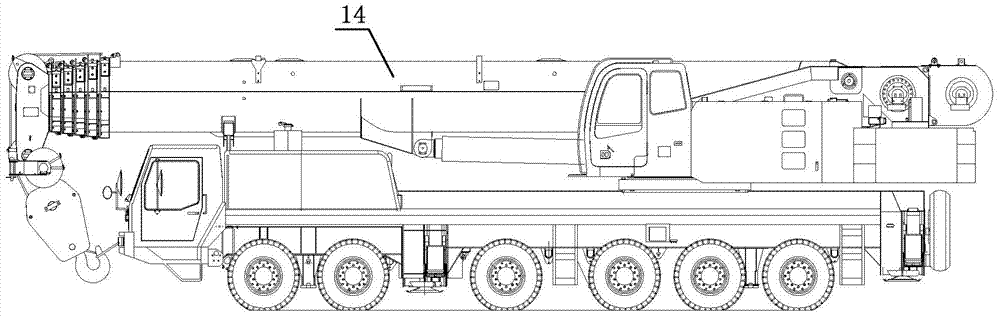

Telescopic boom and crane

A boom and telescopic technology, which is applied in the field of telescopic booms and cranes, can solve the problems of strict return spring requirements and large return force, and achieve the effect of reducing requirements and small return force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

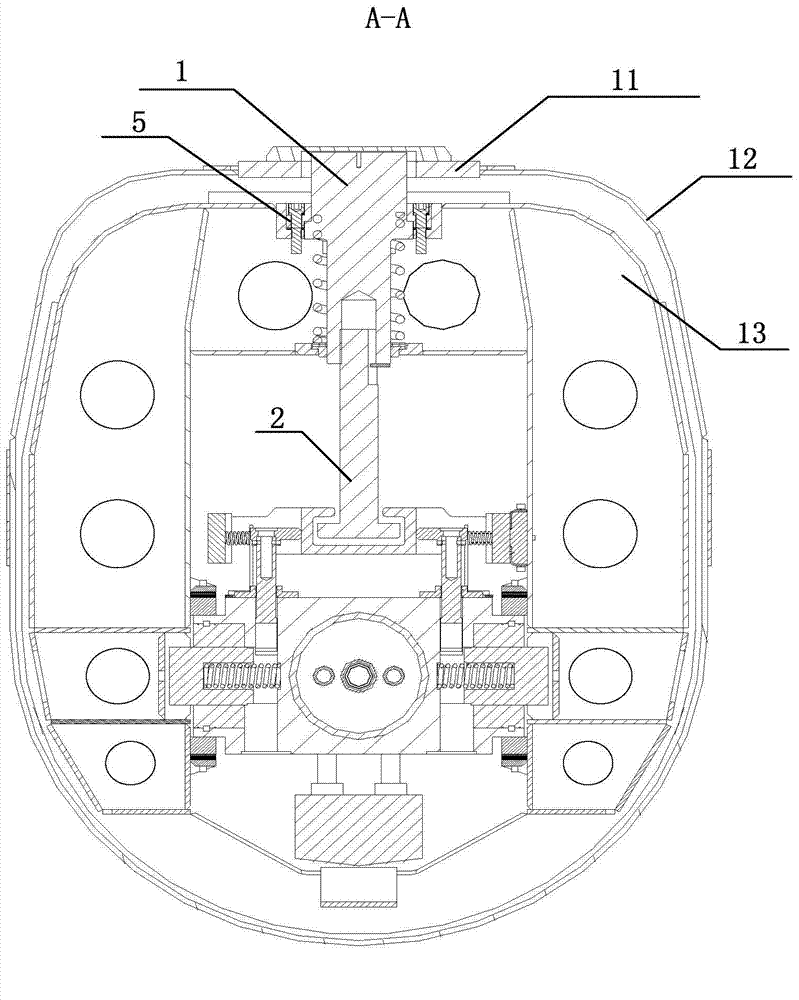

[0061] Combine below Figure 6 ~ Figure 13 A more detailed elaboration of the technical solution provided by the present invention, a technical solution obtained by replacing any technical means provided by the present invention or combining any two or more technical means or technical features provided by the present invention with each other All should be within the protection scope of the present invention.

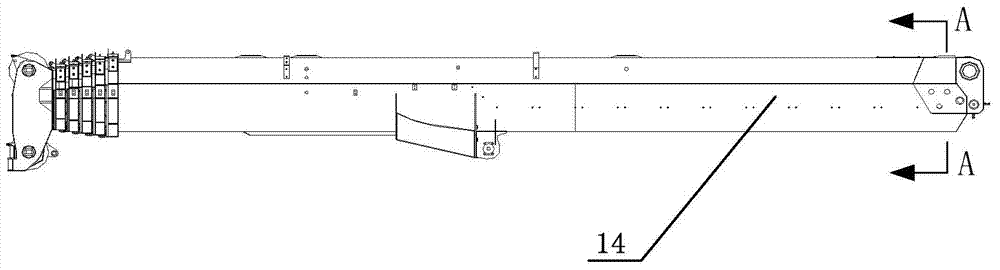

[0062] see Figure 6 ~ Figure 8 , the embodiment of the present invention provides a telescopic boom, including at least two mutually socketed telescopic booms 20; an arm pin structure 21 is arranged between two adjacent telescopic booms 20, and the arm pin structure 21 is located at each The side of telescopic arm 20.

[0063] There are various structural forms of the arm pin structure 21, and existing structures or optional structures given below can be used.

[0064] Different from the scheme of placing the arm pin system on top in the prior art, the telescopic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com